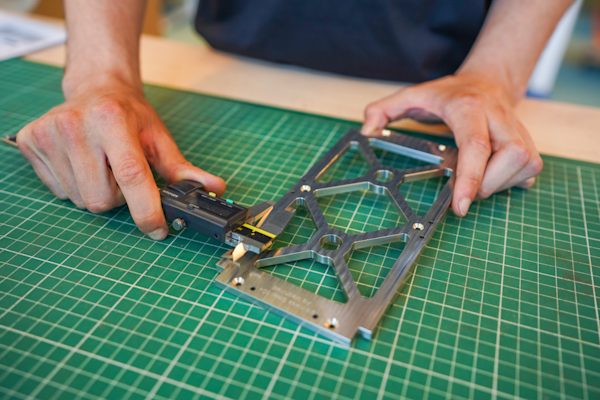

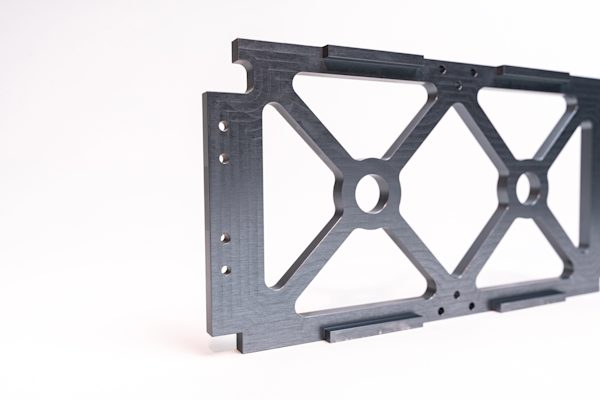

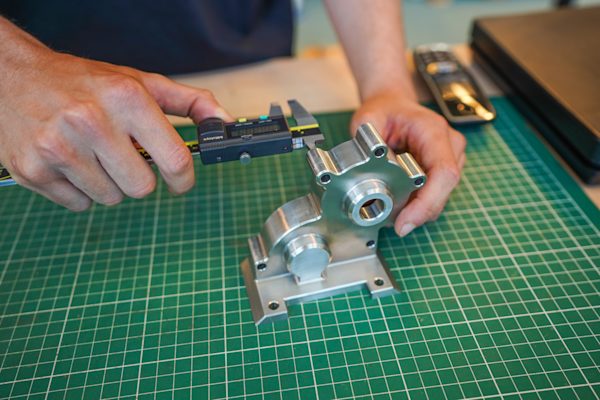

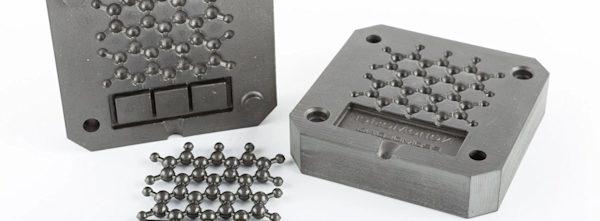

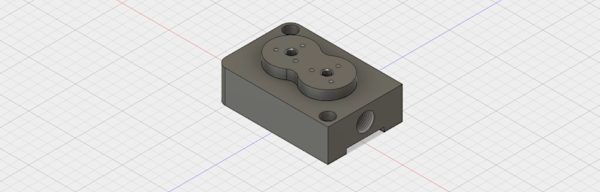

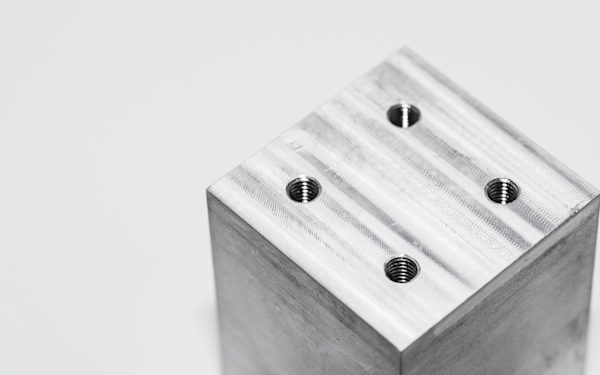

Design for CNC machining

CNC (computer numerically controlled) machining is a robust and high-precision process for manufacturing custom parts. Optimizing the way you design parts can help you get more out CNC's range of milling and turning solutions. This section provides design guidance for reducing costs, speeding up machining times and ensuring parts get produced to your specifications. Learn how to design parts to get the most out of CNC.