Surface finishes

Vapor smoothing services

We offer vapor smoothing as a surface finish for 3D printed parts. Used for a variety of aesthetic purposes, it reduces surface roughness, leaving a smooth, glossy texture that’s easy to clean.

Types of vapor smoothing

| Process | Surface Preparation | Color | Applicable materials | Cosmetic availabilty | Visual appearance |

|---|---|---|---|---|---|

| MJF | As printed | Grey (default), Dyed Black | HP PA 12 | No | Smooth glossy appearance |

| SLS | As printed | White (default), Dyed Black | PA 12 | No | Smooth glossy appearance |

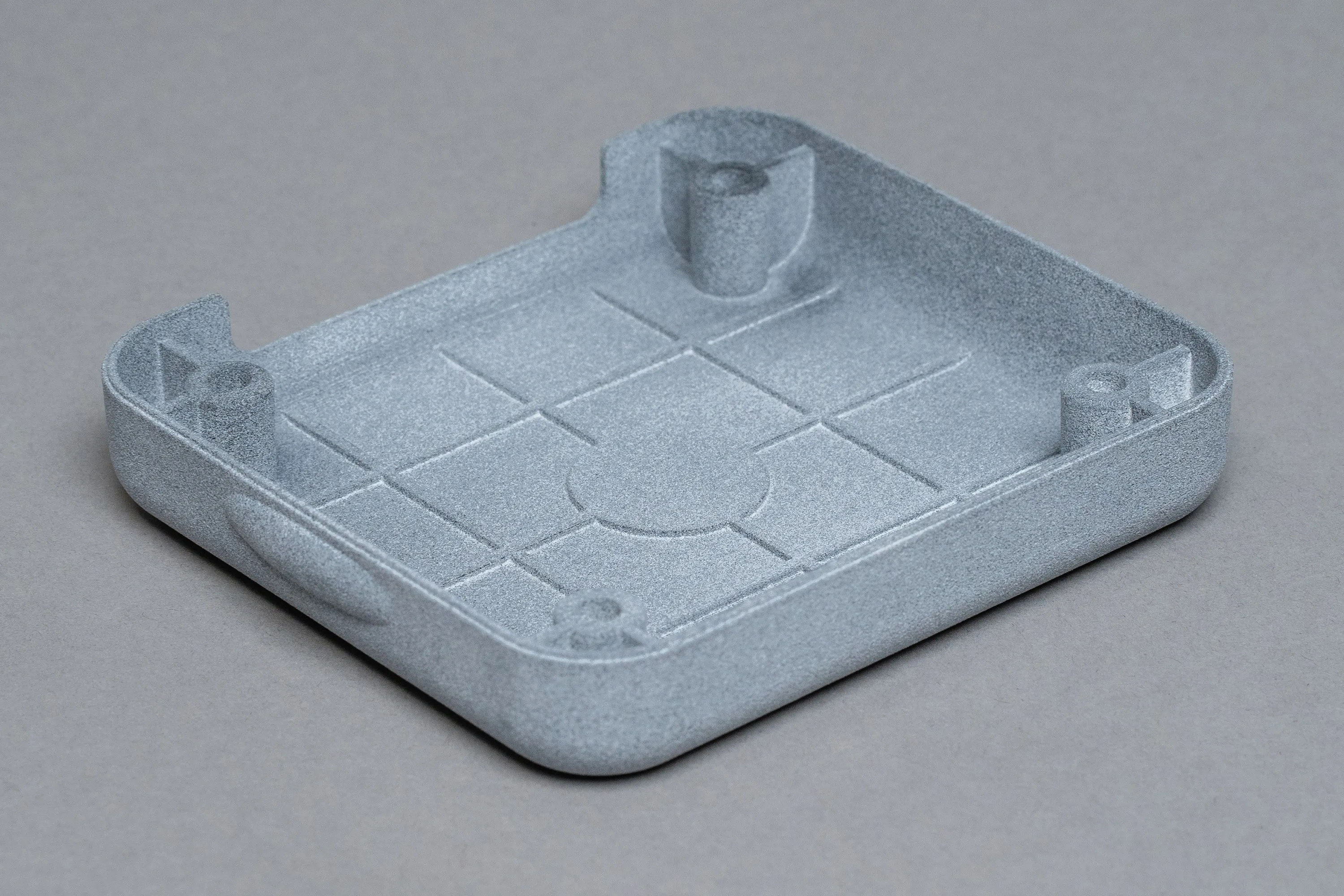

Example of a vapor smoothed dyed black part

Design considerations for vapor smoothing

-

Vapor smoothing can improve the visual appearance of a part or make it more resistant to liquids. If water resistance is required, please specify this before production as it affects the process.

-

Consider how the parts will hang on racks during the process, as hanging marks might be visible on the final result.

-

Whether a part can be vapor smoothed depends on its geometry and wall thickness. Parts with complex geometries, such as sharp corners and edges, and those with thin walls may not be suitable for vapor smoothing.

What is vapor smoothing?

Vapor smoothing is the process of creating an even glossy finish across the outer layer of a part by exposing it to a solvent. The outer layer is melted and cooled in a chamber, giving the finished part aesthetic appeal and functional benefits such as reduced moisture absorption.

Vapor smoothing works by liquifying and redistributing the outer layer of a part using a vaporized solvent. This evens out the part’s surface, reducing the roughness that can occur during 3D printing.

Protolabs Network offers vapor smoothing for 3D printed parts to improve their cosmetic and functional performance. To find out more, contact network-sales@protolabs.com

The vapor smoothing process

-

After 3D printing, the part is cleaned and prepared for vapor smoothing by removing any debris.

-

The part is then sealed in a container with a small amount of solvent, such as acetone or MEK (methyl ethyl ketone).

-

The vapor condenses onto the surface of the part, melting and fusing the outer layer of the printed object.

-

After the desired finish is achieved, the part is removed from the container and allowed to cool and dry.

FAQ's

What materials can be vapor smoothed

Nylon 12, (PA 12), is a robust thermoplastic used for prototypes and end-use applications. It works well with vapor smoothing as long the part’s geometric features are not too intricate.

Can you vapor smooth PLA or ABS?

We currently only offer vapor smoothing for MJF and SLS 3D printing (using PA 12), however, you can discuss custom requests and other recommendations with our team via networksales@protolabs.com.

Do your parts need to be vapor smoothed?

Deciding whether to vapor smooth 3D printed parts depends on their end use. Vapor smoothing evens out the surface of parts, reducing imperfections without adding or subtracting material. The process also helps improve a part’s resistance to liquids.

How do you smooth 3D printed parts?

Vapor smoothing is an effective method of reducing layer lines and texture caused during 3D printing. As an alternative, 3D printed parts can also be smoothed using vibro polishing, available on request by contacting networksales@protolabs.com.

How long does vapor smoothing take?

Several factors affect the time it takes to vapor smooth a part but it is usually completed in a matter of hours.