What is passivation?

Passivation involves treating a metal surface with an acid solution to remove free iron and other contaminants to restore the thin, protective oxide layer. This oxide layer acts as a shield, preventing the metal from reacting with its environment and reducing the risk of corrosion. Passivation is commonly used on stainless steel and other metals to improve their resistance to rust, staining, and other forms of deterioration.

Stainless steels are the most common materials that require passivation, which is typically achieved with nitric or citric acid. Anodizing is also a common method of passivation, which is commonly used on aluminum, as well as magnesium and titanium. The protective oxide layer this treatment provides also allows for the metal to be dyed. Read more about how anodizing works. passivated with nitric or citric acid. Additionally, electropolishing can be used to achieve passivation.

How does passivation work?

The passivation process involves several steps. First, the metal surface is thoroughly cleaned to remove any contaminants. Then, the cleaned metal is immersed in an acid solution – usually a mixture of nitric acid and water – which removes or eliminates free iron and other impurities from the surface.

As the acid reacts with the metal, it triggers the formation of a very thin oxide layer composed of metal oxides – like chromium oxide, in the case of stainless steel. Although this layer is incredibly thin and invisible, it plays a vital role as a protective barrier. By acting as a shield between the metal and the environment, the oxide layer prevents oxygen and moisture causing corrosion or rust.

What materials are used in passivation?

Passivation is commonly used on stainless steel, but it can also be applied to metals like titanium, aluminum, and magnesium in the form of anodizing. The primary focus is on metals that naturally form a protective oxide layer, which contributes to their corrosion resistance. The passivation process is particularly important for stainless steel, where it helps maintain the integrity of the oxide layer on the surface, ensuring continued corrosion resistance.

What are the advantages of passivation?

There are several key reasons for applying passivation to parts as a post process. Here are its benefits.

-

Corrosion resistance. Passivation creates a protective oxide layer on the metal's surface, significantly improving its resistance to corrosion and rust in various environments.

-

Durability. Treated metals have a longer lifespan due to reduced susceptibility to degradation caused by exposure to corrosive agents, moisture, and other environmental factors.

-

Maintained properties. Passivation preserves the inherent properties of metals, such as their mechanical strength and electrical conductivity, while making them more resistant to corrosion-related degradation.

-

Long-term cost savings. By preventing corrosion and the need for frequent replacements, passivation can lead to substantial cost savings over the long term, especially in industries where equipment durability is critical.

What are the disadvantages of passivation?

While passivation offers numerous benefits, there are also some potential disadvantages to consider. Here are a few of the most common.

-

Complexity. Passivation involves precise control of chemicals, concentrations, and process parameters, which can make it more complex and time-consuming than other surface treatment methods. Additionally, treating large or intricate metal components can be challenging, as ensuring uniform coverage across all surfaces may be difficult.

-

Limited effect on existing damage. Passivation is best suited for preventing corrosion on clean surfaces. It may have limited effectiveness in restoring severely corroded or damaged metal surfaces.

-

Material limitations. Passivation is most effective for metals that naturally form a protective oxide layer. It may not be as suitable for materials that don't readily develop this layer.

Best practices for designing parts for passivation

By incorporating these best practices, you can increase the likelihood of achieving consistent and effective passivation results for your parts while minimizing potential challenges.

-

Material selection. Choose materials that naturally form a protective oxide layer, such as stainless steel. Avoid materials that might not benefit from passivation or could be adversely affected by the process.

-

Avoid complex shapes. Design parts with simple, accessible geometries. Complex shapes with crevices, corners, and hard-to-reach areas can trap chemicals and hinder proper rinsing during the passivation process.

-

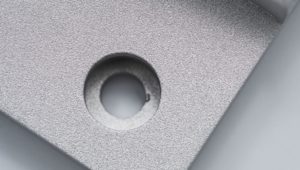

Smooth surfaces. Opt for smooth surface finishes with minimal surface defects. Smooth surfaces are easier to clean and passivate effectively.

-

Eliminate sharp corners. Sharp corners and edges can be difficult to passivate uniformly. Rounded edges are more amenable to passivation and rinsing.

-

Minimize welds. If possible, minimize the number of welds on a part or consider designing them in a way that avoids tight crevices where chemicals might accumulate.

-

Proper drainage. Ensure proper drainage by designing parts to allow liquids to flow freely and not get trapped in recesses. This prevents the accumulation of passivation chemicals.

-

Clearances and gaps. Provide adequate clearances and gaps between components to allow proper chemical circulation and rinsing during the passivation process.

-

Deburring. Remove burrs and sharp edges, as they can harbor contaminants and complicate the passivation process.

Which industries use passivation?

Passivation is widely used in industries such as aerospace, pharmaceuticals, food processing, and electronics to ensure the longevity and reliability of metal components in various applications. Let’s take a look at these industries, and the applications used within them.

-

Aerospace. Aerospace applications involve passivation to protect critical components like aircraft turbine blades and structural elements from corrosion in demanding and varied environments.

-

Pharmaceuticals. Passivation is crucial for pharmaceutical manufacturing equipment, ensuring that stainless steel vessels and piping maintain sanitary conditions and resist corrosion during drug production.

-

Food processing. Passivation is employed in food processing equipment, safeguarding stainless steel tanks and machinery from corrosion, and ensuring compliance with sanitation standards.

-

Electronics. In electronics manufacturing, passivation protects sensitive components and connectors on circuit boards from environmental factors, enhancing their reliability and longevity.

-

Medical devices. In the medical industry, passivation increases the biocompatibility and corrosion resistance of surgical implants such as orthopedic implants and cardiovascular stents.

-

Automotive. Passivation finds use in automotive parts such as engine components and exhaust systems, enhancing corrosion resistance and durability, especially in regions with harsh weather conditions.

Order parts with passivation

To get an instant quote for a custom part with anodizing as a post-process, upload a CAD file for instant pricing and lead times. Passivation for steel and other metals is available as a custom request. Contact support@hubs.com to discuss your requirements.

You can also read more about post-processing and surface finishes, and how to choose the right process for CNC machined parts.

Frequently asked questions

Why is passivation needed?

It prevents corrosion, extends lifespan, and maintains metal properties.

What metals can be passivated?

Stainless steel, titanium, aluminum, and other corrosion-resistant metals are all good candidates for passivation.

Is passivation permanent?

While passivation offers long-term protection, it can degrade over time in aggressive environments.

Can passivated parts rust?

Passivation reduces rust but doesn't eliminate it entirely, meaning upkeep is essential.

Can existing rust be passivated?

Passivation works best on clean surfaces; it's less effective on heavily rusted areas.

Is passivation safe?

When properly managed, yes. However, the passivation process involves handling chemicals and adhering to safety protocols.