CNC milling service

Source custom parts from our network of specialized CNC milling manufacturers. Source custom CNC milling parts using more than 50 different metals and plastics, available in more than 15 surface finishes. Tolerances down to ±.0008"

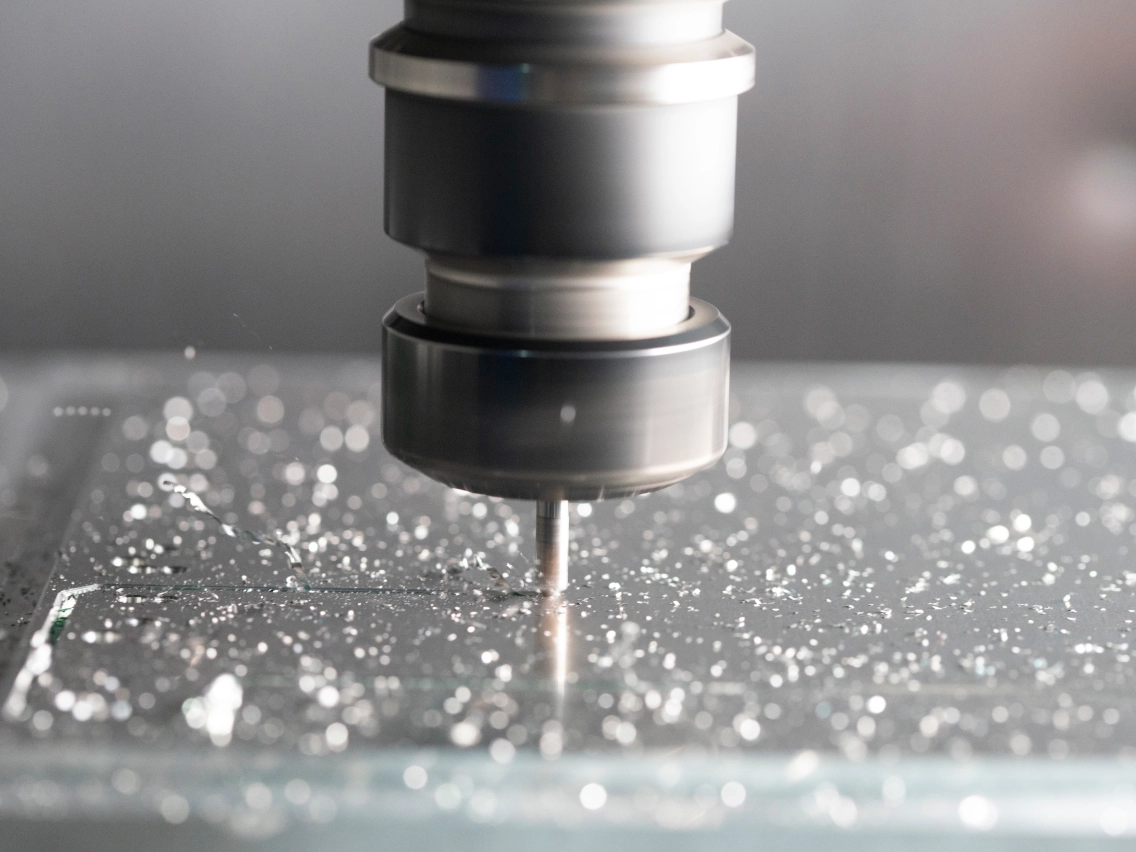

What is CNC milling?

CNC milling uses rotational cutting tools to remove material from a workpiece to produce finished parts and products. This manufacturing process works well for many materials, including metals, polymers, wood and glass. CNC milling systems generally have 3 linear degrees of freedom: the X, Y and Z axis. This allows for top-notch precision and detailing. Protolabs Network also offers more advanced, 5-degree systems, where the tool head and machining bed (A and B axis) can also rotate. 5-axis CNC machines can produce parts with high geometric complexity without needing multiple machine setups.

Learn more about CNC milling and turning

Maximum part size for 3- and 3+2-axis CNC milling

There are several types of CNC milling machines, each with its own distinct maximum part size. 3-axis and 3+2 axis machines have the lowest start-up costs and can produce parts with relatively simple geometries.

3-axis milling

| Size | Metric units | Imperial units |

|---|---|---|

| Max. part size for soft metals [1] & plastics | 2000 x 1500 x 200 mm 1500 x 800 x 500 mm | 78.7 x 59.0 x 7.8 in 59.0 x 31.4 x 27.5 in |

| Max. part for hard metals [2] | 1200 x 800 x 500 mm | 47.2 x 31.4 x 19.6 in |

| Min. feature size | Ø 0.50 mm | Ø 0.019 in |

| [1] : Aluminum, copper & brass [2] : Stainless steel, tool steel, alloy steel & mild steel |

3+2 axis milling

| Size | Metric units | Imperial units |

|---|---|---|

| Max. part size for soft metals [1] & plastics | 2000 x 1500 x 200 mm | 78.7 x 59.0 x 7.8 in |

| Max. part for hard metals [2] | 1200 x 800 x 500 mm | 47.2 x 31.4 x 19.6 in |

| Min. feature size | Ø 0.50 mm | Ø 0.019 in |

| [1] Aluminum, copper & brass [2] Stainless steel, tool steel, alloy steel & mild steel |

Maximum part size for 5-axis CNC milling

The more advanced of the milling machine family, 5-axis centers can produce parts with more complex geometries. These machines require fewer machine setups so they are more productive.

| Size | Metric units | Imperial units |

|---|---|---|

| Max. part size for all materials | 2000 x 1500 x 200 mm | 78.7 x 59.0 x 7.8 in |

| Min. feature size | Ø 0.50 mm | Ø 0.019 in |

Available materials for CNC milling

A wide range of metals for CNC machining, with applications in multiple industries. Ideal for both one-off prototypes and end-use custom parts.

A wide range of plastics for CNC machining, with applications in multiple industries. Ideal for both one-off prototypes and end-use custom parts.

CNC milling surface finishes

Improve your part’s performance by selecting high-quality surface finishes that enhance the roughness, hardness, chemical resistance and cosmetic features of your finished component.

Browse CNC milling surface finishes

CNC milling tolerances

We follow ISO 2768 standards for CNC machining.

| Limits for nominal size | Plastics (ISO 2768- m) | Metals (ISO 2768- f) |

|---|---|---|

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.1mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.2mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.3mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.5mm |

| Over 2000mm to 4000mm | ±2mm | |

| *Please clearly indicate tolerances for nominal sizes below 0.5mm on your technical drawing. |

CNC milling design guidelines

Check the recommended and technically feasible values for the most common features encountered in CNC machined parts.

Learn more in our engineering guide to CNC machining

| Feature | Recommended size | Feasible size |

|---|---|---|

| Min. feature size | Ø 2.5 mm | Ø 0.50 mm |

| Internal edges | R 8 mm | R 0.25 mm |

| Minimum wall thickness | 0.8 mm (for metals) 1.5 mm (for plastics) | 0.5 mm (for metals) 1.0 mm (for plastics) |

| Holes | Diameter: standard drill bit sizes Depth: 4 x diameter |

Diameter: Ø 0.5 Depth: 10 x diameter |

| Threads | Size: M6 or larger Length: 3 x diameter | Size: M2 |

Why should you choose CNC milling?

We have high standards for CNC milling

We manufacture your custom parts according to strict manufacturing standards and ensure all parts and processes adhere to The Protolabs Network Standard.

-

Several surface finishes are available to improve the cosmetic quality of your parts after machining.

-

Every custom part gets checked on site by our manufacturing partners according to our guidelines.

-

Inspection reports and other types of quality documentation are available on request to assure the highest quality and compliance.

More resources for CNC milling

Learn more about how CNC milling works and how to design parts to get the most out this machining process.