Black oxide is a conversion coating used on iron, zinc, steel, stainless steel, and copper. It results in a black, smooth surface finish, and improves corrosion resistance and wear resistance. Black oxide is commonly used as a surface finish in a variety of industrial and commercial applications, including automotive and aerospace components, machinery and tools.

A brief history of black oxide

The exact origin or inventor of black oxide coating is not well documented, but the process of blackening iron and steel has been used for centuries by blacksmiths and metalworkers. It was – and is – seen as a full or partial solution to several challenges.

What were the early uses of black oxide coating?

-

Preventing corrosion. Black oxide coating helps improve metal components’ resistance to corrosion and rust, extending their lifespans and reducing the need for expensive or time-consuming repairs or replacements.

-

Reduced wear. Black oxide enhances the hardness and durability of metal surfaces, reducing wear and tear and improving the performance of metal components in hard-working or industrial environments.

-

Aesthetics. With a smooth, matte finish, black oxide improves the appearance of metal components, making them easier to incorporate into a variety of applications, as their visibility is not an issue.

-

Reduced light reflection. For a variety of functional and cosmetic applications, a black oxide coating makes surfaces less reflective.

What is black oxide predominantly used for now?

Black oxide is still used to achieve the above results, and is well-suited for applications that require a durable, low-maintenance, and corrosion-resistant surface finish, such as:

-

Fasteners, hardware, and tools. Black oxide is a popular finish for fasteners such as screws, nuts, bolts, as well as hand tools and other hardware, as it provides a matte, aesthetically pleasing finish that is corrosion-resistant, durable, and easy to grip.

-

Automotive and aerospace components. In the automotive and aerospace industries, black oxide is used as a surface finish for a variety of parts, including engine components, suspension systems, and landing gear.

-

Industrial equipment. Black oxide is used to finish a wide range of industrial equipment, such as pumps, valves, and machinery, to provide corrosion- and wear-resistant surfaces.

How does black oxide work?

Black oxide is a finishing process that involves immersing a part in a solution including sodium hydroxide and potassium nitrate. At Protolabs Network, applying black oxide is a six-step process, in which a part is:

-

Run through machining and deburring

-

Cleaned using alkaline solutions

-

Rinsed in water

-

Black-oxidized via immersion in a hot (135-145ºC) alkaline bath for a period of five to 40 minutes, depending on the size of the part

-

Rinsed in water once again

-

Given an after-finish treatment with oil, lacquer, or wax to seal the oxide surface

What’s the difference between black oxide and other surface finishes?

Black oxide differs from other popular surface finishes in several ways.

-

Aesthetics. While other metal finishes, such as anodizing, electroplating, and powder coating, offer a variety of color options, black oxide provides a unique, matte black finish.

-

Durability. Black oxide provides a durable, corrosion-resistant surface that is often more wear-resistant than other finishes.

-

Process. Creating a black oxide finish is relatively simple and cost-effective compared to other finishes, such as electroplating or anodizing.

Design considerations for black oxide parts

Consider these important factors when using black oxide coating.

-

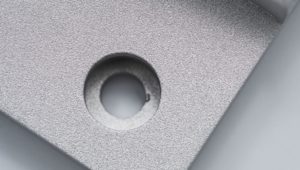

Coat thickness. The thickness of black oxide coating depends on several factors, including the type of metal being coated, the method used to produce the black oxide coating, and the desired level of protection, with thicker coatings providing increased protection. Typically, however, black oxide coatings are between 0.0002 to 0.0006 inches thick.

-

Use on stainless steel. It is possible to use black oxide coating on stainless steel. While stainless steel is naturally rust and corrosion resistant, a black oxide coating can provide additional protection as well as enhance its aesthetic qualities.

Best practices for black oxide coating

Follow these tips and note some design limitations for black oxide coatings.

-

Complex geometries. Parts with complex geometries and tight corners may not be suitable for black oxide coating, as it can be difficult to achieve a uniform coating on these surfaces.

-

Surface finish. Black oxide coating works best on surfaces with a smooth, uniform finish, as rougher surfaces can result in a less uniform coating.

-

Material compatibility. Not all metals are compatible with black oxide coating. Some metals, such as aluminum, do not react well with the black oxide process, which can result in a poor-quality finish.

-

Corrosion resistance. While black oxide provides some protection against corrosion, it is not as effective as other finishes such as anodizing or electroplating.

-

Masking. Black oxide does not have a significant dimensional impact, therefore masking parts is not necessary.

To produce a part with a black oxide coating, upload a CAD file for an instant quote and automatic DFM analysis. You can also read more about our black oxide service, as well as other optional surface finishes for your parts.

For further information or recommendations on finishes or materials with the right properties for your project, contact networksales@protolabs.com.

Frequently asked questions

What are the advantages of black oxide coating surface finishing?

Black oxide provides parts with improved corrosion resistance, wear resistance, durability, and aesthetics.

What are the disadvantages of black oxide coating surface as a surface finish?

Black oxide is not as corrosion-resistant as other surface finishes, and can be difficult to repair if damaged.

Which industries use black oxide coating?

Black oxide is used in the automotive, aerospace, and manufacturing industries for a wide variety of commercial and industrial applications.

Why should you choose black oxide-coated products?

Black oxide improves the corrosion and wear resistance of metal parts, as well as their aesthetic qualities.

Is black oxide coating expensive? How do you cut costs on black oxide coating?

Applying black oxide is a relatively simple process, meaning it is often more affordable than other surface finishes. To cut costs further, consider batch production or thinner overall coatings.

What are the most common applications of black oxide coating?

Black oxide coating is commonly used on automotive and aerospace parts, tools, fasteners, industrial equipment, and firearm components.