Fast & affordable prototyping

-

Dimensional accuracy of ± 0.5% with a lower limit: ± 0.5 mm

-

Lead times from 1 business day

We manufacture high-quality, competitively priced custom prototypes & production parts. Upload a CAD file for an instant 3D printing quote. Order parts in 5 minutes from your desk.

Get an instant 3D Printing quote All uploads are secure and confidentialWe have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

Fast & affordable prototyping

Dimensional accuracy of ± 0.5% with a lower limit: ± 0.5 mm

Lead times from 1 business day

Functional prototyping & low-run production

Dimensional accuracy of ± 0.3% with a lower limit of ± 0.3 mm (± 0.012")

Lead times from 3 business days

Functional prototyping & low-run production

Dimensional accuracy of ± 0.3% with a lower limit of ± 0.3 mm (± 0.012")

Lead times from 3 business days

Visual prototyping

Dimensional accuracy of ± 0.3% with a lower limit of ± 0.3 mm (± 0.012")

Lead times from 2 business days

Fused deposition modeling (FDM) 3D printing is one of the most popular additive manufacturing processes on the market today. Using thermoplastic polymers that come in the form of filaments, FDM builds parts layer by layer by selectively depositing melted material along a path determined by Gcode. FDM printing is fast, accurate, and cost-effective, and requires minimal post-processing for support structure removal. With FDM, you can use desktop machines for initial and functional prototyping as well as industrial printers for custom end-use parts. As a material extrusion technology, FDM printing produces durable, rigid components in a variety of plastic materials, including ABS, PLA, PETG, ULTEM, and Nylon. While functional and cosmetic properties depend on the material you select, FDM parts have high strength and can be geometrically complex.

For more information on FDM 3D printing, read our

introduction to the process or learn

how to design better parts for FDM.

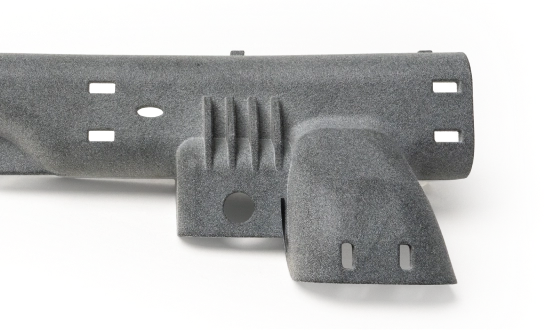

Selective laser sintering (SLS) 3D printing is one of the most powerful additive manufacturing processes, capable of producing durable and accurate custom parts. SLS 3D printing is ideal for rapid prototyping and functional prototyping, end-use parts, and low-volume production, and more companies are turning to SLS for more industrial applications. Instead of extruding plastic filament, SLS printers use a laser to selectively fuse plastic powders into solid models layer-by-layer. These machines scan cross-sections on the surface of a powder bed with Gcode from your CAD files. After scanning a cross-section, SLS printers lower a powder bed by one layer and deposit more material on top of what’s already been sintered. This process repeats until you have a finished part. SLS 3D printing is a speedy way to produce functional parts from engineering materials including Nylon 12 (PA 12) and Glass-filled Nylon (PA 12 GF).

For more info on SLS 3D printing, check out our

introduction to the technology and learn

how to design better parts for SLS.

Multi Jet Fusion (MJF), HP’s proprietary additive manufacturing process, is the most advanced 3D printing technology available today. It’s capable of producing complex functional prototypes and mechanically impressive end-use components quickly and with high degrees of accuracy. MJF 3D printed parts are durable, even with intricate features, and have isotropic mechanical properties. Compared to other additive technologies that use powder bed fusion, MJF is speedy and capable of more industrial applications and is often a viable alternative to injection molding for low-volume production runs. In many industries, MJF is the go-to process for producing electronic component housings, mechanical assemblies, enclosures, and jigs and fixtures. MJF 3D printing is currently a proprietary technology and can only create parts from HP PA 12 and HP PA 12GF.

For more information on MJF 3D printing, check out our

introduction to the technology and learn

how to design better parts for MJF.

Stereolithography (SLA) 3D printing is an additive manufacturing process offering impressive accuracy and high resolution. It’s an ideal solution for quickly manufacturing initial and functional prototypes and end-use parts in low volumes. Part of the vat photopolymerization class of additive technologies, SLA uses UV lasers to selectively cure polymer resins one layer at a time. The materials used in SLA are photosensitive thermoset polymers that come in a liquid resin form, with specialty materials available like clear, flexible, and castable resins. SLA 3D printed parts are smooth to the touch and can be finely detailed, making the process an ideal choice for visual prototypes. For some applications, SLA can even stand in for injection molding, especially if you use industrial SLA machines that can print in larger parts with specialty materials.

For more information on SLA 3D printing, check out our

introduction to the technology and learn

how to design better parts for SLA.

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to 3D production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

Price updates in real-time as you change materials, lead time, etc..

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

“Very courteous and printed two of the provided objects. ”

“Excellent service, fast communication, and very helpful through every part of the process. Strives for 100% customer satisfaction”

“Great print quality and customer service.”

“Very happy with print quality and speed. We are interested in knowing max build size for future models. Thank you”

“These parts are perfect! Highly Recommended”

“Product was great, expect specifications and worked perfectly for what they were needed for.”

“Great service again. Parts received as expected.”

“Order was completed early and as expected!”

“Absolutely amazing and high quality 3D prints! I recommend to all! ”

“Great hub, quick service and helpful information.”

“Easy transaction, fast print, fast ship. Part looks exactly as I expected. ”

“Good quality prints, would be willing to use again”

“Exactly the what I ordered and delivered quicker than expected. Knowledgeable. professional, and efficient!”

“The print came out great, the team did a great job with communication and explanation of different materials. Will use them again!”

“I'm absolutely amazed at how quickly this worked. I initially contacted NorVA plastics, just across the street here in Norfolk, I'm still waiting to hear back. Thank you guys! Can't wait to have more 3D stuff printed out. ”

“Very happy with the print quality and service. ”

“Great Printer, Great Communication, Reasonable Prices.”

“I greatly appreciate your promptness and quality of your print. This design is being used as a cell phone holder installed into the console of my Nissan 370Z, whereas otherwise, this car has no other practical place to hold a cell phone. The new install looks like an OEM feature of the console and adequately provides for the intended purpose. Thank you sincerely for your professional service.”

“Great parts. Great experience. I'll be back.”

“The parts look great - thanks for completing this for me!”

“Fast turnaround, and parts turned out great.”

“The prints look great. Much appreciated.”

“Quick turn-around for a prototype! Very affordable! Will use again!”

“Thank you so much for your help and for taking the order! I know it wasn't worth much. It has definitely helped me already!”

“Great service and way faster than expected!”

Protolabs and its network work together to bring you the world's most comprehensive manufacturing solution. While the network can provide a large breadth of capabilities, Protolabs’ factories offer expedited manufacturing with automated in-house machines for the industry's fastest lead times.

Get quick-turn parts with Protolabs

Protolabs Network takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets The Protolabs Network Standard.

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Get practical advice on how to design for 3D printing, based upon first-hand experience from the industry’s leading experts. Click here to download the sample chapters.

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3D printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet The Protolabs Network Standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Stereolithography (SLA).

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D Printing Handbook.

For tips on designing for production, take a look at our key design considerations for 3D printing. Designing models for 3D printing is generally done with CAD software such as Solidworks and Fusion 360, or 3D modeling software such as Blender, Maya or 3Ds max. To learn more see our article on 3D modeling CAD software.

We have an extensive range of online resources developed to help engineers improve their capabilities.

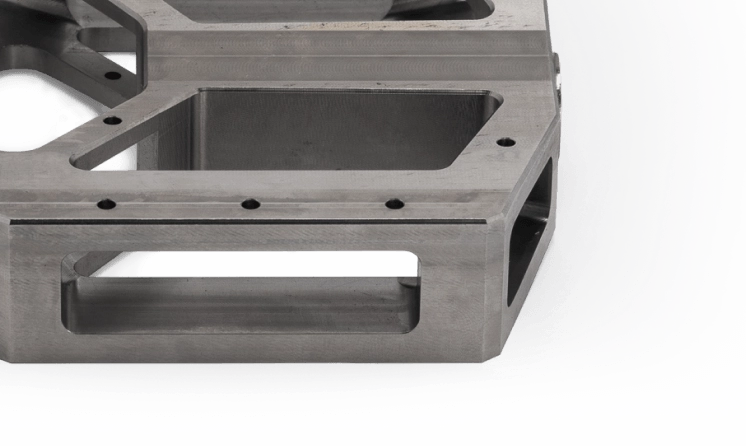

Milling (3-, 4- & full 5-axis), turning and post-processing

50+ metals and plastics & 10 surface finishes

Tolerances down to ±.0008” (0.020 mm)

Lead times from 5 business days

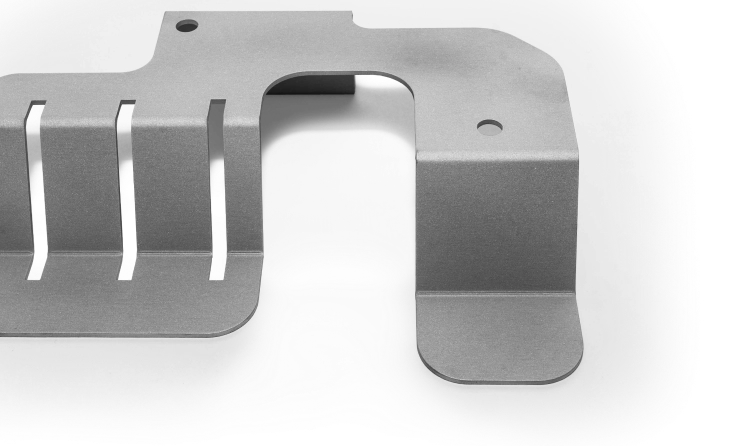

Laser cutting, bending, post-processing

6 metals & 9 surface finishes

Tolerances down to ±.004” (0.010 mm)

Lead times from 5 business days

Prototypes and production tooling

Wide range of part complexities and sizes

1 to 1M parts

Put your 3D printed parts into production today

Get an instant 3D printing quote