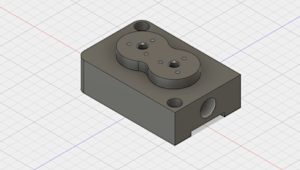

Custom tooling can quickly increase your manufacturing costs. Knowing how to get the most out of standard tooling can save you a significant amount of money on producing custom parts.

To reduce the need for custom tooling, we have created these three tables to summarize the standard drill bit sizes used in CNC machining.

Drill bit size charts

The three tables below provide standard, fractional inch and wire gauge drill bit sizes. It's helpful, and often essential, to match these standard sizes when designing CNC parts with drill holes.

If you design holes that don't fit into these ranges, you may need specialized tooling to manufacture your parts.

Want to learn more about CNC machining?

Standard metric drill bit sizes

| Drill size | Diameter (in) |

|---|---|

| 0.05 mm | 0.0020 |

| 0.1 mm | 0.0039 |

| 0.2 mm | 0.0079 |

| 0.3 mm | 0.0118 |

| 0.4 mm | 0.0158 |

| 0.5 mm | 0.0197 |

| 0.6 mm | 0.0236 |

| 0.7 mm | 0.0276 |

| 0.8 mm | 0.0315 |

| 0.9 mm | 0.0354 |

| 1 mm | 0.0394 |

| 1.1 mm | 0.0433 |

| 1.2 mm | 0.0472 |

| 1.3 mm | 0.0512 |

| 1.4 mm | 0.0551 |

| 1.5 mm | 0.0591 |

| 1.6 mm | 0.0630 |

| 1.7 mm | 0.0669 |

| 1.8 mm | 0.0709 |

| 1.9 mm | 0.0748 |

| 2 mm | 0.0787 |

| 2.1 mm | 0.0827 |

| 2.2 mm | 0.0866 |

| 2.3 mm | 0.0906 |

| 2.4 mm | 0.0945 |

| 2.5 mm | 0.0984 |

| 2.6 mm | 0.1024 |

| 2.7 mm | 0.1063 |

| 2.8 mm | 0.1102 |

| 2.9 mm | 0.1142 |

| 3 mm | 0.1181 |

| 3.1 mm | 0.1221 |

| 3.2 mm | 0.1260 |

| 3.3 mm | 0.1299 |

| 3.4 mm | 0.1339 |

| 3.5 mm | 0.1378 |

| 3.6 mm | 0.1417 |

| 3.7 mm | 0.1457 |

| 3.8 mm | 0.1496 |

| 3.9 mm | 0.1535 |

| 4 mm | 0.1575 |

| 4.1 mm | 0.1614 |

| 4.2 mm | 0.1654 |

| 4.3 mm | 0.1693 |

| 4.4 mm | 0.1732 |

| 4.5 mm | 0.1772 |

| 4.6 mm | 0.1811 |

| 4.7 mm | 0.1850 |

| 4.8 mm | 0.1890 |

| 4.9 mm | 0.1929 |

| 5 mm | 0.1969 |

| 5.1 mm | 0.2008 |

| 5.2 mm | 0.2047 |

| 5.3 mm | 0.2087 |

| 5.4 mm | 0.2126 |

| 5.5 mm | 0.2165 |

| 5.6 mm | 0.2205 |

| 5.7 mm | 0.2244 |

| 5.8 mm | 0.2284 |

| 5.9 mm | 0.2323 |

| 6 mm | 0.2362 |

| 6.1 mm | 0.2402 |

| 6.2 mm | 0.2441 |

| 6.3 mm | 0.2480 |

| 6.4 mm | 0.2520 |

| 6.5 mm | 0.2559 |

| 6.6 mm | 0.2598 |

| 6.7 mm | 0.2638 |

| 6.8 mm | 0.2677 |

| 6.9 mm | 0.2717 |

| 7 mm | 0.2756 |

| 7.1 mm | 0.2795 |

| 7.2 mm | 0.2835 |

| 7.3 mm | 0.2874 |

| 7.4 mm | 0.2913 |

| 7.5 mm | 0.2953 |

| 7.6 mm | 0.2992 |

| 7.7 mm | 0.3032 |

| 7.8 mm | 0.3071 |

| 7.9 mm | 0.3110 |

| 8 mm | 0.3150 |

| 8.1 mm | 0.3189 |

| 8.2 mm | 0.3228 |

| 8.3 mm | 0.3268 |

| 8.4 mm | 0.3307 |

| 8.5 mm | 0.3347 |

| 8.6 mm | 0.3386 |

| 8.7 mm | 0.3425 |

| 8.8 mm | 0.3465 |

| 8.9 mm | 0.3504 |

| 9 mm | 0.3543 |

| 9.1 mm | 0.3583 |

| 9.2 mm | 0.3622 |

| 9.3 mm | 0.3661 |

| 9.4 mm | 0.3701 |

| 9.5 mm | 0.3740 |

| 9.6 mm | 0.3780 |

| 9.7 mm | 0.3819 |

| 9.8 mm | 0.3858 |

| 9.9 mm | 0.3898 |

| 10 mm | 0.3937 |

| 10.5 mm | 0.4134 |

| 11 mm | 0.4331 |

| 11.5 mm | 0.4528 |

| 12 mm | 0.4724 |

| 12.5 mm | 0.4921 |

| 13 mm | 0.5118 |

| 13.5 mm | 0.5315 |

| 14 mm | 0.5512 |

| 14.5 mm | 0.5709 |

| 15 mm | 0.5906 |

| 15.5 mm | 0.6102 |

| 16 mm | 0.6299 |

| 16.5 mm | 0.6496 |

| 17 mm | 0.6693 |

| 17.5 mm | 0.6890 |

| 18 mm | 0.7087 |

| 18.5 mm | 0.7284 |

| 19 mm | 0.7480 |

| 19.5 mm | 0.7677 |

| 20 mm | 0.7874 |

| 20.5 mm | 0.8071 |

| 21 mm | 0.8268 |

| 21.5 mm | 0.8465 |

| 22 mm | 0.8661 |

| 22.5 mm | 0.8858 |

| 23 mm | 0.9055 |

| 23.5 mm | 0.9252 |

| 24 mm | 0.9449 |

| 24.5 mm | 0.9646 |

| 25 mm | 0.9843 |

| 25.5 mm | 1.0039 |

| 26 mm | 1.0236 |

| 26.5 mm | 1.0433 |

| 27 mm | 1.0630 |

| 27.5 mm | 1.0827 |

| 28 mm | 1.1024 |

| 28.5 mm | 1.1221 |

| 29 mm | 1.1417 |

| 29.5 mm | 1.1614 |

| 30 mm | 1.1811 |

| 30.5 mm | 1.2008 |

| 31 mm | 1.2205 |

| 31.5 mm | 1.2402 |

| 32 mm | 1.2598 |

| 32.5 mm | 1.2795 |

| 33 mm | 1.2992 |

| 33.5 mm | 1.3189 |

| 34 mm | 1.3386 |

| 34.5 mm | 1.3583 |

| 35 mm | 1.3780 |

| 35.5 mm | 1.3976 |

| 36 mm | 1.4173 |

| 36.5 mm | 1.4370 |

| 37 mm | 1.4567 |

| 37.5 mm | 1.4764 |

| 38 mm | 1.4961 |

Want to learn more about CNC machining?

Fractional inch drill bit sizes

| Drill size | Diameter (in) | Diameter (mm) |

|---|---|---|

| 1/64 in | 0.0156 | 0.3969 |

| 1/32 in | 0.0313 | 0.7938 |

| 3/64 in | 0.0469 | 1.1906 |

| 1/16 in | 0.0625 | 1.5875 |

| 5/64 in | 0.0781 | 1.9844 |

| 3/32 in | 0.0938 | 2.3813 |

| 7/64 in | 0.1094 | 2.7781 |

| 1/8 in | 0.1250 | 3.1750 |

| 9/64 in | 0.1406 | 3.5719 |

| 5/32 in | 0.1563 | 3.9688 |

| 11/64 in | 0.1719 | 4.3656 |

| 3/16 in | 0.1875 | 4.7625 |

| 13/64 in | 0.2031 | 5.1594 |

| 7/32 in | 0.2188 | 5.5563 |

| 15/64 in | 0.2344 | 5.9531 |

| 1/4 in | 0.2500 | 6.3500 |

| 17/64 in | 0.2656 | 6.7469 |

| 9/32 in | 0.2813 | 7.1438 |

| 19/64 in | 0.2969 | 7.5406 |

| 5/16 in | 0.3125 | 7.9375 |

| 21/64 in | 0.3281 | 8.3344 |

| 11/32 in | 0.3438 | 8.7313 |

| 23/64 in | 0.3594 | 9.1281 |

| 3/8 in | 0.3750 | 9.5250 |

| 25/64 in | 0.3906 | 9.9219 |

| 13/32 in | 0.4063 | 10.3188 |

| 27/64 in | 0.4219 | 10.7156 |

| 7/16 in | 0.4375 | 11.1125 |

| 29/64 in | 0.4531 | 11.5094 |

| 15/32 in | 0.4688 | 11.9063 |

| 31/64 in | 0.4844 | 12.3031 |

| 1/2 in | 0.5000 | 12.7000 |

| 33/64 in | 0.5156 | 13.0969 |

| 17/32 in | 0.5313 | 13.4938 |

| 35/64 in | 0.5469 | 13.8906 |

| 9/16 in | 0.5625 | 14.2875 |

| 37/64 in | 0.5781 | 14.6844 |

| 19/32 in | 0.5938 | 15.0813 |

| 39/64 in | 0.6094 | 15.4781 |

| 5/8 in | 0.6250 | 15.8750 |

| 41/64 in | 0.6406 | 16.2719 |

| 43/64 in | 0.6719 | 17.0656 |

| 11/16 in | 0.6875 | 17.4625 |

| 45/64 in | 0.7031 | 17.8594 |

| 23/32 in | 0.7188 | 18.2563 |

| 47/64 in | 0.7344 | 18.6531 |

| 3/4 in | 0.7500 | 19.0500 |

| 49/64 in | 0.7656 | 19.4469 |

| 25/32 in | 0.7813 | 19.8438 |

| 51/64 in | 0.7969 | 20.2406 |

| 13/16 in | 0.8125 | 20.6375 |

| 53/64 in | 0.8281 | 21.0344 |

| 27/32 in | 0.8438 | 21.4313 |

| 55/64 in | 0.8594 | 21.8281 |

| 7/8 in | 0.8750 | 22.2250 |

| 57/64 in | 0.8906 | 22.6219 |

| 29/32 in | 0.9063 | 23.0188 |

| 21/23 in | 0.9130 | 23.1913 |

| 59/64 in | 0.9219 | 23.4156 |

| 15/16 in | 0.9375 | 23.8125 |

| 61/64 in | 0.9531 | 24.2094 |

| 31/32 in | 0.9688 | 24.6063 |

| 63/64 in | 0.9844 | 25.0031 |

| 1 in | 1.0000 | 25.4000 |

| 1 1/64 in | 1.0156 | 25.7969 |

| 1 1/32 in | 1.0313 | 26.1938 |

| 1 3/64 in | 1.0469 | 26.5906 |

| 1 1/16 in | 1.0625 | 26.9875 |

| 1 5/64 in | 1.0781 | 27.3844 |

| 1 3/32 in | 1.0938 | 27.7813 |

| 1 7/64 in | 1.1094 | 28.1781 |

| 1 1/8 in | 1.1250 | 28.5750 |

| 1 9/64 in | 1.1406 | 28.9719 |

| 1 5/32 in | 1.1563 | 29.3688 |

| 1 11/64 in | 1.1719 | 29.7656 |

| 1 3/16 in | 1.1875 | 30.1625 |

| 1 13/64 in | 1.2031 | 30.5594 |

| 1 7/32 in | 1.2188 | 30.9563 |

| 1 15/64 in | 1.2344 | 31.3531 |

| 1 1/4 in | 1.2500 | 31.7500 |

| 1 17/64 in | 1.2656 | 32.1469 |

| 1 9/32 in | 1.2813 | 32.5438 |

| 1 19/64 in | 1.2969 | 32.9406 |

| 1 5/16 in | 1.3125 | 33.3375 |

| 1 21/64 in | 1.3281 | 33.7344 |

| 1 11/32 in | 1.3438 | 34.1313 |

| 1 23/64 in | 1.3594 | 34.5281 |

| 1 3/8 in | 1.3750 | 34.9250 |

| 1 25/64 in | 1.3906 | 35.3219 |

| 1 13/32 in | 1.4063 | 35.7188 |

| 1 27/64 in | 1.4219 | 36.1156 |

| 1 7/16 in | 1.4375 | 36.5125 |

| 1 29/64 in | 1.4531 | 36.9094 |

| 1 15/32 in | 1.4688 | 37.3063 |

| 1 31/64 in | 1.4844 | 37.7031 |

| 1 1/2 in | 1.5000 | 38.1000 |

Ready to produce complex, custom parts for your project?

Wire gauge drill bit sizes

| Drill size | Diameter (in) | Diameter (mm) |

|---|---|---|

| #107 | 0.0019 | 0.0483 |

| #106 | 0.0023 | 0.0584 |

| #105 | 0.0027 | 0.0686 |

| #104 | 0.0031 | 0.0787 |

| #103 | 0.0035 | 0.0889 |

| #102 | 0.0039 | 0.0991 |

| #101 | 0.0043 | 0.1092 |

| #100 | 0.0047 | 0.1194 |

| #99 | 0.0051 | 0.1295 |

| #98 | 0.0055 | 0.1397 |

| #97 | 0.0059 | 0.1499 |

| #96 | 0.0063 | 0.1600 |

| #95 | 0.0067 | 0.1702 |

| #94 | 0.0071 | 0.1803 |

| #93 | 0.0075 | 0.1905 |

| #92 | 0.0079 | 0.2007 |

| #91 | 0.0083 | 0.2108 |

| #90 | 0.0087 | 0.2210 |

| #89 | 0.0091 | 0.2311 |

| #88 | 0.0095 | 0.2413 |

| #87 | 0.0100 | 0.2540 |

| #86 | 0.0105 | 0.2667 |

| #85 | 0.0110 | 0.2794 |

| #84 | 0.0115 | 0.2921 |

| #83 | 0.0120 | 0.3048 |

| #82 | 0.0125 | 0.3175 |

| #81 | 0.0130 | 0.3302 |

| #80 | 0.0135 | 0.3429 |

| #79 | 0.0145 | 0.3680 |

| #78 | 0.0160 | 0.4064 |

| #77 | 0.0180 | 0.4572 |

| #76 | 0.0200 | 0.5080 |

| #75 | 0.0210 | 0.5334 |

| #74 | 0.0225 | 0.5715 |

| #73 | 0.0240 | 0.6096 |

| #72 | 0.0250 | 0.6350 |

| #71 | 0.0260 | 0.6604 |

| #70 | 0.0280 | 0.7112 |

| #69 | 0.0292 | 0.7417 |

| #68 | 0.0310 | 0.7874 |

| #67 | 0.0320 | 0.8128 |

| #66 | 0.0330 | 0.8382 |

| #65 | 0.0350 | 0.8890 |

| #64 | 0.0360 | 0.9144 |

| #63 | 0.0370 | 0.9398 |

| #62 | 0.0380 | 0.9652 |

| #61 | 0.0390 | 0.9906 |

| #60 | 0.0400 | 1.0160 |

| #59 | 0.0410 | 1.0414 |

| #58 | 0.0420 | 1.0668 |

| #57 | 0.0430 | 1.0922 |

| #56 | 0.0465 | 1.1811 |

| #55 | 0.0520 | 1.3208 |

| #54 | 0.0550 | 1.3970 |

| #53 | 0.0595 | 1.5113 |

| #52 | 0.0635 | 1.6129 |

| #51 | 0.0670 | 1.7018 |

| #50 | 0.0700 | 1.7780 |

| #49 | 0.0730 | 1.8542 |

| #48 | 0.0760 | 1.9304 |

| #47 | 0.0785 | 1.9939 |

| #46 | 0.0810 | 2.0574 |

| #45 | 0.0820 | 2.0828 |

| #44 | 0.0860 | 2.1844 |

| #43 | 0.0890 | 2.2606 |

| #42 | 0.0935 | 2.3749 |

| #41 | 0.0960 | 2.4384 |

| #40 | 0.0980 | 2.4892 |

| #39 | 0.0995 | 2.5273 |

| #38 | 0.1015 | 2.5781 |

| #37 | 0.1040 | 2.6416 |

| #36 | 0.1065 | 2.7051 |

| #35 | 0.1100 | 2.7940 |

| #34 | 0.1110 | 2.8194 |

| #33 | 0.1130 | 2.8702 |

| #32 | 0.1160 | 2.9464 |

| #31 | 0.1200 | 3.0480 |

| #30 | 0.1285 | 3.2639 |

| #29 | 0.1360 | 3.4544 |

| #28 | 0.1405 | 3.5687 |

| #27 | 0.1440 | 3.6576 |

| #26 | 0.1470 | 3.7338 |

| #25 | 0.1495 | 3.7973 |

| #24 | 0.1520 | 3.8608 |

| #23 | 0.1540 | 3.9116 |

| #22 | 0.1570 | 3.9878 |

| #21 | 0.1590 | 4.0386 |

| #20 | 0.1610 | 4.0894 |

| #19 | 0.1660 | 4.2164 |

| #18 | 0.1695 | 4.3053 |

| #17 | 0.1730 | 4.3942 |

| #16 | 0.1770 | 4.4958 |

| #15 | 0.1800 | 4.5720 |

| #14 | 0.1820 | 4.6228 |

| #13 | 0.1850 | 4.6990 |

| #12 | 0.1890 | 4.8006 |

| #11 | 0.1910 | 4.8514 |

| #10 | 0.1935 | 4.9149 |

| #9 | 0.1960 | 4.9784 |

| #8 | 0.1990 | 5.0546 |

| #7 | 0.2010 | 5.1054 |

| #6 | 0.2040 | 5.1816 |

| #5 | 0.2055 | 5.2197 |

| #4 | 0.2090 | 5.3086 |

| #3 | 0.2130 | 5.4102 |

| #2 | 0.2210 | 5.6134 |

| #1 | 0.2280 | 5.7912 |

| A | 0.2340 | 5.9436 |

| B | 0.2380 | 6.0452 |

| C | 0.2420 | 6.1468 |

| D | 0.2460 | 6.2484 |

| E | 0.2500 | 6.3500 |

| F | 0.2570 | 6.5278 |

| G | 0.2610 | 6.6294 |

| H | 0.2660 | 6.7564 |

| I | 0.2720 | 6.9088 |

| J | 0.2770 | 7.0358 |

| K | 0.2810 | 7.1374 |

| L | 0.2900 | 7.3660 |

| M | 0.2950 | 7.4930 |

| N | 0.3020 | 7.6708 |

| O | 0.3160 | 8.0264 |

| P | 0.3230 | 8.2042 |

| Q | 0.3320 | 8.4328 |

| R | 0.3390 | 8.6106 |

| S | 0.3480 | 8.8392 |

| T | 0.3580 | 9.0932 |

| U | 0.3680 | 9.3472 |

| V | 0.3770 | 9.5758 |

| W | 0.3860 | 9.8044 |

| X | 0.3970 | 10.0838 |

| Y | 0.4040 | 10.2616 |

| Z | 0.4130 | 10.4902 |

Learn how to cut CNC machining costs by 50%