Chromate conversion coating services

Chromate conversion coating, more commonly known as chem film or by its brand name Alodine, is a type of conversion coating, used on aluminum as a corrosion inhibitor, as a primer for paint due to increased adherence or to preserve electrical conductivity.

| Surface preparation | Colors | Applicable materials | Thickness | Cosmetic availability | Visual appearance |

|---|---|---|---|---|---|

| As machined (Ra 3.2μm / Ra 126μin) | Clear/ slight yellow tint | Aluminum (7xxx series not recommended) | None | No | Machining marks are visible |

| Bead blasted (Glass beads #120) | Clear/ slight yellow tint | Aluminum (7xxx series not recommended) | None | Cosmetic on request | Machining marks are completely removed on “cosmetic” parts but may be visible on “non-cosmetic” parts |

Example of chromate conversion coated parts

Design considerations for chromate conversion coating:

-

When applying chromate conversion coating, the dimensions of the part can be controlled, enabling it to maintain the requested tolerances.

-

Chromate conversion coating can be applied to aluminum alloys, however, steel and iron parts cannot be coated directly.

What is chromate conversion coating?

Chromate conversion coating is a chemical coating for metal that has many benefits. It protects aluminum from corrosion, serves as a primer for painting and preserves electrical conductivity, making it a useful finish for parts used in the aerospace, automotive and construction industries. At Hubs, we only use chromium-free, RoHS-compliant chromate conversion coating.

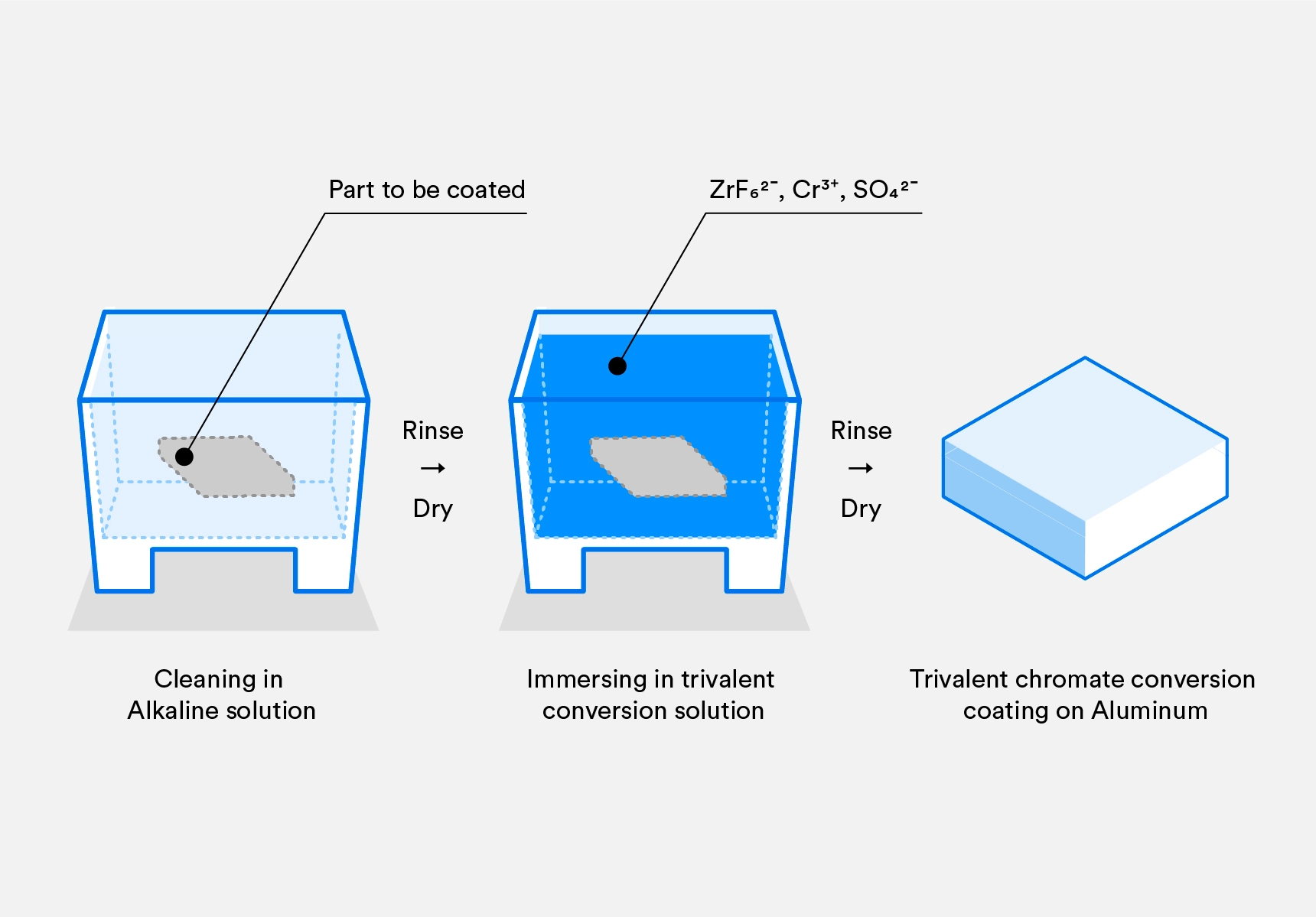

How does chromate conversion coating work?

Chromate conversion coating involves adding chromic acid to a metal in a chemical process that results in a thin, protective outer layer. This enhances a metal’s durability and makes it more resistant to corrosion.

Protolabs Network offers chromate conversion coating for aluminum parts to improve functional properties. To find out more, contact networksales@protolabs.com.

Here’s how we apply chromate conversion coating:

-

Parts are cleaned and degreased to remove any contaminant

-

Parts are then rinsed to eliminate any residue of detergent

-

Aluminum parts are immersed in a tank containing the chemical solution

-

Parts are removed when a film of the desired thickness coats the surface

-

Parts are then rinsed again

Put your chromate conversion coated parts into production today

Get instant quote