Standard blank sizes for CNC machining (sheets & rods)

Tables of the standard blank sizes (sheets & rods) commonly used in CNC machining.

Introduction

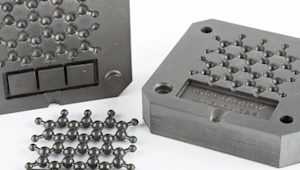

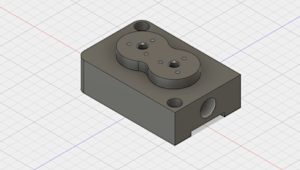

The “blank” in CNC machining is the piece of material (metal or plastic) that is initially loaded to the machine. Stock materials come as plates (for CNC milling) or rods (for CNC turning) in a variety of sizes. In the tables below we summarize the most common blank dimensions found in a typical machine shop.

Note: 0.3 mm to 1.5 mm of material will be removed from each side of the blank during machining (that is up to 3 mm total). This should be taken into account during design as the blank size can significantly increase the material cost for large-scale productions.

Plates

Stock plates come pre-cut to size or as large sheet (typically, 2 m by 1 m - 6 ft. by 3 ft.) that are cut to blanks by the machine shop. So, the limiting dimension for a plate when it comes to design is its thickness.

The table below summarizes the most common aluminum and steel plate thicknesses that can be found in the warehouse of every machine shop. For an extensive, refer to a material supplier catalog.

| Thickness [mm] | Thickness [inches] |

|---|---|

| 3 mm | 3/16'' |

| 4 mm | 1/4'' |

| 5 mm | 5/16'' |

| 6 mm | 3/8'' |

| 8 mm | 7/16'' |

| 10 mm | 1/2'' |

| 12 mm | 5/8'' |

| 15 mm | 3/4'' |

| 20 mm | 1'' |

| 25 mm | 1/2'' increase therafter (up to 5'') |

| 30 mm | |

| 10 mm increase thereafter (up to 100 mm) |

Rods

Rods come as long stock (typically, 1 m - 3 ft. - or longer) that are cut to blanks by the machine shop. The limiting dimension here is the diameter of the rod.

The table below summarizes the most common aluminum and steel plate thicknesses that can be found in the warehouse of every machine shop. For an extensive, refer to a material supplier catalog.

| Diameter [mm] | Diameter [inches] |

|---|---|

| 3 mm | 1/8'' |

| 4 mm | 3/16'' |

| 5 mm | 1/4'' |

| 6 mm | 5/16'' |

| 7 mm | 3/8'' |

| 8 mm | 7/16'' |

| 9 mm | 1/2'' |

| 10 mm | 5/8'' |

| 12 mm | 3/4'' |

| 14 mm | 7/8'' |

| 15 mm | 1'' |

| 16 mm | 1/4'' increase therafter (up to 3'') |

| 20 mm | |

| 25 mm | |

| 30 mm | |

| 40 mm | |

| 10 mm increase therafter (up to 100 mm) |