Injection molding

How does injection molding work and when is it the right time to start using it to manufacturing your parts? Level up your knowledge in this versatile and robust technology, the characteristics that give it its powerful repeatability and how to design parts to get the most out of injection molding.

What are the common applications of injection molding and its top benefits?

What are the common applications of injection molding? What sets it apart as a manufacturing process? This article covers the key benefits of injection molding and provides insight into whether injection molding is right for your industry’s applications.

How to avoid common defects in injection molding

What are the most common defects in the injection molding process and how do you avoid them? This article provides six essential design tips for avoid production defects while reducing the cost and lead time of your molded parts.

What is Delrin (POM-H) and what are its material properties?

What is Delrin and why is it unique among the many manufacturing materials available? Delrin, or POM-H (homopolymer acetal), is used in CNC machining, 3D printing and injection molding to create durable, precise components. This article explores Delrin’s properties and how to get the most out of the material.

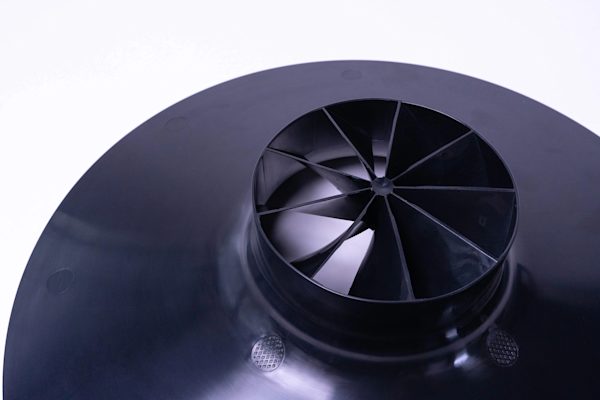

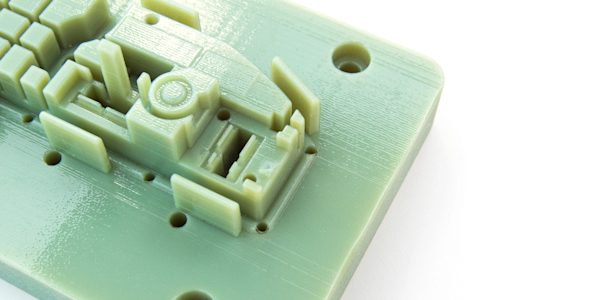

3D printing low-run injection molds

This article discusses the use of 3D printing to print molds for low run injection molding. Design considerations, materials, molds configurations and a comparative case study are all included

What’s the best SPI surface finish for your injection molded part?

What SPI surface finishes does Protolabs Network have for injection molding custom parts? Check out the standard SPI mold finishes we offer and our material recommendations to get the most out of injection molding.

How much does injection molding cost?

In this article, we’ll take a look at common factors that influence the cost of injection molding, including equipment, labor, and materials – as well as tips for reducing manufacturing costs.

How do you design parts for injection molding?

How do you optimize part design for injection molding? This complete guide to designing for injection molding provides basic and advanced design tips, including guidelines for creating snap-fits, living hinges and undercuts, and accounting for optimial surface finishes.

What is injection molding?

What is injection molding and how does it work? In this comprehensive introduction, we cover the basic principles of this efficient and repeatable manufacturing technology. After reading this article you will understand the fundamental mechanics of the injection molding process and how these relate to its key benefits and limitations.

When to use 3D printing vs when to use injection molding

Learn what to consider when making a choice between 3D printing and injection molding, the benefits of each manufacturing method, and more.

How do you design undercuts for injection molding?

Want to learn how to design undercuts that don’t cause damage to your parts? Check out our article, which offers tips and tricks for DFM with undercuts, examples of when you might need them, and more.

Undercuts in injection-molded parts present a host of challenges to designers and manufacturers. In this article, we’ll take a look at the definition of undercuts, their purpose, applications, and tips for designing parts with them.

What is die casting?

Want to learn more about die casting? In this article, we’ll take a look at the process, its history and current uses, advantages, design guidelines, and more.

Why is draft angle design essential for injection molding?

Why is it important to design draft angles for injection molding custom parts? This article covers why draft angles are essential and how to design them better to get the most out of your injection molding designs.

What are injection molding machines and how do they work?

Want to learn more about exactly how an injection molding machine functions, as well as its individual parts? This article puts injection molding machines under the microscope, with detailed descriptions of their components and an in-depth guide to the injection molding process.