Fast & affordable prototyping

-

Dimensional accuracy of ± 0.5% with a lower limit: ± 0.5 mm

-

Lead times from 1 business day

The easiest way to source high-quality 3D printed prototypes and production parts. Order from our network of highly experienced 3D printing shops. ISO 9001, ISO 13485 and AS9100 certified.

Get an instant 3D printing quote All uploads are secure and confidentialWe have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

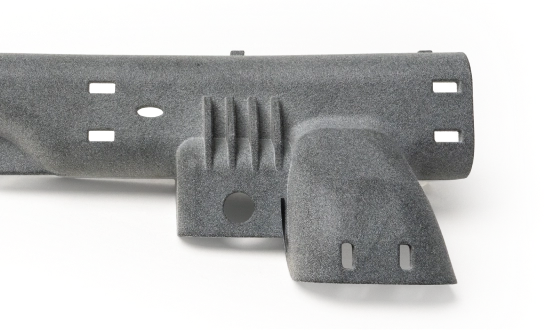

Fast & affordable prototyping

Dimensional accuracy of ± 0.5% with a lower limit: ± 0.5 mm

Lead times from 1 business day

Functional prototyping & low-run production

Dimensional accuracy of ± 0.3% with a lower limit of ± 0.3 mm (± 0.012")

Lead times from 3 business days

Functional prototyping & low-run production

Dimensional accuracy of ± 0.3% with a lower limit of ± 0.3 mm (± 0.012")

Lead times from 3 business days

Visual prototyping

Dimensional accuracy of ± 0.3% with a lower limit of ± 0.3 mm (± 0.012")

Lead times from 2 business days

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to 3D production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

Price updates in real-time as you change materials, lead time, etc..

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Protolabs Network takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets The Protolabs Network Standard.

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

We’ve manufactured millions of parts for all sorts of applications, but we’re especially knowledgeable in these areas.

Aerodynamic parts for aircraft, drones, satellites and rockets with AS 9100 certification.

Read more

Create custom medical devices and diagnostic equipment to get healthcare innovations into hospitals and homes.

Read more

Manufacture parts requiring highly cosmetic features for gaming, audio, video and smart home products.

Produce complex robotic systems, end effectors and automated machinery for this innovative industry.

Read moreWith over 90 local 3D print shops in our network we have virtually unlimited production capacity in both the EU and the US, and can always guarantee broad capabilities, immediate capacity and competitive prices. Our manufacturing partners can offer the following certificates: ISO 9001, ISO 13485 and AS9100.

Protolabs and its network work together to bring you the world's most comprehensive manufacturing solution. While the network can provide a large breadth of capabilities, Protolabs’ factories offer expedited manufacturing with automated in-house machines for the industry's fastest lead times.

Get quick-turn parts with Protolabs

Protolabs Network offers a comprehensive range of additive manufacturing solutions for producing custom parts. From single or smaller quantities of prototypes for rapid product development to intricate and extra durable end-use parts for larger-scale production, our 3D printing services enable you to source parts efficiently without compromising on quality. We offer a huge variety of manufacturing polymers, including PLA, PETG, ABS and Nylon, and our manufacturing partners consistently offer newer and more robust plastics. For metal 3D printing, you can speak with an account manager or explore what Protolabs has to offer. Our 3D printing capabilities make it easier to produce complex end-use components or hold your product in your hands for the very first time, all without having to wait for quotes.

Our network of manufacturing partners brings together highly professional and specialized 3D printing shops. The 3D printing partners we work with are immensely skilled at manufacturing prototypes and production-grade parts using technologies including Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF). This network of experienced and passionate additive manufacturers can produce parts using specialized printers like the Stratasys Fortus line, EOS P390, Markforged Mark 2, HP MJF 5210, 3D Systems Project and Viper line. So no matter what kinds of parts you need, we have access to shops with professional capabilities and limitless capacity.

3D printing technology has developed from a cost-efficient process for rapid prototyping. There are now many bigger, more advanced 3D printers for larger batch sizes of parts and for using materials other than polymers. Technologies like industrial FDM and SLA, SLS and MJF are being used for more industrial purposes, such as higher-volume production and tooling. 3D printing is optimal for creating cheaper molds for injection molding, which overall cuts down the cost of mass-producing plastic parts. Industries like automotive, medical, electrical and even toys use industrial 3D printing technology as a viable alternative to traditional industrial processes like CNC machining and injection molding. With 3D printing, you can accelerate and reduce the cost of industrial-scale production.

Get practical advice on how to design for 3D printing, based upon first-hand experience from the industry’s leading experts. Click here to download the sample chapters.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Protolabs Network provides a comprehensive array of additive manufacturing services catering to diverse applications. Whether you require single prototypes for swift product development or intricate, durable parts for large-scale production, our online 3D printing service assists you in manufacturing components quickly and more cost-effectively. This expedites your innovation cycle, allowing you to concentrate on creating groundbreaking products.

Collaborating with a global network of manufacturing partners, we specialize in four major technologies: Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS) and HP’s Multi Jet Fusion (MJF). Our vetted manufacturing network gives you access to specialized 3D printers such as the Stratasys Fortus line, EOS P390, Markforged Mark 2, HP MJF 5210, 3D Systems Project, and Viper line. This ensures that, regardless of your part requirements, we have access to the ideal technologies for your designs.

We offer a huge variety of manufacturing polymers, including PLA, PETG, ABS and Nylon, and our manufacturing partners consistently offer newer and more robust plastics. For metal 3D printing, you can speak with an account manager or explore what Protolabs has to offer. Our 3D printing capabilities are ideal for intricate end-use components or rapidly developing a product without the need to wait for quotes.

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3D printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet The Protolabs Network Standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Stereolithography (SLA).

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D Printing Handbook.

For tips on designing for production, take a look at our key design considerations for 3D printing. Designing models for 3D printing is generally done with CAD software such as Solidworks and Fusion 360, or 3D modeling software such as Blender, Maya or 3Ds max. To learn more see our article on 3D modeling CAD software.

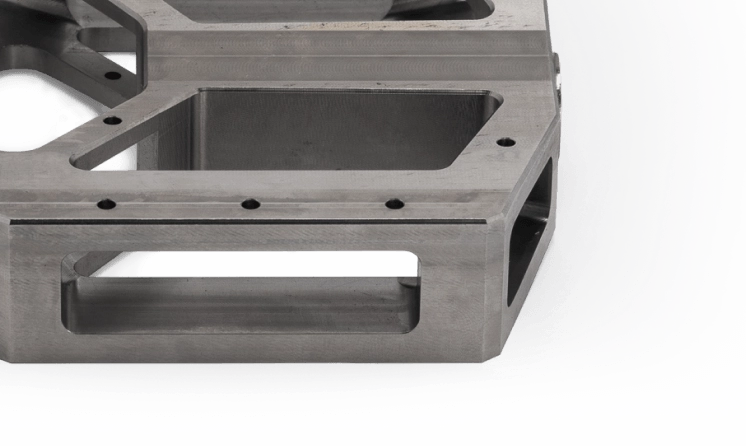

Milling (3-, 4- & full 5-axis), turning and post-processing

50+ metals and plastics & 10 surface finishes

Tolerances down to ±.0008” (0.020 mm)

Lead times from 5 business days

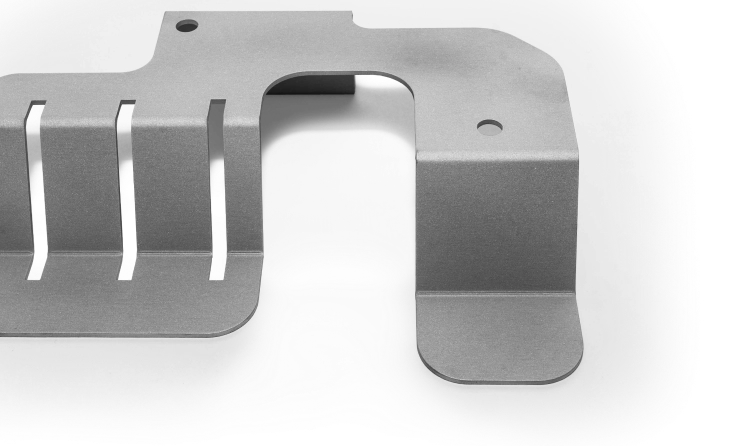

Laser cutting, bending, post-processing

6 metals & 9 surface finishes

Tolerances down to ±.004” (0.010 mm)

Lead times from 5 business days

Prototypes and production tooling

Wide range of part complexities and sizes

1 to 1M parts

Put your 3D printed parts into production today

Get an instant 3D printing quote