About Protolabs Network

If you’re looking for Hubs, you’re in the right place. We have become Protolabs Network to offer you a simplified experience and a single source for your manufacturing needs. Access the boundless capabilities of more than 250 trusted manufacturing partners around the world.

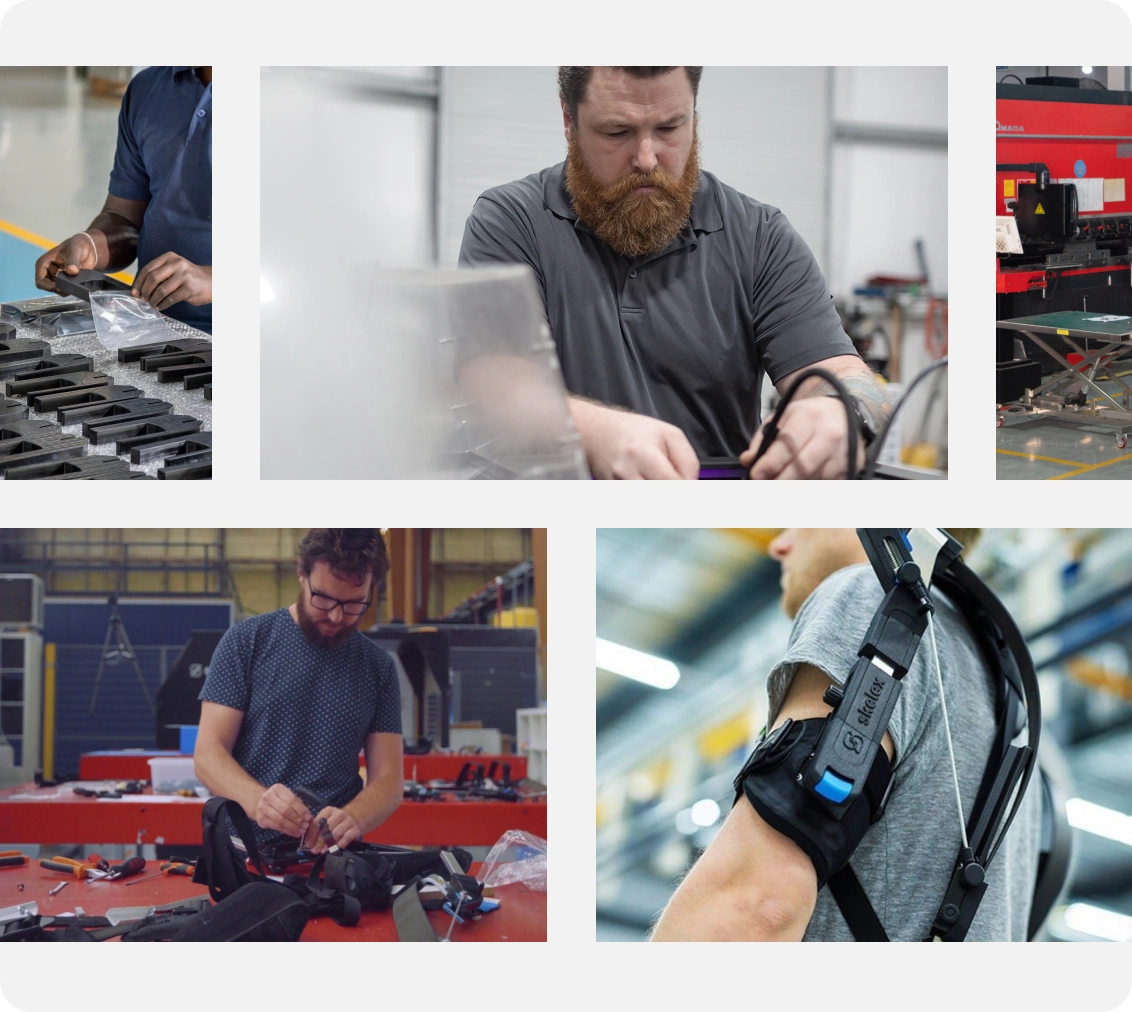

All uploads are secure and confidentialProtolabs’ global network of manufacturing partners

Welcome to the world’s fastest and most comprehensive digital manufacturing solution. We are Protolabs Network, part of Protolabs’ global manufacturing services, and your access point to more than 250 extensively vetted manufacturing partners.

We specialize in 3D printing, CNC machining, injection molding and sheet metal fabrication, offering a wide variety of materials and surface finishes. We have some of the broadest capabilities in the industry, so we can accommodate almost any manufacturing request. When you need parts with intricate geometries, or highly cosmetic finishes, there’s a partner in our network that can produce it.

“Our network of manufacturing partners complements our digital factories, allowing us to provide more complex and larger parts. Now we can better support high-requirement manufacturing projects, and our range of material and finishing options has broadened as well.”

Rob Bodor, President and CEO of Protolabs

How we became Protolabs Network

Protolabs Network started life as the world’s largest peer-to-peer network of 3D printing services, but as we grew with our customers, we needed to offer more.

By expanding our capabilities and enabling production in higher volumes, Protolabs Network became a comprehensive manufacturing solution.

Now that we’re a part of Protolabs, our comprehensive solution helps designers and engineers to get more products to market faster.

A world-first combined solution

By working together, Protolabs and its network bring you one supplier that can manufacture almost any type of custom part, no matter the scope or complexity of your project. Protolabs offers lightning-fast manufacturing with automated in-house machines for quick-turn parts. Protolabs Network expands on this with more capabilities, production capacity and volume pricing. The combination provides engineers with the world’s most comprehensive digital manufacturing solution.

We’re doing what no digital manufacturing model has achieved before–a single point of access to a global manufacturing network in combination with in-house factories for quick-turn parts. It’s a reinvented approach to manufacturing that brings you limitless options throughout your product life cycle. Whether the parts you need require speed or complexity, specific surface finishes or custom tooling, it is our goal to make more options available to designers and engineers.

About Protolabs

Protolabs has been the leader in digital manufacturing since 1999, born from the idea of automating traditional manufacturing processes so that injection molded plastic parts were easier and faster to produce. Now with molding, machining, 3D printing, and sheet metal fabrication capabilities across 12 technology-enabled factories, Protolabs manufactures commercial-grade plastic, metal and liquid silicone parts in as little as 1 day–the fastest lead time in the industry.

Visit Protolabs

Press and media partnerships

Download the Protolabs press kit for high-res images, video and other resources. Visit the Protolabs press page or reach out to press@protolabs.com for more information.

Download the Protolabs press kit

Start your next production project with Protolabs Network

Request a quote