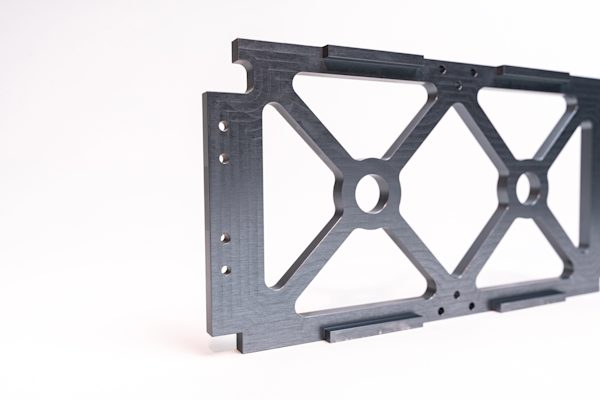

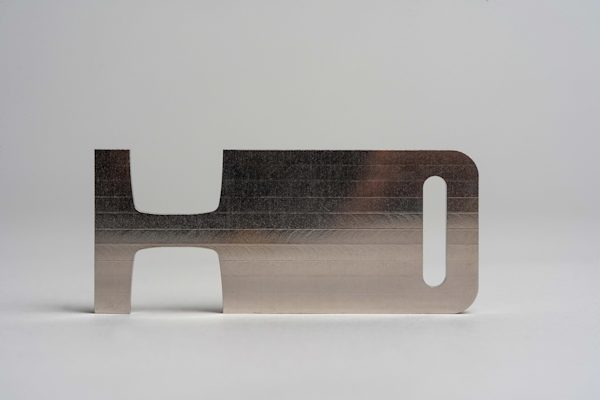

Post-processes & finishes

Material choice, post-processing and surface finishing can make all the difference in manufacturing. Processes like cleaning, curing, polishing and dyeing improve the cosmetic and functional qualities of 3D printed parts. And for CNC machining, anodizing, powder coating and electroless nickel plating impact a part's appearance, strength, electrical conductivity and more. Find out more about the various materials used in manufacturing and explore how post-processing and surface finishing work.