With bead-blasted finishes, tight tolerances, and designs that are almost completely free of straight edges, Hone Shaving’s razors might seem to be manufactured as single pieces.

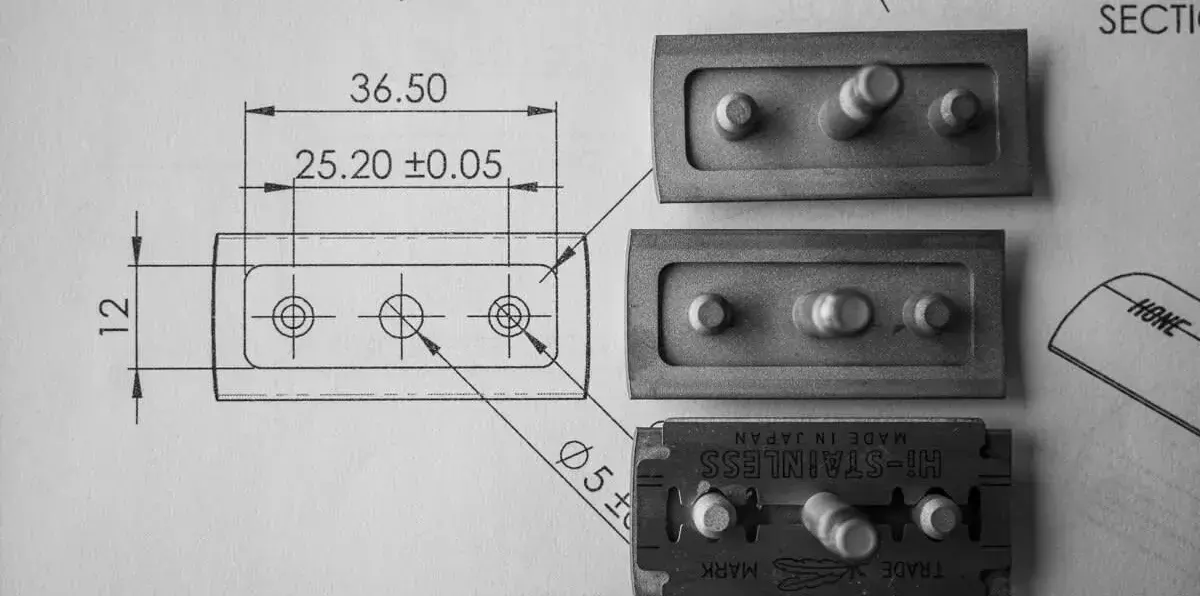

Their appearance, however, belies their intricacy; there are through holes, blind holes, thin slots, curves, and sophisticated internal assemblies. They are also three-piece units, consisting of a top cap and a guard bar–between which a straight razor is sandwiched–as well as a handle.

Hone Shaving’s razors are iconic heirloom pieces that are built to last for years upon years. There’s a personal reason behind the product’s inception. “The reason I started Hone was a loss in my family, and I was left with an object from that person,” Andrew Mitchell, Hone Shaving’s founder and sole proprietor, says.

A complex CNC machining process

“There’s a saying in design: ‘The simpler you go, the more complexity you have to hide’,” “That’s true of my product. I’m asking some quite challenging things of machined parts.”

Take the handle and guard bar, which must be fitted together in such a way that users can’t feel the split line between them when gripping the razor’s handle. Or the finishing on the top cap, which must provide some grip, but not so much as to prevent a smooth shave.

They are CNC-machined out of stainless steel, aluminum, and bronze, striking a fine balance between quality, finish, and price – and with profit margins that are, perhaps unsurprisingly, razor-thin.

Suitable for small or large volumes

“Previously I was dealing directly with CNC shops to manufacture them,” Mitchell said. “But a lot of the bigger manufacturers often don’t want to take on a job of machining a few hundred to a thousand pieces like this, especially from a demanding customer.”

There’s also the issue of bandwidth, Mitchell said. As a small company making a low-volume product, Hone Shaving doesn’t have much wriggle room if and when things go wrong. Run out of machine time or budget with a traditional machining shop, and your run is over, regardless of whether you’ve achieved the quality you desire.

Some of the machine shops Mitchell previously worked with tried unsuccessfully for more than a year to manufacture the parts he needed, leaving him feeling backed into a corner. Then things got worse.

“I had a manufacturer go into liquidation halfway into a production run that I’d already paid for,” Mitchell said. “I lost an entire production batch and the costs associated with it. The next one had to work, or I would have been in a troubled place with my business. The Protolabs Network team dug me out of a hole.”

Within two months of work with Protolabs Network, Mitchell was holding samples of the razors in hand. Three months after that, he had the final product.

Personal service from knowledgeable experts

“I was able to leverage Protolabs Network’s scale and have personal contact with someone,” he said. “They were able to find the right manufacturers to meet the requirements I was looking for. Doing that myself would have involved emailing 10, 15, 20 machine shops and hoping for the best.”

Additionally, the samples Mitchell requested were staggered across production runs, offering him reassurance that the razors were being manufactured with as much precision as the shaves they would eventually provide his end customers.

“Everyone at Protolabs Network takes me seriously. They are super professional. It doesn’t matter that I’m an individual; I’m treated with the same care as a larger organization,” he said. “Quotes come back quickly, emails are replied to the same day, people keep their appointments. I never feel like a lower-class citizen because I am a single-person company.”

That resonates with him. Hone Shaving’s razors are Mitchell’s interpretation of a daily task that is as ritualistic as it is habitual. They are art, in a way – infused with a level of care that is not only demanded by his customers, but which comes from his genuine intention to create a high-quality, long-lasting, and meaningful product.

“If I skimp on the quality, fit, or finish, then it isn’t €200 worth of value to someone,” he said. “You’re buying that person’s expression of something and the attention that they put behind it.”