Introduction

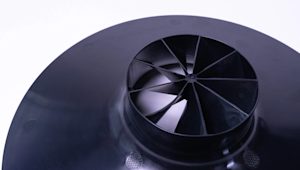

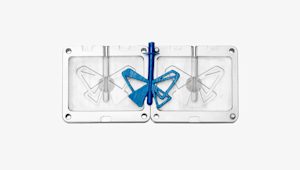

Injection molding is a manufacturing process used to produce parts by injecting molten material – often plastic – into a mold. The material is then cooled and solidified, and the finished part is ejected from the mold.

Injection molding is ideal for producing high-volume, high-precision parts with consistent quality. It is commonly used to create automotive parts, electronic components, medical devices, and consumer goods.

The cost of injection molding depends on factors such as part size and complexity, the type of material used, and the quantity of parts being produced. Typically, the larger and more simple the part, and the higher the quantity, the lower the cost per part.

Types of costs in injection molding

There are different types of costs in injection molding, including equipment costs, mold and tooling costs, material costs, and labor or service costs. As stated above, these costs will vary, depending on complexity, size, quality, materials, and other factors.

Equipment costs of injection molding

These factors influence the cost of injection molding-related equipment.

-

Injection molding machine. This is the primary piece of equipment used for injection molding. The cost of an injection machine will vary depending on its size, complexity, and features, with prices ranging from a few thousand dollars to several hundred thousand dollars.

-

Molds. The cost of molds depends on the size, complexity, and material of the part being produced. A simple mold can cost a few thousand dollars, while a more complex mold can cost tens of thousands of dollars or more.

-

Material handling equipment. This includes equipment such as dryers, hoppers, and conveyors that are used to handle and transport the raw materials used in injection molding.

-

Auxiliary equipment. This includes equipment such as temperature controllers, mold heaters, and cooling equipment that are used to control the temperature of molds and injected material.

-

Tooling and maintenance equipment. This includes equipment such as mold cleaning and maintenance equipment, and tooling and machining equipment used to make and modify molds.

Tooling costs of injection molding

Tooling refers to the design and manufacturing of the mold or tool used to create injection-molded parts. Here are a few cost-related factors for injection molding tooling.

-

Mold design. The cost of mold design depends on the complexity of the part being produced, the number of cavities in the mold, and the level of precision required. This can range from a few thousand dollars to tens of thousands of dollars.

-

Materials. The most common materials used to make molds are steel and aluminum, with steel being more expensive but longer lasting. Overall, the cost of mold materials can range from a few thousand dollars to tens of thousands of dollars.

-

Machining. When machining is needed to create a mold, this can range from a few thousand dollars to tens of thousands of dollars.

-

Tooling maintenance costs. Molds require regular maintenance to ensure they are able to produce high-quality parts. The cost of mold maintenance will depend on the frequency of maintenance and the level of necessary repairs.

Material costs of injection molding

There are a wide range of materials suitable for injection molding, which vary in price.

-

Thermoplastic materials. Thermoplastic materials are the most commonly used materials in injection molding. They include polypropylene, polyethylene, and polystyrene, and typically range from less than a dollar to around $10 per pound.

-

Thermoset materials. Thermoset materials – such as epoxy and phenolic resins – are often used for applications that require parts with temperature or chemical resistance. Because they exhibit specialized properties, the cost of these materials is usually higher than thermoplastic materials.

-

Specialty materials. Glass-filled polymers, elastomers, and foamed materials can be used to achieve specific properties in injection-molded parts. The cost of these materials is generally higher than standard thermoplastic materials.

-

Colorants and additives. Colorants and additives such as UV stabilizers, flame retardants, and impact modifiers can be added to base materials to achieve specific properties or aesthetics. The cost of these additives depends on type and quality.

Labor and service costs of injection molding

The costs of injection molding aren’t solely centered on equipment and materials. Like any business or service, there are many moving parts that require oversight and management. Here are a few of them.

-

Operator labor. Injection molding requires skilled machine operators to operate and maintain injection molding machines. As with any skilled position, exact costs depend on the location and the operator’s experience.

-

Quality control. Quality control is critical to ensure that injection-molded parts meet their required specifications. This may include the cost of manual part inspection, equipment to measure parts, as well as the cost of corrective actions or iterations.

-

Project management. As Protolabs Network manages your injection molding project from beginning to end, this cost includes things like labor, software tools, and associated overhead costs.

-

Shipping and logistics. Shipping and logistics are required to get finished parts to the customer. These costs will depend on the location of the injection molding supplier and the shipping destination.

Reducing the costs of injection molding

You can take several steps to help drive down the costs of injection molding. Here are a few factors to consider.

-

Design optimization. Optimizing a part’s design can help reduce material costs and minimize mold complexity. Simple designs with fewer features can result in lower tooling costs, which can reduce a project’s overall cost. Our automatic DFM analysis identifies potential issues with your design, helping to reduce your costs.

-

Tooling optimization. Optimizing the mold design and manufacturing process can help reduce the tooling cost. Using aluminum rather than steel tooling, for example, can be a cost-effective option for low-volume production runs.

-

Material selection. Less expensive materials can reduce material costs, but it's important to balance cost with part performance – meaning choosing the right material for the job is critical. Protolabs Network is always available to advise on this.

-

Production volume. Higher volume production typically results in lower cost per part due to economies of scale.

-

Automation. Automation can help reduce labor costs and increase production efficiency. Consider incorporating automated or semi-automated systems in the production process to reduce labor costs.

-

Online manufacturing platforms. The right platform can cut costs of injection molding by offering instant quotes, fast turnaround, and help in selecting the right materials for the job, as well as connections to a large network of trusted manufacturers around the world.

To produce a part with injection molding, upload a CAD file to receive a free quote and comprehensive DFM analysis.

You can learn more about the injection molding process including important design considerations, and contact networksales@protolabs.com for personalized advice about your project.

Frequently asked questions

How do you reduce the costs of injection molding?

You can reduce the costs of injection molding by optimizing design and tooling, selecting the right materials, considering production volume, and considering automation for your injection molding process.

What are the advantages of injection molding?

Injection molding offers high production speed, design flexibility, and repeatability with precise tolerances. It is suitable for producing complex parts with consistent quality, and is the most cost-effective option for high-volume production.

What are the disadvantages of injection molding?

Injection molding often comes with high initial tooling costs, limited flexibility for small production runs, and material and part design limitations.

Which industries use injection molding?

Injection molding is widely used in the automotive, consumer goods, medical, and construction sectors due to its ability to produce complex and high-quality parts.

Is injection molding expensive? How do you cut the costs of injection molding?

Injection molding can have high initial costs but is cost-effective for high-volume production. To reduce costs, optimize part design and tooling, select the right materials, and automate your process.

What are the most common applications of injection molding?

Injection molding is commonly used for producing plastic parts such as automotive components, consumer goods, electronics, medical devices, and packaging.