Some of our vetted manufacturing partners

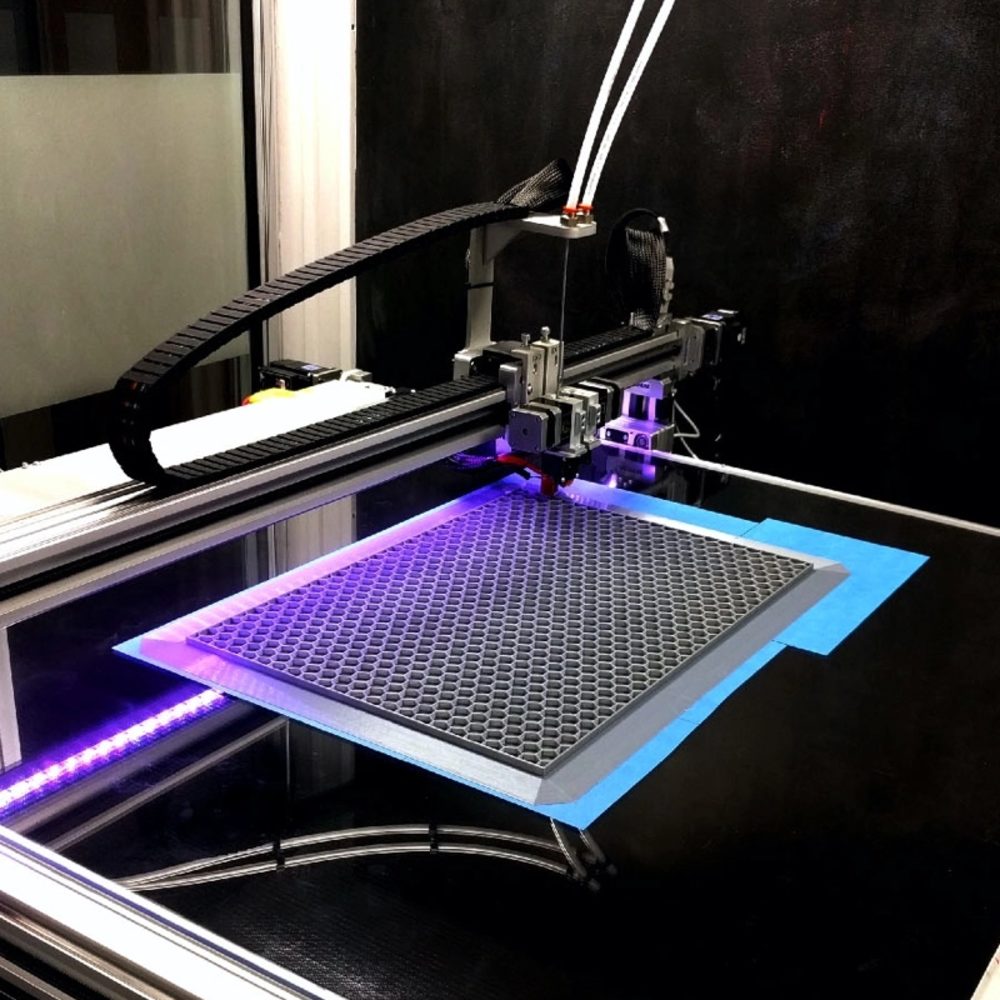

3D printing factory in Texas

|

|

| Established |

2011 |

| Capabilities |

FDM & MJF |

| Machines |

60+ FDM and 3 MJF |

| Expertise |

Fast turnaround prototypes and high quantity final parts. |

| Description |

Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

|

|

| Established |

2018 |

| Capabilities |

MJF & FDM |

| Machines |

2 MJF & 2 FDM machines |

| Expertise |

Large scale FDM & multiple nylon materials using MJF |

| Description |

Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in The Netherlands

|

|

| Established |

2010 |

| Capabilities |

Selective Laser Sintering |

| Machines |

5 EOS Machines |

| Expertise |

Range of SLS Nylons for Food and Medical |

| Description |

Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Chicago

|

|

| Established |

2013 |

| Capabilities |

SLS |

| Machines |

4 EOS Machines |

| Expertise |

Fast prototypes and end parts using SLS Nylon |

| Description |

Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

CNC machining factory in the USA

|

|

| Capabilities |

5-axis machining |

| Machines |

Vertical Mill machines with 5-axis rotary table, Dual axis turning center |

| Description |

High end, 5-axis machine shop with capabilities to produce complex, and some cosmetic, low volume production parts |

CNC machining factory in China

|

|

| Established |

2015 |

| Capabilities |

CNC parts for the medical and consumer products industries |

| Machines |

40 CNC machines, 6 CNC bending presses |

| Expertise |

Visual prototypes and functional end parts |

| Description |

Produce end-product parts with high cosmetic requirements |

CNC machining factory in India

|

|

| Established |

2019 |

| Capabilities |

CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines |

Mazak & Doosan |

| Expertise |

Fast, low-cost prototyping. Strong and complex end-use parts |

| Description |

Specializes in highly complex parts with difficult geometries and tight tolerances |

3D printing factory in Texas

|

|

| Established |

2011 |

| Capabilities |

FDM & MJF |

| Machines |

60+ FDM and 3 MJF |

| Expertise |

Fast turnaround prototypes and high quantity final parts. |

| Description |

Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

|

|

| Established |

2018 |

| Capabilities |

MJF & FDM |

| Machines |

2 MJF & 2 FDM machines |

| Expertise |

Large scale FDM & multiple nylon materials using MJF |

| Description |

Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in The Netherlands

|

|

| Established |

2010 |

| Capabilities |

Selective Laser Sintering |

| Machines |

5 EOS Machines |

| Expertise |

Range of SLS Nylons for Food and Medical |

| Description |

Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Chicago

|

|

| Established |

2013 |

| Capabilities |

SLS |

| Machines |

4 EOS Machines |

| Expertise |

Fast prototypes and end parts using SLS Nylon |

| Description |

Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

CNC machining factory in the USA

|

|

| Capabilities |

5-axis machining |

| Machines |

Vertical Mill machines with 5-axis rotary table, Dual axis turning center |

| Description |

High end, 5-axis machine shop with capabilities to produce complex, and some cosmetic, low volume production parts |

CNC machining factory in China

|

|

| Established |

2015 |

| Capabilities |

CNC parts for the medical and consumer products industries |

| Machines |

40 CNC machines, 6 CNC bending presses |

| Expertise |

Visual prototypes and functional end parts |

| Description |

Produce end-product parts with high cosmetic requirements |

CNC machining factory in India

|

|

| Established |

2019 |

| Capabilities |

CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines |

Mazak & Doosan |

| Expertise |

Fast, low-cost prototyping. Strong and complex end-use parts |

| Description |

Specializes in highly complex parts with difficult geometries and tight tolerances |

3D printing factory in Texas

|

|

| Established |

2011 |

| Capabilities |

FDM & MJF |

| Machines |

60+ FDM and 3 MJF |

| Expertise |

Fast turnaround prototypes and high quantity final parts. |

| Description |

Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

|

|

| Established |

2018 |

| Capabilities |

MJF & FDM |

| Machines |

2 MJF & 2 FDM machines |

| Expertise |

Large scale FDM & multiple nylon materials using MJF |

| Description |

Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in The Netherlands

|

|

| Established |

2010 |

| Capabilities |

Selective Laser Sintering |

| Machines |

5 EOS Machines |

| Expertise |

Range of SLS Nylons for Food and Medical |

| Description |

Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Chicago

|

|

| Established |

2013 |

| Capabilities |

SLS |

| Machines |

4 EOS Machines |

| Expertise |

Fast prototypes and end parts using SLS Nylon |

| Description |

Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

CNC machining factory in the USA

|

|

| Capabilities |

5-axis machining |

| Machines |

Vertical Mill machines with 5-axis rotary table, Dual axis turning center |

| Description |

High end, 5-axis machine shop with capabilities to produce complex, and some cosmetic, low volume production parts |

CNC machining factory in China

|

|

| Established |

2015 |

| Capabilities |

CNC parts for the medical and consumer products industries |

| Machines |

40 CNC machines, 6 CNC bending presses |

| Expertise |

Visual prototypes and functional end parts |

| Description |

Produce end-product parts with high cosmetic requirements |

CNC machining factory in India

|

|

| Established |

2019 |

| Capabilities |

CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines |

Mazak & Doosan |

| Expertise |

Fast, low-cost prototyping. Strong and complex end-use parts |

| Description |

Specializes in highly complex parts with difficult geometries and tight tolerances |

3D printing factory in Texas

|

|

| Established |

2011 |

| Capabilities |

FDM & MJF |

| Machines |

60+ FDM and 3 MJF |

| Expertise |

Fast turnaround prototypes and high quantity final parts. |

| Description |

Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

|

|

| Established |

2018 |

| Capabilities |

MJF & FDM |

| Machines |

2 MJF & 2 FDM machines |

| Expertise |

Large scale FDM & multiple nylon materials using MJF |

| Description |

Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in The Netherlands

|

|

| Established |

2010 |

| Capabilities |

Selective Laser Sintering |

| Machines |

5 EOS Machines |

| Expertise |

Range of SLS Nylons for Food and Medical |

| Description |

Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Chicago

|

|

| Established |

2013 |

| Capabilities |

SLS |

| Machines |

4 EOS Machines |

| Expertise |

Fast prototypes and end parts using SLS Nylon |

| Description |

Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

CNC machining factory in the USA

|

|

| Capabilities |

5-axis machining |

| Machines |

Vertical Mill machines with 5-axis rotary table, Dual axis turning center |

| Description |

High end, 5-axis machine shop with capabilities to produce complex, and some cosmetic, low volume production parts |

CNC machining factory in China

|

|

| Established |

2015 |

| Capabilities |

CNC parts for the medical and consumer products industries |

| Machines |

40 CNC machines, 6 CNC bending presses |

| Expertise |

Visual prototypes and functional end parts |

| Description |

Produce end-product parts with high cosmetic requirements |

CNC machining factory in India

|

|

| Established |

2019 |

| Capabilities |

CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines |

Mazak & Doosan |

| Expertise |

Fast, low-cost prototyping. Strong and complex end-use parts |

| Description |

Specializes in highly complex parts with difficult geometries and tight tolerances |

3D printing factory in Texas

|

|

| Established |

2011 |

| Capabilities |

FDM & MJF |

| Machines |

60+ FDM and 3 MJF |

| Expertise |

Fast turnaround prototypes and high quantity final parts. |

| Description |

Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

|

|

| Established |

2018 |

| Capabilities |

MJF & FDM |

| Machines |

2 MJF & 2 FDM machines |

| Expertise |

Large scale FDM & multiple nylon materials using MJF |

| Description |

Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in The Netherlands

|

|

| Established |

2010 |

| Capabilities |

Selective Laser Sintering |

| Machines |

5 EOS Machines |

| Expertise |

Range of SLS Nylons for Food and Medical |

| Description |

Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Chicago

|

|

| Established |

2013 |

| Capabilities |

SLS |

| Machines |

4 EOS Machines |

| Expertise |

Fast prototypes and end parts using SLS Nylon |

| Description |

Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

CNC machining factory in the USA

|

|

| Capabilities |

5-axis machining |

| Machines |

Vertical Mill machines with 5-axis rotary table, Dual axis turning center |

| Description |

High end, 5-axis machine shop with capabilities to produce complex, and some cosmetic, low volume production parts |

CNC machining factory in China

|

|

| Established |

2015 |

| Capabilities |

CNC parts for the medical and consumer products industries |

| Machines |

40 CNC machines, 6 CNC bending presses |

| Expertise |

Visual prototypes and functional end parts |

| Description |

Produce end-product parts with high cosmetic requirements |

CNC machining factory in India

|

|

| Established |

2019 |

| Capabilities |

CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines |

Mazak & Doosan |

| Expertise |

Fast, low-cost prototyping. Strong and complex end-use parts |

| Description |

Specializes in highly complex parts with difficult geometries and tight tolerances |

3D printing factory in Texas

|

|

| Established |

2011 |

| Capabilities |

FDM & MJF |

| Machines |

60+ FDM and 3 MJF |

| Expertise |

Fast turnaround prototypes and high quantity final parts. |

| Description |

Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

|

|

| Established |

2018 |

| Capabilities |

MJF & FDM |

| Machines |

2 MJF & 2 FDM machines |

| Expertise |

Large scale FDM & multiple nylon materials using MJF |

| Description |

Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in The Netherlands

|

|

| Established |

2010 |

| Capabilities |

Selective Laser Sintering |

| Machines |

5 EOS Machines |

| Expertise |

Range of SLS Nylons for Food and Medical |

| Description |

Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Chicago

|

|

| Established |

2013 |

| Capabilities |

SLS |

| Machines |

4 EOS Machines |

| Expertise |

Fast prototypes and end parts using SLS Nylon |

| Description |

Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

CNC machining factory in the USA

|

|

| Capabilities |

5-axis machining |

| Machines |

Vertical Mill machines with 5-axis rotary table, Dual axis turning center |

| Description |

High end, 5-axis machine shop with capabilities to produce complex, and some cosmetic, low volume production parts |

CNC machining factory in China

|

|

| Established |

2015 |

| Capabilities |

CNC parts for the medical and consumer products industries |

| Machines |

40 CNC machines, 6 CNC bending presses |

| Expertise |

Visual prototypes and functional end parts |

| Description |

Produce end-product parts with high cosmetic requirements |

CNC machining factory in India

|

|

| Established |

2019 |

| Capabilities |

CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines |

Mazak & Doosan |

| Expertise |

Fast, low-cost prototyping. Strong and complex end-use parts |

| Description |

Specializes in highly complex parts with difficult geometries and tight tolerances |

3D printing factory in Texas

|

|

| Established |

2011 |

| Capabilities |

FDM & MJF |

| Machines |

60+ FDM and 3 MJF |

| Expertise |

Fast turnaround prototypes and high quantity final parts. |

| Description |

Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

|

|

| Established |

2018 |

| Capabilities |

MJF & FDM |

| Machines |

2 MJF & 2 FDM machines |

| Expertise |

Large scale FDM & multiple nylon materials using MJF |

| Description |

Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in The Netherlands

|

|

| Established |

2010 |

| Capabilities |

Selective Laser Sintering |

| Machines |

5 EOS Machines |

| Expertise |

Range of SLS Nylons for Food and Medical |

| Description |

Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Chicago

|

|

| Established |

2013 |

| Capabilities |

SLS |

| Machines |

4 EOS Machines |

| Expertise |

Fast prototypes and end parts using SLS Nylon |

| Description |

Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

CNC machining factory in the USA

|

|

| Capabilities |

5-axis machining |

| Machines |

Vertical Mill machines with 5-axis rotary table, Dual axis turning center |

| Description |

High end, 5-axis machine shop with capabilities to produce complex, and some cosmetic, low volume production parts |

CNC machining factory in China

|

|

| Established |

2015 |

| Capabilities |

CNC parts for the medical and consumer products industries |

| Machines |

40 CNC machines, 6 CNC bending presses |

| Expertise |

Visual prototypes and functional end parts |

| Description |

Produce end-product parts with high cosmetic requirements |

CNC machining factory in India

|

|

| Established |

2019 |

| Capabilities |

CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines |

Mazak & Doosan |

| Expertise |

Fast, low-cost prototyping. Strong and complex end-use parts |

| Description |

Specializes in highly complex parts with difficult geometries and tight tolerances |

3D printing factory in Texas

|

|

| Established |

2011 |

| Capabilities |

FDM & MJF |

| Machines |

60+ FDM and 3 MJF |

| Expertise |

Fast turnaround prototypes and high quantity final parts. |

| Description |

Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

|

|

| Established |

2018 |

| Capabilities |

MJF & FDM |

| Machines |

2 MJF & 2 FDM machines |

| Expertise |

Large scale FDM & multiple nylon materials using MJF |

| Description |

Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in The Netherlands

|

|

| Established |

2010 |

| Capabilities |

Selective Laser Sintering |

| Machines |

5 EOS Machines |

| Expertise |

Range of SLS Nylons for Food and Medical |

| Description |

Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Chicago

|

|

| Established |

2013 |

| Capabilities |

SLS |

| Machines |

4 EOS Machines |

| Expertise |

Fast prototypes and end parts using SLS Nylon |

| Description |

Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

CNC machining factory in the USA

|

|

| Capabilities |

5-axis machining |

| Machines |

Vertical Mill machines with 5-axis rotary table, Dual axis turning center |

| Description |

High end, 5-axis machine shop with capabilities to produce complex, and some cosmetic, low volume production parts |

CNC machining factory in China

|

|

| Established |

2015 |

| Capabilities |

CNC parts for the medical and consumer products industries |

| Machines |

40 CNC machines, 6 CNC bending presses |

| Expertise |

Visual prototypes and functional end parts |

| Description |

Produce end-product parts with high cosmetic requirements |

CNC machining factory in India

|

|

| Established |

2019 |

| Capabilities |

CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines |

Mazak & Doosan |

| Expertise |

Fast, low-cost prototyping. Strong and complex end-use parts |

| Description |

Specializes in highly complex parts with difficult geometries and tight tolerances |

3D printing factory in Texas

|

|

| Established |

2011 |

| Capabilities |

FDM & MJF |

| Machines |

60+ FDM and 3 MJF |

| Expertise |

Fast turnaround prototypes and high quantity final parts. |

| Description |

Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

|

|

| Established |

2018 |

| Capabilities |

MJF & FDM |

| Machines |

2 MJF & 2 FDM machines |

| Expertise |

Large scale FDM & multiple nylon materials using MJF |

| Description |

Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in The Netherlands

|

|

| Established |

2010 |

| Capabilities |

Selective Laser Sintering |

| Machines |

5 EOS Machines |

| Expertise |

Range of SLS Nylons for Food and Medical |

| Description |

Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Chicago

|

|

| Established |

2013 |

| Capabilities |

SLS |

| Machines |

4 EOS Machines |

| Expertise |

Fast prototypes and end parts using SLS Nylon |

| Description |

Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

CNC machining factory in the USA

|

|

| Capabilities |

5-axis machining |

| Machines |

Vertical Mill machines with 5-axis rotary table, Dual axis turning center |

| Description |

High end, 5-axis machine shop with capabilities to produce complex, and some cosmetic, low volume production parts |

CNC machining factory in China

|

|

| Established |

2015 |

| Capabilities |

CNC parts for the medical and consumer products industries |

| Machines |

40 CNC machines, 6 CNC bending presses |

| Expertise |

Visual prototypes and functional end parts |

| Description |

Produce end-product parts with high cosmetic requirements |

CNC machining factory in India

|

|

| Established |

2019 |

| Capabilities |

CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines |

Mazak & Doosan |

| Expertise |

Fast, low-cost prototyping. Strong and complex end-use parts |

| Description |

Specializes in highly complex parts with difficult geometries and tight tolerances |

3D printing factory in Texas

|

|

| Established |

2011 |

| Capabilities |

FDM & MJF |

| Machines |

60+ FDM and 3 MJF |

| Expertise |

Fast turnaround prototypes and high quantity final parts. |

| Description |

Specializes in high-quality FDM parts from years of experience |

3D printing factory in the UK

|

|

| Established |

2018 |

| Capabilities |

MJF & FDM |

| Machines |

2 MJF & 2 FDM machines |

| Expertise |

Large scale FDM & multiple nylon materials using MJF |

| Description |

Specializes in MJF Nylon and large parts using Fused Deposition Modeling |

3D printing factory in The Netherlands

|

|

| Established |

2010 |

| Capabilities |

Selective Laser Sintering |

| Machines |

5 EOS Machines |

| Expertise |

Range of SLS Nylons for Food and Medical |

| Description |

Experts in surface finishes, color matching in a wide range of SLS materials. |

3D printing factory in Chicago

|

|

| Established |

2013 |

| Capabilities |

SLS |

| Machines |

4 EOS Machines |

| Expertise |

Fast prototypes and end parts using SLS Nylon |

| Description |

Specializes in fast turnarounds for SLS Nylon parts with a wide range of post-processes. |

CNC machining factory in the USA

|

|

| Capabilities |

5-axis machining |

| Machines |

Vertical Mill machines with 5-axis rotary table, Dual axis turning center |

| Description |

High end, 5-axis machine shop with capabilities to produce complex, and some cosmetic, low volume production parts |

CNC machining factory in China

|

|

| Established |

2015 |

| Capabilities |

CNC parts for the medical and consumer products industries |

| Machines |

40 CNC machines, 6 CNC bending presses |

| Expertise |

Visual prototypes and functional end parts |

| Description |

Produce end-product parts with high cosmetic requirements |

CNC machining factory in India

|

|

| Established |

2019 |

| Capabilities |

CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines |

Mazak & Doosan |

| Expertise |

Fast, low-cost prototyping. Strong and complex end-use parts |

| Description |

Specializes in highly complex parts with difficult geometries and tight tolerances |