Black oxide services

We offer black oxide coating, a conversion coating used on steel, stainless steel and copper. Black oxide is used mainly for the black smooth appearance and for mildly improving corrosion resistance. Black oxide impregnated with oil can provide the highest amount of corrosion resistance.

| Surface preparation | Colors | Applicable materials | Cosmetic availability | Thickness** | Visual appearance |

|---|---|---|---|---|---|

| As machined (Ra 3.2μm / Ra 126μin) | Steel, Stainless Steel, Copper | Steel, Stainless Steel, Copper | No | 0-30μm / 0-1181μin | Smooth black matte |

Example of a black oxide part

Design considerations for black oxide

Masking: Black oxide does not have a significant dimensional impact, therefore masking parts is not necessary.

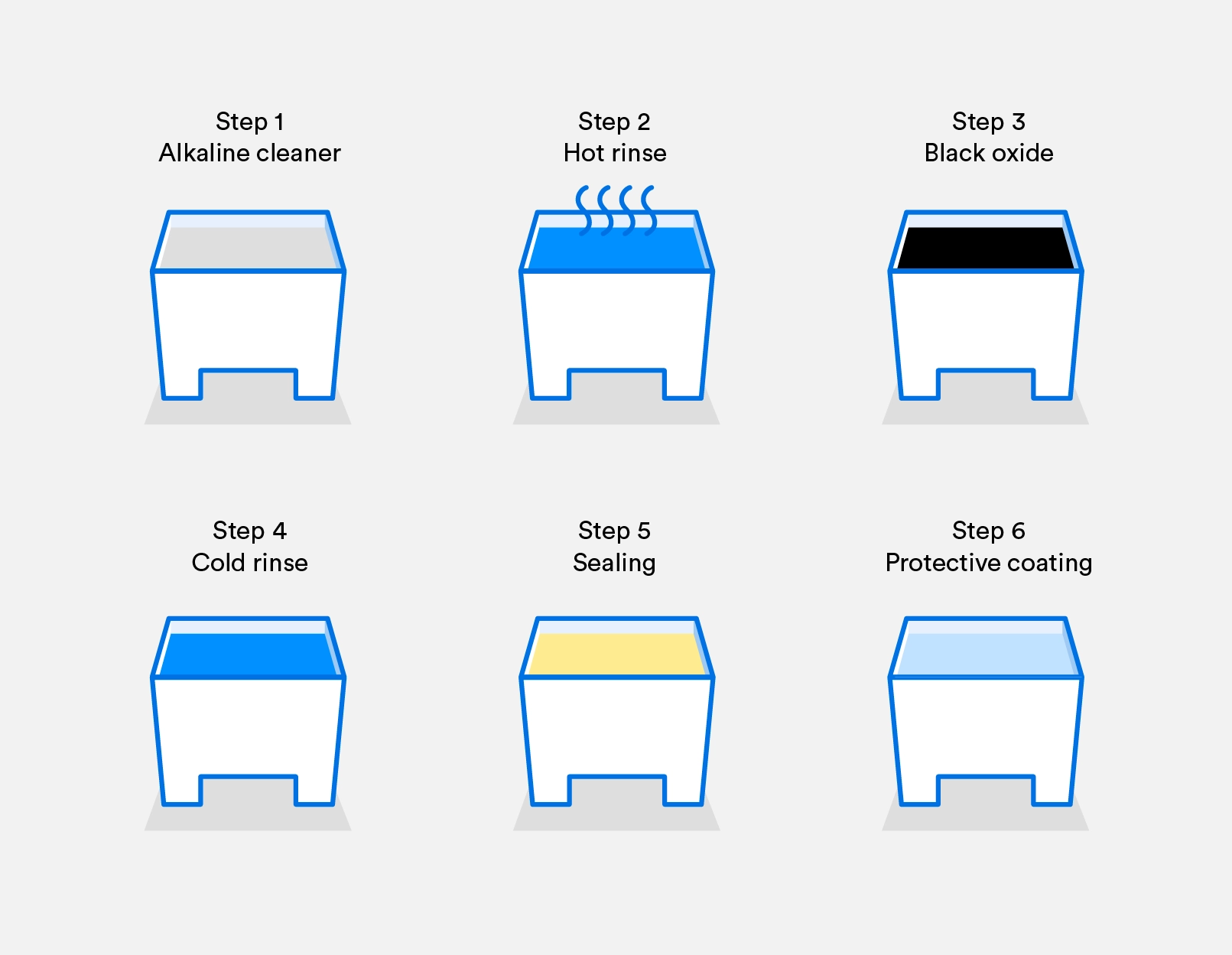

The Protolabs Network black oxide process

Black oxide is a conversion coating, compatible with steel, stainless steel and copper, that provides a black appearance and mildly improves resistance to corrosion of parts.

Here’s how to apply black oxide:

-

First run parts through machining and deburring.

-

Clean parts using alkaline solutions.

-

Rinse in water.

-

Black oxidizing. Immerse the part in the hot (135-145ºC) alkaline bath for a period of 5 to 40 minutes depending on the size of the part

-

Rinse in water.

-

After-finish treatment. Seal the oxide surface with oil, lacquer or wax. This imparts the desired aesthetic appearance and improves the corrosion resistance of the component.

Put your black oxide parts into production today

Get instant quote