CNC-Frässervice

Beziehen Sie kundenspezifische Teile aus unserem Netzwerk aus spezialisierten Fertigungspartnern für das CNC-Fräsen. Sie können kundenspezifische Frästeile aus über 50 verschiedenen Metallen und Kunststoffen fertigen lassen und es sind über 15 Oberflächenveredelungen sowie Toleranzen bis zu 0,020 mm möglich.

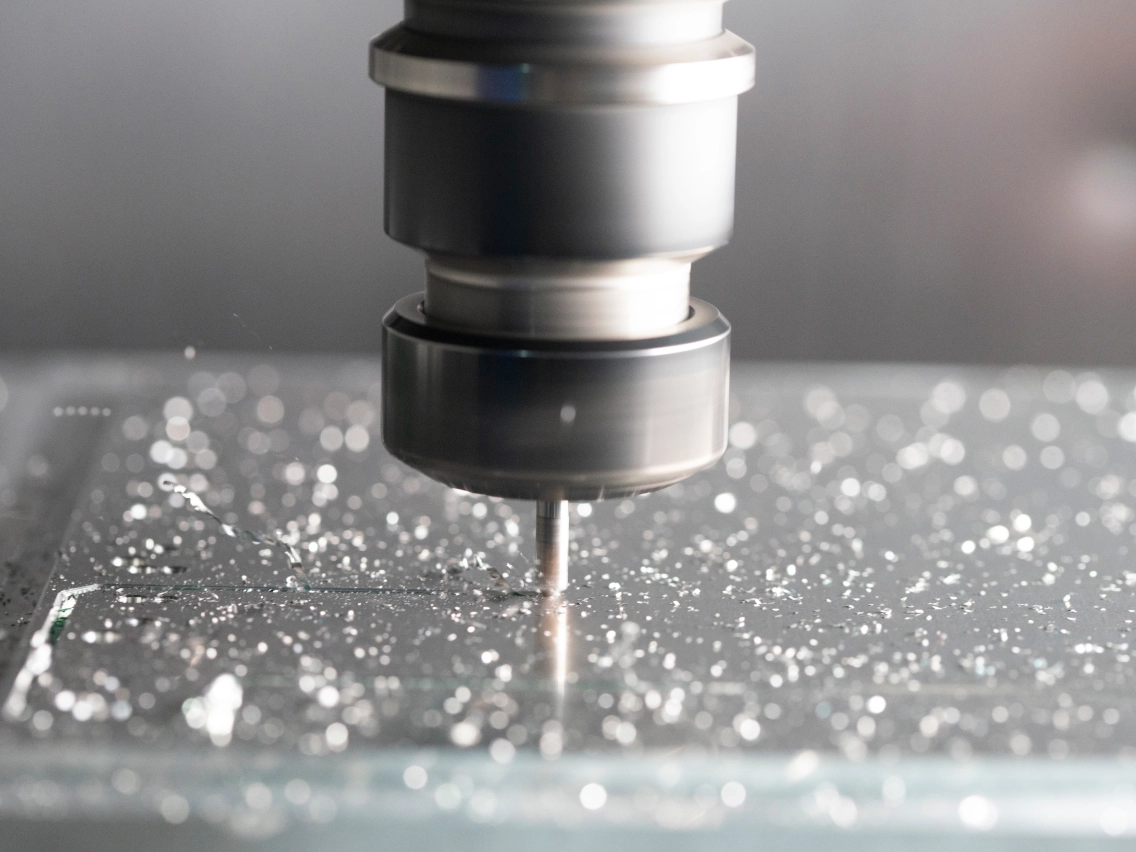

Was ist CNC-Fräsen?

Beim CNC-Fräsen kommen drehende Schneidwerkzeuge zur Anwendung, die Material von einem Werkstück entfernen, um Endteile und -produkte herzustellen. Dieses Fertigungsverfahren eignet sich großartig für viele Materialien, einschließlich Metalle, Polymere, Holz und Glas. CNC-Frässysteme verfügen im Allgemeinen über 3 lineare Bewegungsachsen: die X-, Y- und Z-Achse. Damit ist höchste Präzision und Detailgenauigkeit möglich. Darüber hinaus bietet Protolabs Network höher entwickelte 5-Achs-Systeme an, bei denen der Werkzeugkopf und das Maschinenbett (A- und B-Achse) auch drehbar sind. Mit 5-Achs-CNC-Maschinen können Teile mit hoher geometrischer Komplexität ohne mehrere Maschineneinstellungen hergestellt werden.

Weitere Informationen zum CNC-Fräsen und -Drehen

Maximale Teilegröße für das 3- und 3+2-Achs-CNC-Fräsen

Es sind mehrere Arten von CNC-Fräsmaschinen verfügbar, die alle für eine unterschiedliche maximale Teilegröße ausgelegt sind. Bei 3-Achs- und 3+2-Achs-Maschinen sind die Start-up-Kosten am niedrigsten und die Maschinen können Teile mit relativ einfachen Geometrien herstellen.

3-Achs-Fräsen

| Größe | Metrische Einheiten | Einheiten, britisches System |

|---|---|---|

| Maximale Teilegröße für Weichmetalle [1] und Kunststoffe | 2000 x 1500 x 200 mm 1500 x 800 x 500 mm | 78.7 x 59.0 x 7.8 in 59.0 x 31.4 x 27.5 Zoll |

| Maximale Teilegröße für Hartmetalle [2] | 1200 x 800 x 500 mm | 47.2 x 31.4 x 19.6 Zoll |

| Mindest-Merkmalsgröße | Ø 0.50 mm | Ø 0.019 Zoll |

| [1]: Aluminium, Kupfer und Messing [2]: Edelstahl, Werkzeugstahl, legierter Stahl und Baustahl |

3+2-Achs-Fräsen

| Größe | Metrische Einheiten | Einheiten, britisches System |

|---|---|---|

| Maximale Teilegröße für Weichmetalle [1] und Kunststoffe | 2000 x 1500 x 200 mm | 78.7 x 59.0 x 7.8 Zoll |

| Maximale Teilegröße für Hartmetalle [2] | 1200 x 800 x 500 mm | 47.2 x 31.4 x 19.6 Zoll |

| Mindest-Merkmalsgröße | Ø 0.50 mm | Ø 0.019 Zoll |

| [1] Aluminium, Kupfer und Messing [2] Edelstahl, Werkzeugstahl, legierter Stahl und Baustahl |

Maximale Teilegröße für das 5-Achs-CNC-Fräsen

Beim 5-Achs-Fräszentrum handelt es sich um eine fortschrittlichere Maschine unter den Fräsmaschinen. Damit können komplexere Geometrien gefertigt werden. Diese Maschinen erfordern weniger Maschineneinstellungen und sind daher produktiver.

| Größe | Metrische Einheiten | Einheiten, britisches System |

|---|---|---|

| Maximale Teilegröße für alle Materialien | 2000 x 1500 x 200 mm | 78,7 x 59,0 x 7,8 Zoll |

| Mindest-Merkmalsgröße | Ø 0,50 mm | Ø 0,019 Zoll |

Verfügbare Materialien für das CNC-Fräsen

Ein breites Spektrum an Metallen für die CNC-Bearbeitung mit Anwendungen in mehreren Branchen. Ideal sowohl für einzelne Prototypen als auch für kundenspezifische Endverbrauchsteile.

Ein breites Spektrum an Kunststoffen für die CNC-Bearbeitung mit Anwendungen in mehreren Branchen. Ideal sowohl für einzelne Prototypen als auch für kundenspezifische Endverbrauchsteile.

Oberflächenveredelungen für das CNC-Fräsen

Steigern Sie die Leistung Ihres Teils, indem Sie eine qualitativ hochwertige Oberflächenveredelung auswählen, die die Rauheit, Härte, chemische Widerstandsfähigkeit und kosmetischen Merkmale des fertigen Bauteils verbessern.

Oberflächenveredelungen für das CNC-Fräsen durchstöbern

CNC-Frästoleranzen

Wir folgen den ISO 2768-Standards für die CNC-Bearbeitung.

| Grenzwerte für Nenngröße | Kunststoffe (ISO 2768- m) | Metalle (ISO 2768- f) |

|---|---|---|

| 0,5 mm* bis 3 mm | ±0,1 mm | ±0,05 mm |

| Über 3 mm bis 6 mm | ±0,1 mm | ±0,05 mm |

| Über 6 mm bis 30 mm | ±0,2 mm | ±0,1 mm |

| Über 30 mm bis 120 mm | ±0,3 mm | ±0,15 mm |

| Über 120 mm bis 400 mm | ±0,5 mm | ±0,2 mm |

| Über 400 mm bis 1000 mm | ±0,8 mm | ±0,3 mm |

| Über 1000 mm bis 2000 mm | ±1,2 mm | ±0,5 mm |

| Über 2000 mm bis 4000 mm | ±2 mm | |

| *Bitte weisen Sie in auf Toleranzen für Nenngrößen unter 0,5 mm deutlich in Ihrer technischen Zeichnung hin. |

Designrichtlinien für das CNC-Fräsen

Sehen Sie sich die empfohlenen und technisch machbaren Werte für die am häufigsten auftretenden Merkmale bei CNC-bearbeiteten Teilen an.

Weitere Informationen in unserem Ingenieurleitfaden für die CNC-Bearbeitung

| Merkmal | Empfohlene Größe | Machbare Größe |

|---|---|---|

| Mindest-Merkmalsgröße | Ø 2,5 mm | Ø 0,50 mm |

| Innenkanten | R 8 mm | R 0,25 mm |

| Mindest-Wandstärke | 0,8 mm (für Metalle) 1,5 mm (für Kunststoffe) | 0,5 mm (für Metalle) 1,0 mm (für Kunststoffe) |

| Löcher | Durchmesser: Standard-Bohrergrößen Tiefe: 4 x Durchmesser |

Durchmesser: Ø 0,5 Tiefe: 10 x Durchmesser |

| Gewinde | Größe: M6 oder größer Länge: 3 x Durchmesser | Größe: M2 |

Warum Sie sich für das CNC-Fräsen entscheiden sollten

Wir haben hohe Standards in Bezug auf das CNC-Fräsen

Wir stellen Ihre spezifischen Teile nach strikten Fertigungsstandards her und gewährleisten, dass alle Teile und Verfahren den Protolabs-Network-Standard einhalten.

-

Es sind mehrere Oberflächenveredelungen verfügbar, um die kosmetische Qualität Ihrer Teile nach der Bearbeitung zu verbessern.

-

Jedes spezifische Teil wird von unseren Fertigungspartnern gemäß unseren Richtlinien vor Ort geprüft.

-

Auf Anfrage sind Prüfberichte und andere Arten von Qualitätsdokumentation erhältlich, um höchste Qualität und Compliance sicherzustellen.

Weitere Ressourcen zum CNC-Fräsen

Erfahren Sie mehr darüber, wie das CNC-Fräsen funktioniert und wie Sie Teile designen können, um das meiste aus diesem Bearbeitungsverfahren herauszuholen.