Surface finishes

Aluminiumeloxierdienste

Wir bieten Eloxieren Typ II und III an. Hierbei handelt es sich um ideale Oberflächenveredelungen für Aluminiumteile. Durch das Eloxieren werden Aluminiumteile verstärkt und es sind je nach Typ verschiedene Farben verfügbar. Alle Eloxaltypen führen zu erhöhten Vorlaufzeiten und Kosten pro Teil.

Eloxieren, Typ II

| Oberflächenvorbereitung | Farben | Glanz | Kosmetische Verfügbarkeit | Stärke** | Optisches Erscheinungsbild |

|---|---|---|---|---|---|

| Geschlichtet (Ra 3,2 μm/Ra 126 μin) | Klar, Schwarz, Rot, Blau, Orange, Gold | Glänzend (über 20 GU) | Nein | Für Klar: 8 bis 12 μm (0,008 mm bis 0,012 mm); Schwarz und Farbe: 12 bis 16 μm (0,012 mm bis 0,016 mm) | Teile werden direkt nach der Fertigung eloxiert. Bearbeitungsspuren sind sichtbar. |

| Perlengestrahlt | Klar, Schwarz, Rot, Blau, Orange, Gold | Matt (unter 10 GU) | Kosmetisch auf Anfrage | Für Klar: 8 bis 12 μm (0,008 mm bis 0,012 mm); Schwarz und Farbe: 12 bis 16 μm (0,012 mm bis 0,016 mm) | Körnige Oberflächenstruktur, mattes Finish |

| Perlengestrahlt | Klar, Schwarz, Rot, Blau, Orange, Gold | Glänzend (über 20 GU) | Kosmetisch auf Anfrage | Für Klar: 8 bis 12 μm (0,008 mm bis 0,012 mm); Schwarz und Farbe: 12 bis 16 μm (0,012 mm bis 0,016 mm) | Körnige Oberflächenstruktur, glänzendes Finish |

| Schleifen (Ra 1,2 μm/Ra 47 μin) | Klar, Schwarz, Rot, Blau, Orange, Gold | Glänzend (über 20 GU) | Kosmetisch auf Anfrage | Für Klar: 8 bis 12 μm (0,008 mm bis 0,012 mm); Schwarz und Farbe: 12 bis 16 μm (0,012 mm bis 0,016 mm) | Teile werden manuell geschliffen, um Bearbeitungsspuren zu verringern, und anschließend eloxiert. Schleiflinien sind sichtbar. |

Eloxieren, Typ III

| Oberflächenvorbereitung | Farben | Kosmetische Verfügbarkeit | Stärke | Optisches Erscheinungsbild |

|---|---|---|---|---|

| Geschlichtet (Ra 3,2 μm/Ra 126 μin) | Schwarz, Natur (stärkere Schichten wirken dunkler) | Nein | 35 bis 50 μm (0,033 mm bis 0,050 mm) | Teile werden direkt nach der Bearbeitung eloxiert. Bearbeitungsspuren sind sichtbar. |

| Perlengestrahlt (Glasperlen #120) | Schwarz, Natur (stärkere Schichten wirken dunkler) | Kosmetisch auf Anfrage | 35 bis 50 μm (0,033 mm bis 0,050 mm) | Können bei nicht-kosmetischen Teilen leicht sichtbar sein; bei kosmetischen Teilen vollständig entfernt |

* Wir stellen eine Vielzahl von Standardfarben bereit (siehe Farboptionen). Falls Sie einen bestimmten RAL- oder Pantone-Farbcode benötigen, wenden Sie sich bitte an networksales@protolabs.com.

**Unsere Eloxalstärke entspricht standardmäßig ISO 7599: ISO-Norm AA10 (für transparent) und ISO-Norm AA15. Falls für Ihre Teile andere Standards angewendet werden sollen, wenden Sie sich bitte an networksales@protolabs.com.

Farboptionen für das Eloxieren

Beim farbigen Eloxieren kann es aufgrund von Unterschieden bei den standardmäßigen Legierungstoleranzen zu unterschiedlichen Farben kommen. Das Farbschema unten zeigt die Farbskala.

Farboptionen für das Eloxieren von Aluminium, Typ III

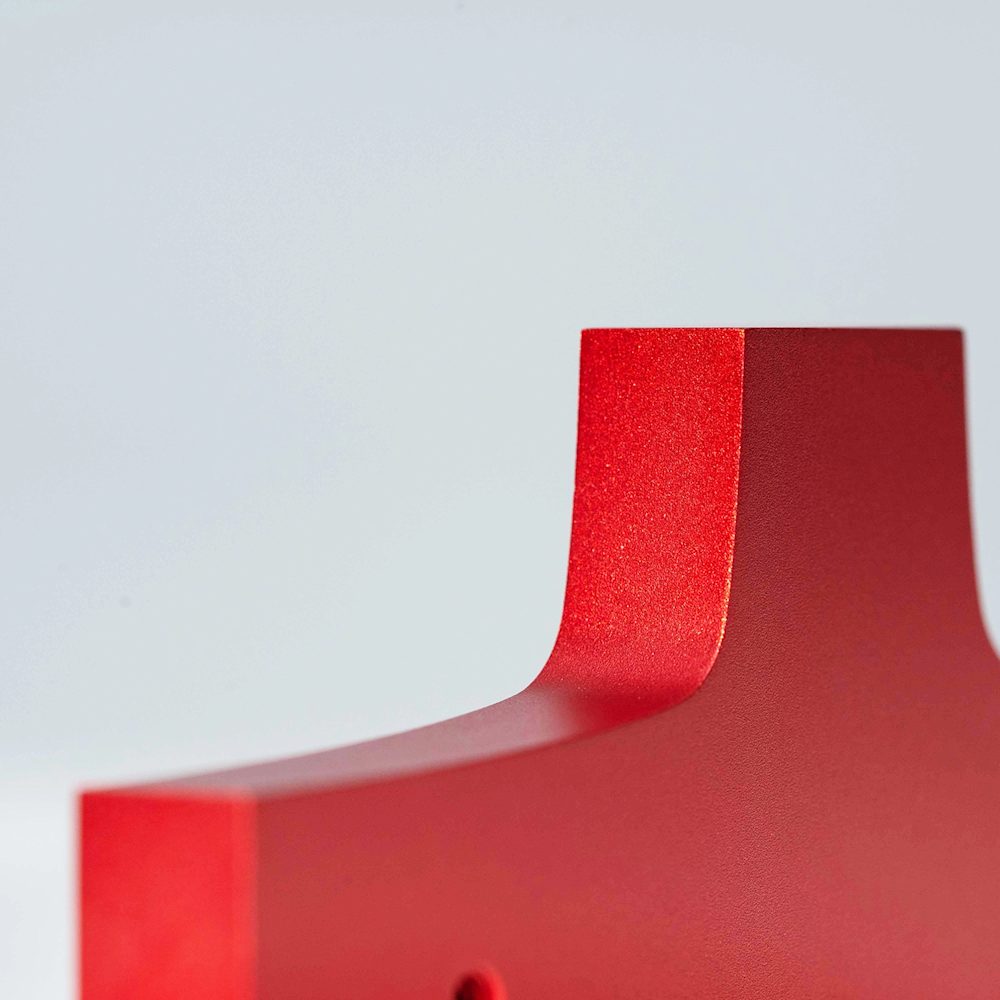

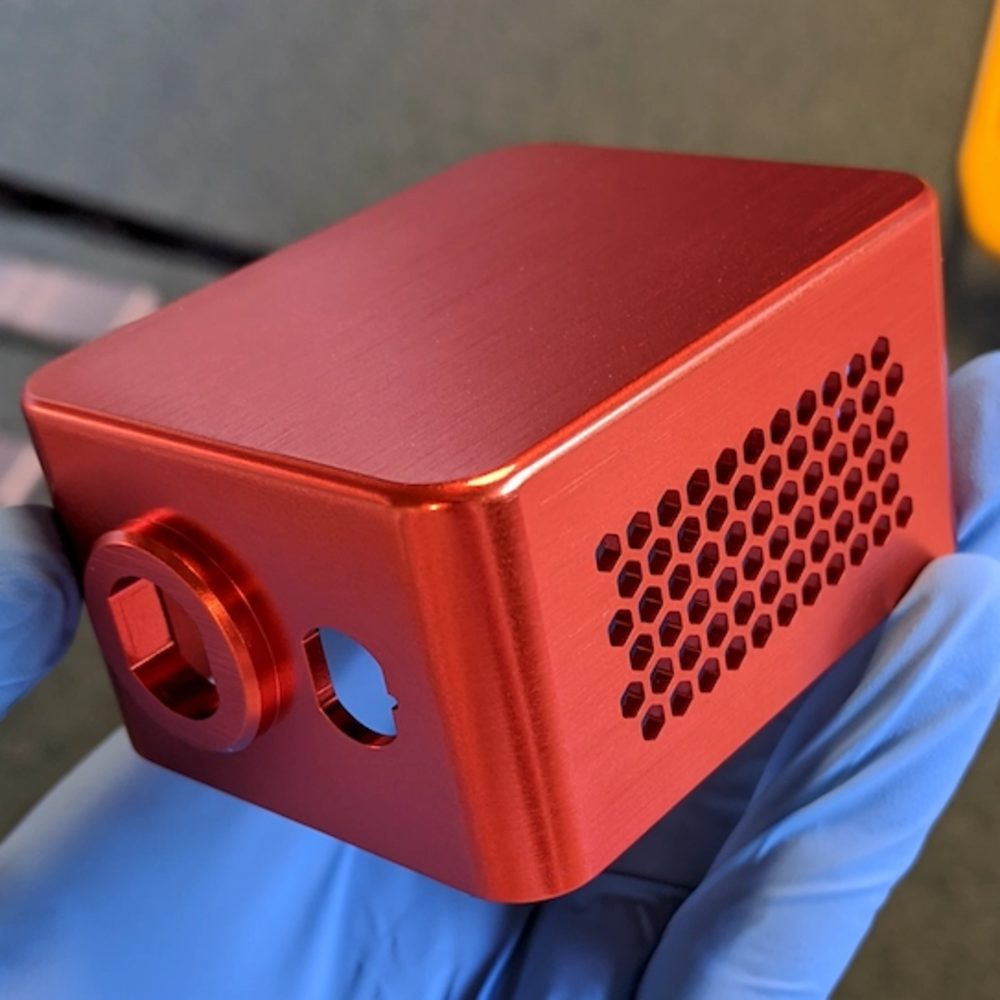

Beispiel eines eloxierten Teils

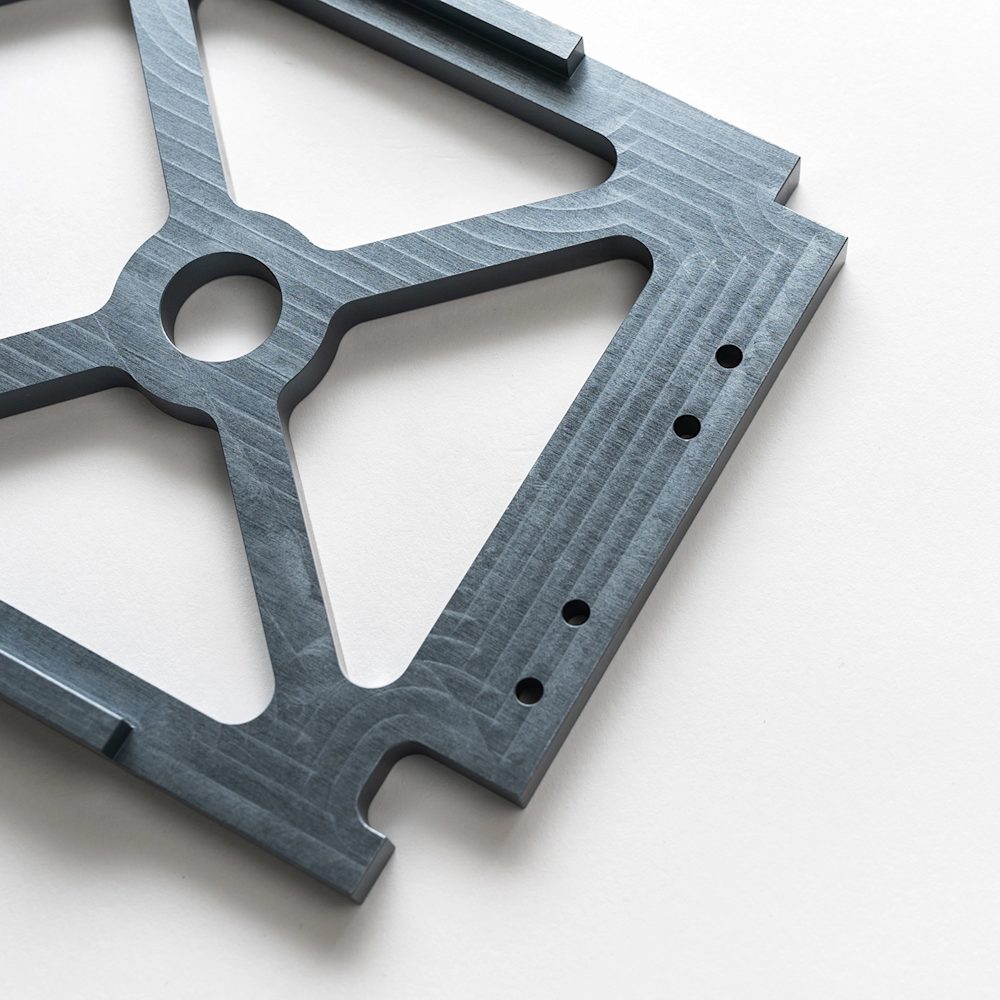

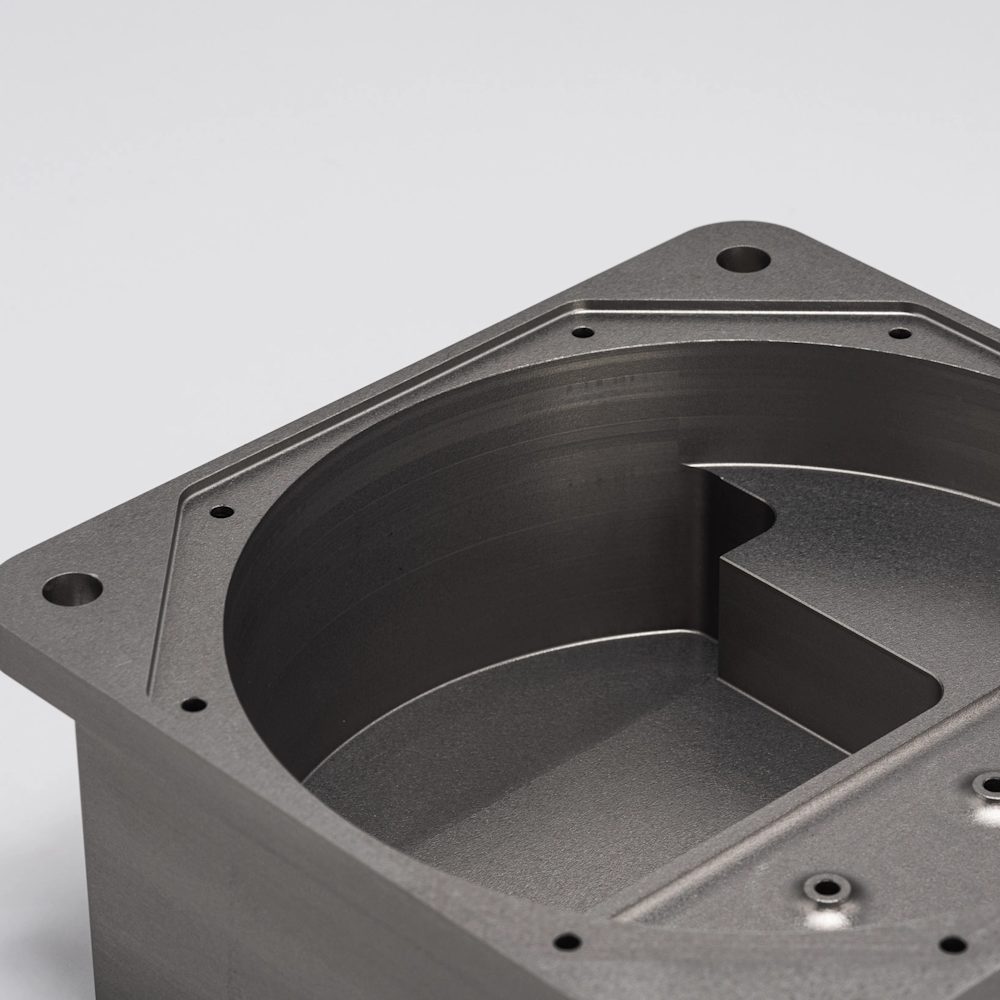

Galerie von eloxierten Teilen

Designüberlegungn für das Eloxieren

- Beim Eloxieren werden Teile in einer Einspannvorrichtung oder in einem Gestell befestigt. Dies führt an den Stellen, an denen kein Eloxieren möglich war, zu Markierungen. Weitere Informationen hierzu finden Sie auf unserer Oberflächenveredelungsseite.

- Durch das Eloxieren werden Ihre Teile isoliert, was zu einer Verringerung der Leitfähigkeit führt.

- Es ist typischerweise nicht erforderlich, Teile abzukleben, da das Eloxieren nicht zu einer erheblichen Erhöhung der Stärke Ihres Teils führt. Bitte denken Sie daran, in Ihrer CAD-Datei anzugeben, falls bestimmte Bereiche Ihres Teils abgeklebt oder verschlossen werden sollen.

- Beim Eloxieren, Typ III kommt es dagegen zu einer beträchtlichen Schicht auf der Oberfläche Ihres Teils. Daher empfehlen wir in solchen Fällen, Gewindebohrungen/Passlöcher oder andere für die Funktion kritische Oberflächen abzukleben bzw. entsprechend zu verschließen.

Unser Eloxalverfahren

Beim Eloxieren handelt es sich um ein elektrolytisches Verfahren, das sowohl zum Schutz von Aluminiumteilen vor Verschleiß und Korrosion als auch zur Verbesserung des kosmetischen Aussehens dient. Das Eloxalverfahren eines Teils besteht aus folgenden Schritten:

-

Teil an eine Anode anschließen.

-

Teil in eine säurehaltige Elektrolytlösung eintauchen.

-

Kathode an einer Metallelektrode in der Lösung befestigen.

-

Positive Ionen reagieren mit negativen O2-Ionen und die Oberfläche wird porös.

-

Dadurch entsteht eine Aluminiumoxidschicht auf dem Teil.

-

Korrosionsschutzmittel oder Färbungsmittel für kosmetische Zwecke verwenden.

-

Nanoporen versiegeln.

Videoressourcen für das Eloxal-Verfahren

Beginnen Sie noch heute mit der Produktion Ihrer eloxierten Teile.

Sofortangebot anfordern