Online CNC machining service

On-demand CNC machining service for rapid prototyping and production parts, through a network of specialized, experienced and thoroughly vetted local and global CNC machine shops.

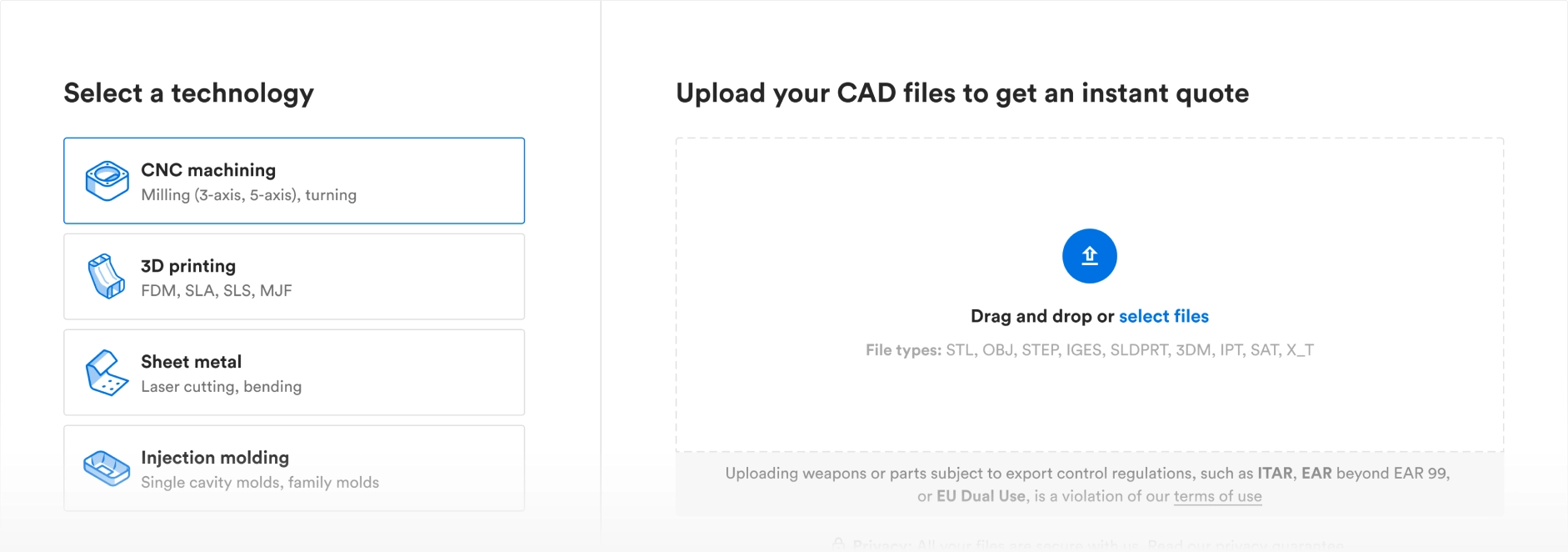

Get instant CNC machining quote All uploads are secure and confidentialThe easiest way to machine parts

From prototype to production volumes using one unified platform.

Instant pricing

Get instant prices and lead times for more than 100 combinations of materials and finishes.

Quality & compliance

Quality documentation including COC, REACH, RoHS and material certificates. ISO 9001, AS9100, ISO 13485, ISO 14001 and ISO TS16949.

Specialized network

Access machine shops throughout our network of more than 250 vetted manufacturing partners.

Production volumes

Volume pricing for production quantities. Expertise in high-mix configurations requiring extensive customization.

CNC processes

- Tolerances down to ±.020 mm (±.001 in)

- Quality control and documentation

- Broad range of surface finishes

- Lead times from 5 business days

-

CNC turning

Produces parts by mounting a blank on a rotating chuck and removing material.

-

3 & 5 axis CNC milling

Creates complex geometries using 3 linear degrees of freedom: the X, Y, and Z axis.

Order specifications

We can generate instant machining quotes for 50+ metals and plastics.

Aluminum 7075-T7351 | 3.4365 | 76528 | AlZn5.5MgCu Aluminum 7075-T7351 | 3.4365 | 76528 | AlZn5.5MgCu Aluminum 6061-T651 | 3.3211 | 65028 | AlMg1SiCu Aluminum 7075-T651 | 3.4365 | 76528 | AlZn5.5MgCu Aluminum 6082-T651 | 3.2315 | 64430 | AlSi1MgMn Aluminum 6060 | 3.3206 | AlMgSi Aluminum 5052 | EN AW-5052 | 3.3523 | AlMg2,5 Aluminum 2017A | 3.1325 | 24530 | AlCu4MgSi Aluminum 2014 | 3.1255 | 24345 | AlCu4SiMg Aluminum 6063 | EN AW-6063 | 62400| AlMg0,7Si Aluminum 7050 | EN AW-7050 | 3.4144| AlZn6CuMgZr Aluminum 2024-T351 | 3.1355 | 24530 | AlCu4Mg1 Aluminum MIC6 Aluminum 7075-T6 | 3.4365 | 76528 | AlZn5,5MgCu Aluminum 5083-H111 | 3.3547 | 54300| AlMg4.5Mn0.7 Aluminum 6082 | 3.2315 | 64430| AlSi1MgMn Aluminum 6061-T6 | 3.3211| 65028| AlMg1SiCu

Stainless steel 416 | 1.4005 | X12CrS13 Stainless steel 15-5 | 1.4545 | X5CrNiCu15-5 Stainless steel 301 | 1.4310 | X10CrNi18-8 Stainless steel 430 | 1.4016 | X6Cr17 Stainless steel 440C | 1.4125 | X105CrMo17 Stainless steel 420 | 1.4028 | X30Cr13 Stainless steel 304/304L | 1.4301/1.4307 | X5CrNi18-10/X2CrNi18-9 Stainless steel 2205 Duplex | 1.4462 | 2205 | X2CrNiMoN 22-5-3 Stainless Steel 17-4 PH | 1.4542 | X5CrNiCuNb16-4 - Annealed state Stainless steel 303 | 1.4305 | X8CrNiS18-9 Stainless steel 316/316L | 1.4401/1.4404 | X5CrNiMo17-12-2/X2CrNiMo17-12-2

Mild steel S275JR | 1.0044 | Fe430B | IS2062 Mild Steel S235JR | 1.0038 | Fe 360 B Carbon steel C45 | 1.0503 | 1045 | EN8 Mild steel S355J2 | 1.0577 | 1522H | Fe 510 D Mild steel 1045 | 1.0503 | C45 | EN8 Mild steel A36 | 1.025 | Fe 410 Mild steel 1018 | 1.1147 | C18 |16Mn

Brass Cz121 | C38500 | 2.0401 | CuZn39Pb3 Brass C360 | 2.0375 | CuZn36Pb3 | 319 grade 2

Copper C101 | CU OFE Copper C110 | CU ETP

Alloy steel 1.7131 | 16MnCr5 Alloy steel 1215 | EN1A | 1.0715 Alloy steel 4340 | 1.6511 | 36CrNiMo4 | EN24 Alloy steel 4140 | 1.7225 | EN19 | 42CrMo4

Tool steel A3 - Annealed state Tool steel H13 | 1.2344 | X40CrMoV5-1 - Annealed state Tool steel S7 | 1.2355 | 50CrMoV13-15 - Annealed state Tool steel O1 | 1.2510 | 100MnCrW4 - Annealed state Tool steel A2 | 1.2363 | X100CrMoV5-1- Annealed state Tool steel D2 | 1.2379 | X153CrMoV12-1 - Annealed state

Titanium Grade 5 | 3.7164 | Ti6Al4V Titanium Grade 2 | 3.7035 Titanium Grade 1 | 3.7025

Inconel 718

Invar 36

Acetal Copolymer (POM-C) FDA Acetal Copolymer (POM-C) ESD Acetal Copolymer (POM-C) Acetal Homopolymer (POM-H)

Nylon 6 Flame Retardant Nylon 6/6 30% Glass Filled Nylon 6 30% Glass Filled Nylon 6

PPSU | UL94 V-0

ABS

PEEK

PTFE

PC

UHMW-PE HDPE

PMMA (Acrylic)

PET

PP Homopolymer PP+GF(30%) PP

Garolite G-10

FR4

PEI Ultem 1000 PEI Ultem 2300 30% Glass Filled

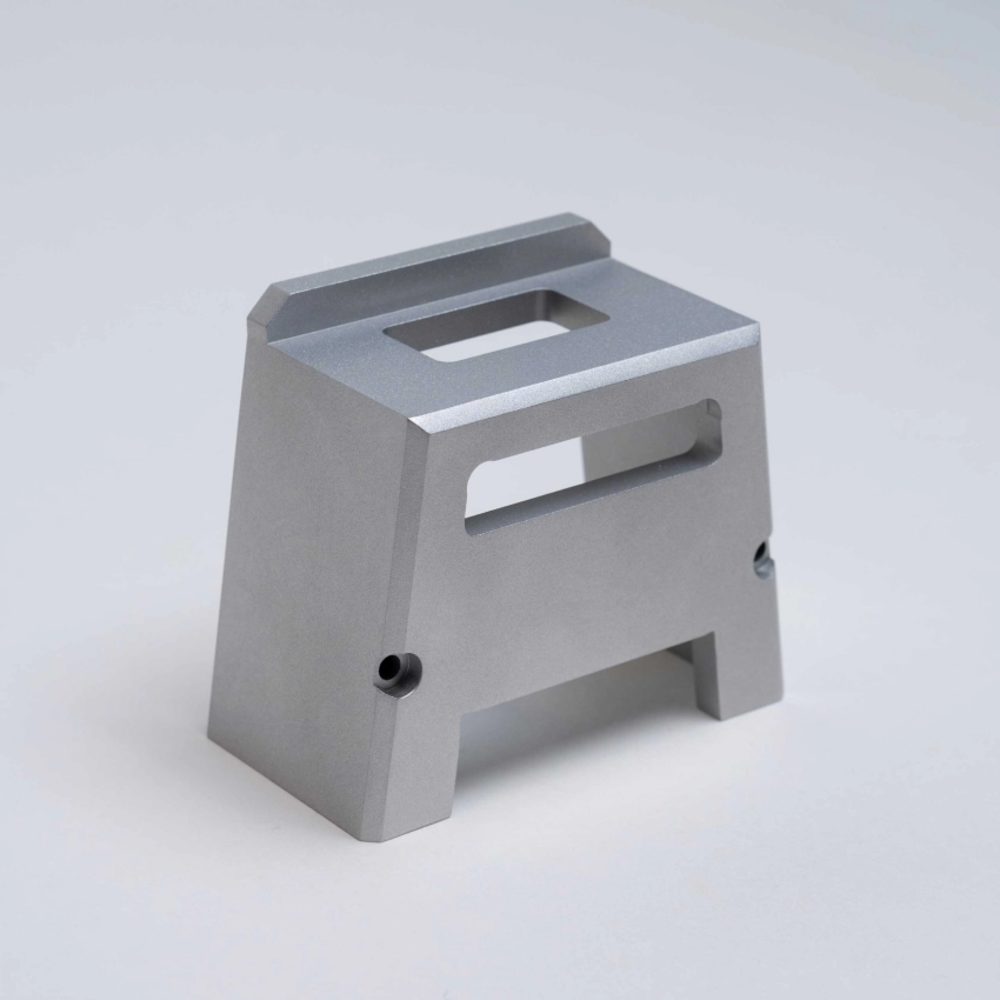

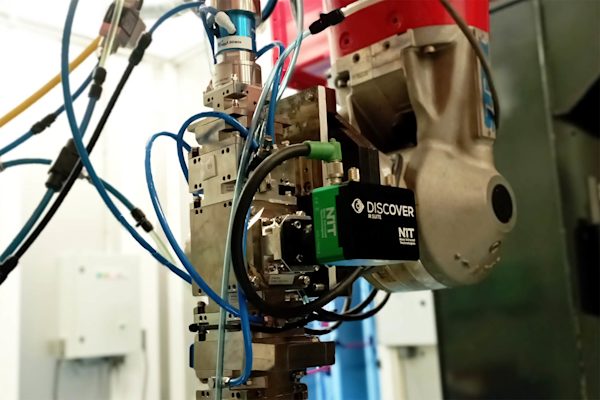

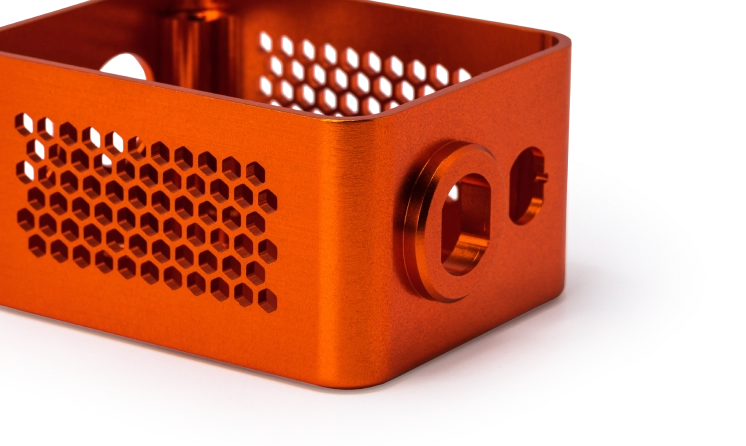

Gallery of CNC machined parts

CNC machined prototypes and end-use parts produced through our network.

Get a quote in seconds

And receive your custom CNC machined parts in days.

Get instant CNC machining quoteOur distributed network

Specialized CNC machine shops around the world

CNC machining case studies

We’ve helped these innovative companies with custom CNC machined parts

FAQs

How much does your CNC machining service cost?

We use machine learning algorithms to calculate the exact cost of any machinable part directly from a CAD file, based on millions of CNC machining orders we’ve previously processed. No more waiting for technicians to get back to you via email, we can generate an exact quote for you instantly (well, in about 5 seconds).

This means you always know the price up front. Simply upload a CAD file to generate a quote: get an instant CNC machining quote. Our quotes are completely free, you only need to create an account so we can protect your IP.

It’s so easy to use that we encourage mechanical engineers to use it constantly as they optimize their designs for cost. Whenever you’ve made a new design iteration, simply load both the old and the new design into our quoting tool and see if the price is different.

This technology means our manufacturing partners also don’t need to do their own machining quotes, which means less overhead for them. This makes the whole process less expensive, which translates into lower prices for our customers.

How can I reduce the cost of my machined parts?

The main costs associated with CNC machining can be grouped into machining time, start-up costs, material costs, and feature costs. To reduce costs you need to understand the impact of these factors on cost.

The best way to reduce machining time is to design features that can be machined quickly, for example by choosing the correct radii for internal corners, reducing cavity depth, increasing wall thicknesses, limiting thread length and designing holes with standard sizes.

Material costs can be reduced by considering the size of the blank required, and the cost and machinability of the bulk material (softer alloys are faster to machine).

Start-up costs can be reduced by reducing the number part rotations or repositioning required to finish the part, for example by separating geometries into multiple parts that can be assembled later.

Feature costs can be reduced by only using tolerances when strictly necessary, removing all text & lettering, and avoiding multiple surface finishes.

These tips can be read in more detail in our full guide to reducing the cost of CNC machined parts.

How do you select the exact manufacturer for my parts?

We use algorithms to identify the best manufacturer in our network for your specific order, based on their proximity to you, their experience with similar parts and their available capacity right now. This allows us to balance our customers’ demands for speed, cost and quality better than ever before.

How do you guarantee the quality of my parts?

Your parts are made by experienced CNC machining shops within our network. All facilities are regularly audited to ensure they consistently meet our quality standards.

Protolabs Network is ISO-9001 certified and additional certifications are available through our manufacturing partners.

Find out more about our quality assurance measures.

Where can I learn more about CNC machining?

Protolabs Network was started by mechanical engineers and we have many more engineers and technicians in our team. Together we’ve written a lot of content on CNC machining over the years. You can find a selection of resources below, or you can head to our knowledge hub and filter on CNC machining to read case studies, in-depth design guidelines and explanations of different surface finishes.

We’ve also written a complete engineering guide to CNC machining. Here you can learn about how the many different kinds of mills and lathes work and the different materials available, so you can easily compare their benefits & limitations. You’ll also learn the basic design rules for machining and the most common applications of each material and surface finish, so you can make the right choices every time.

Put your parts into production today

Get instant quote