3D printing is an optimal manufacturing method for producing prototypes and even certain end-use parts. It’s often the most cost-efficient option and delivers tremendous value, depending on the specific technology you choose.

There are many different categories of 3D printers and within those many different types of commercial and industrial printers. This article covers the main types of 3D printers and what they're capable of producing.

Understanding the complex landscape of 3D printing will help you when it comes time to manufacture the parts you’ve designed and save you a lot of time and considerable funds. So, let’s get started.

Want to explore our 3D printing capabilities?

What are the different types of 3D printers?

In 2015, the ISO/ASTM 52900 was created to standardize how 3D printers and 3D printing technology are classified. A total of seven process categories were established.

-

Vat polymerization: liquid photopolymer (resin) cured by light

-

Material extrusion: molten thermoplastic (filament) deposited through a heated nozzle

-

Powder bed fusion (PBF): powder particles fused by a high-energy source

-

Material jetting: droplets of liquid photosensitive fusing agent deposited on a powder bed and cured by light

-

Binder jetting: droplets of liquid binding agent deposited on a bed of granulated materials, which are later sintered together

-

Direct energy deposition: molten metal simultaneously deposited and fused

-

Sheet lamination: individual sheets of material cut to shape and laminated together.

Each technological umbrella comprises many different types of technologies and printers. The processes we offer at Protolabs Network are Stereolithography (SLA), Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS) and HP's Multi Jet Fusion (MJF).

What is vat photopolymerization and how does it work?

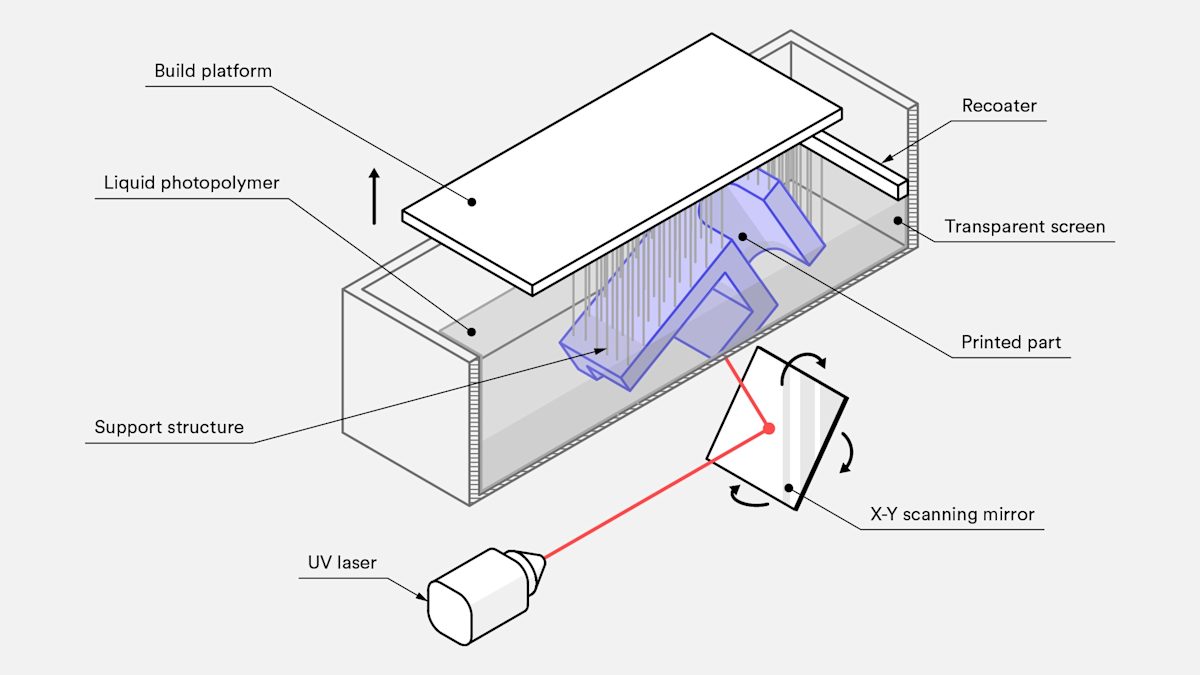

Vat photopolymerization produces parts by selectively curing liquid photopolymer resins with a UV light source. A build platform is submerged in a tank that is filled with resin. The light is selectively directed across the resin surface with mirrors.

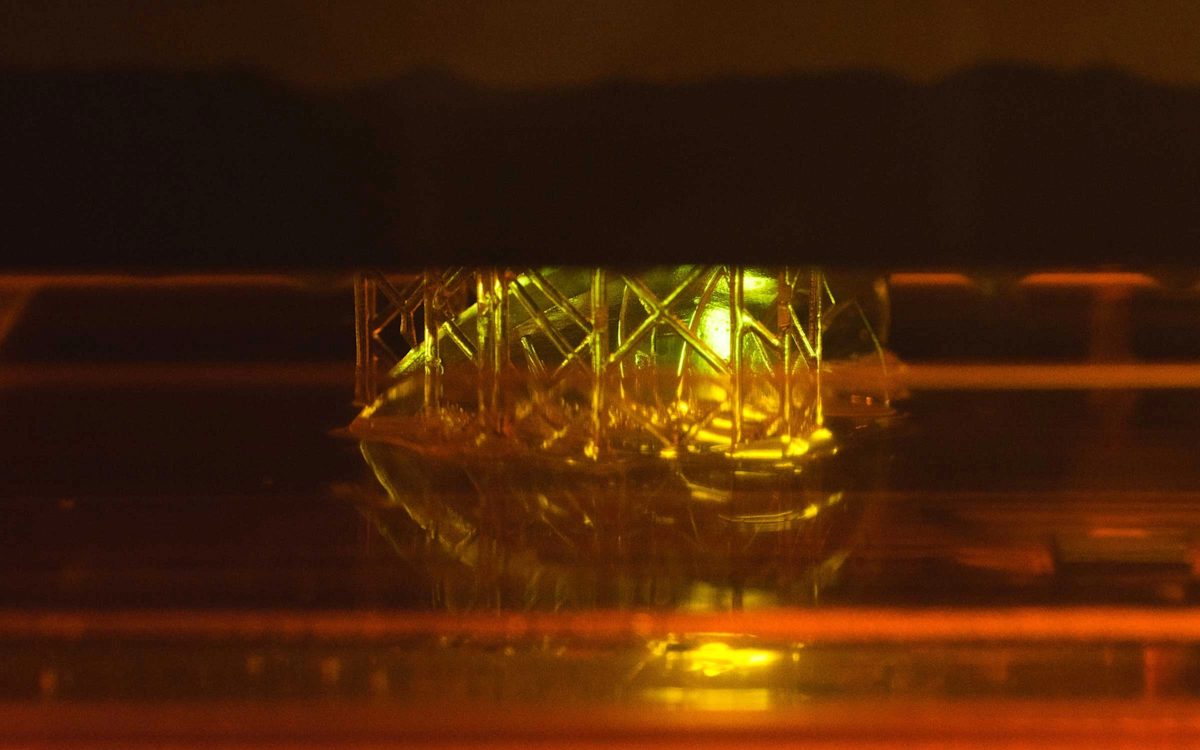

Once a layer is cured, the platform is raised or lowered in a small increment to allow new liquid to flow. The next layer is then cured and adjoins the previously cured one. After the final layer is cured, the print is removed from the resin. At this stage, it is fully formed though can be strengthened with further curing in a UV oven.

Types of vat photopolymerization 3D printers

Vat photopolymerization has a few distinct printing technologies. The three most common are SLA, direct light processing ( DLP) and continuous liquid interface production (CLIP). They are very similar in terms of how a light source directs light at the resin. Overall, SLA is the most common and widely used among printers in the vat photopolymerization family.

Let’s break down the different types of photopolymerization 3D printers:

-

SLA uses a single-point laser to trace a thin line along the surface of the resin, filling in the shape of the cross-sectional layer to be cured. It is highly accurate but can be time-consuming.

-

DLP uses a digital light projector to flash a single image of an entire layer all at once. This makes it faster than SLA. However, because the projector is a digital screen, the image of each layer is composed of square pixels, resulting in a slightly lower resolution.

-

CLIP is the same as DLP except that the build platform moves in a continuous motion. This allows for even faster build times and smoother contours along the z-axis.

Materials for vat photopolymerization

All vat photopolymerization printers use photopolymer resins, most of which are proprietary. There are many different kinds available, including standard resins for general-purpose prototyping. Other common types include tough ABS-like resins, flexible rubber-like resins, transparent castable resins with zero ash content after burnout, ceramic-filled resins for very rigid prints and biocompatible resins for medical devices.

Some resins, including transparent ones, require additional post-processing to achieve the best visual results or, in the case of clear resins, optical clarity. If you’re opting for SLA for your custom parts, check out our comparison of different SLA 3D printing materials.

Geometric properties of vat photopolymerization

Build volumes vary a lot between desktop SLA and industrial SLA printers, but are typically smaller than those of FDM or PBF. They print a maximum of about 300 mm in any one dimension. Vat photopolymerization machines can print highly complex parts, though not as complex as those achieved by PBF due to the need for support structures.

What it lacks in build volume and complexity, vat photopolymerization makes up for in the print resolution, as these machines can print incredibly fine details.

Mechanical properties of vat photopolymerization

Vat photopolymerization printers produce parts with very tight tolerances and can allow for consistent repeatability. If parts are fully cured after printing, they can also be fully isotropic. But where this technology truly shines is in surface finishing. Vat photopolymerization can print extremely smooth contours, comparable to what injection molding can achieve.

Another major advantage over other technologies is that fully cured parts can be made watertight and airtight. However, the curing process is irreversible, so heated parts burn instead of melt.

Are vat photopolymerization printers fast and cost-efficient?

Vat polymerization is the oldest type of 3D printing, with the earliest SLA printers dating back to the 1970s. Competition between printer manufacturers continues to drive prices down, but it remains expensive, costing around the same as plastic powder bed fusion (PBF). These machines are cheaper than those for SLS, but the material is more expensive.

Many factors affect print times, but vat polymerization is generally considered one of the fastest technologies.

Commercial applications: what can you produce with vat photopolymerization?

The wide range of available materials gives vat photopolymerization processes an equally expansive range of applications, from prototyping to end-use parts.

High resolution and tight tolerances make the technology ideal for jewelry, low-run injection molding and many dental and medical applications. Being able to print watertight parts makes vat photopolymerization popular in the automotive, aerospace and healthcare industries. As well, smooth surface finishes make it optimal for prototyping injection-molded parts.

What is material extrusion and how does it work?

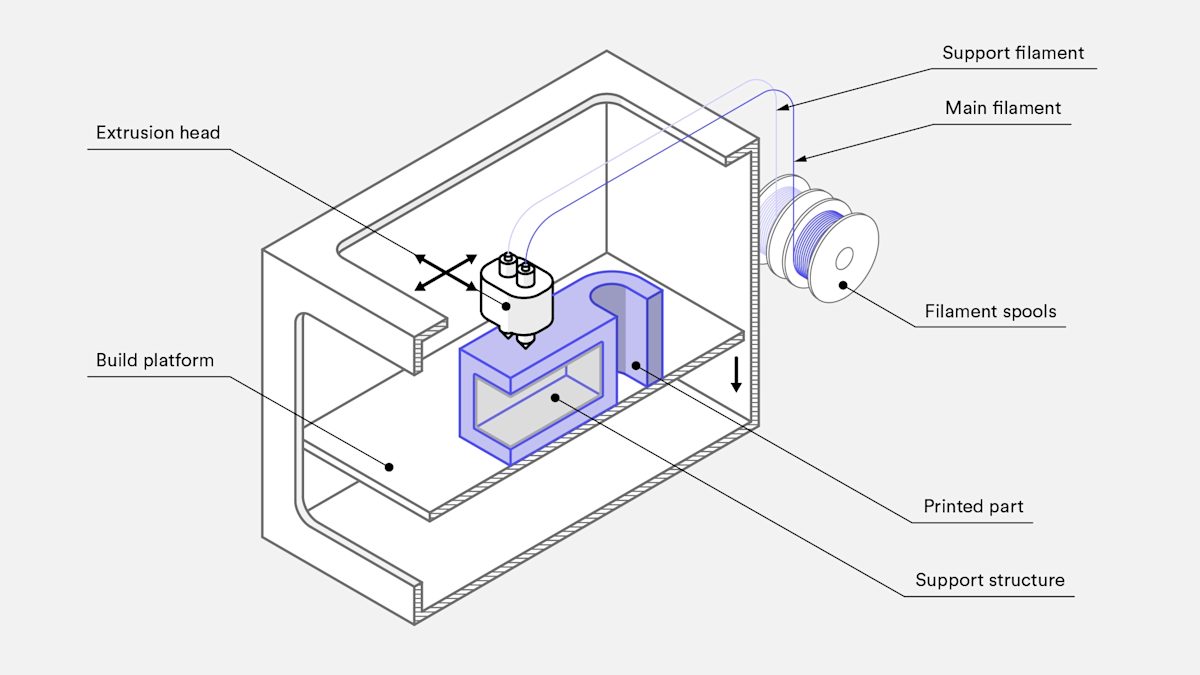

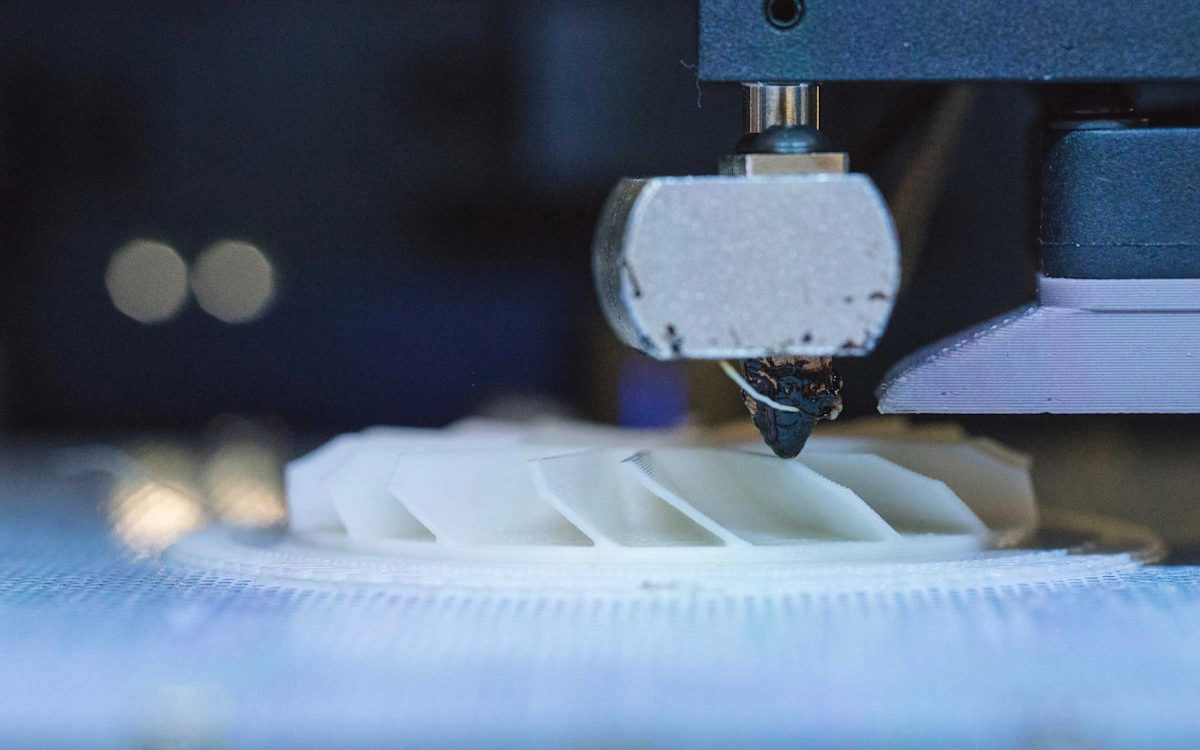

Material extrusion produces parts by printing layers of molten thermoplastic filament one on top of the other. A spool of filament is fed through a heated extrusion nozzle and melted. Printers continuously deposit melted filament at precise locations, where it cools and solidifies. Picture an automated hot glue gun methodically moving over a flat build surface.

The printer nozzle can move along three axes in relation to the build platform. It traces the shape of a single cross-section of the print along the x- and y-axes, layering cross-sections on each other along the z-axis to build up the full print.

Types of material extrusion printers

Fused deposition modeling (FDM) and fused filament fabrication (FFF) are the two types of material extrusion printing technologies. Material extrusion is relatively simple and is by far the most cost-efficient and widely available printing technology on the market.

The two main types of FDM are prototyping (desktop) and industrial. We differentiate between the two because, although the technologies are virtually identical, the scale of each is vastly different.

Materials for material extrusion

Because FDM is so widely used, thousands of different filaments have appeared on the market. By far the most common are ABS and PLA, but Nylon, PC, PETG, TPU and PEI are also available. Certain filaments also come reinforced with fibers, such as carbon, Kevlar, fiberglass, wood and metal.

For more information on how to choose the right filaments for your job, we wrote a guide comparing different FDM 3D printing materials.

Geometrics properties of material extrusion and FDM

There are thousands of brands of FDM printers, coming in all shapes and sizes. The largest have build platforms of about 1,500 mm in all dimensions, while the smallest can easily fit on your desk next to your espresso machine.

Because parts are built from the bottom up, certain features, such as overhangs, require supports built along with the actual part. This being the case, FDM isn’t always the ideal solution for printing more complex components.

The resolution is a function of the filament, with the thinnest filaments being around 0.15 mm thick. The fact that filament is round means that sharp corners cannot be printed and walls are never flat unless processed after printing.

Mechanical properties of material extrusion and FDM

FDM printers are generally not used for producing functional end-use parts, though there are a few exceptions here and there. They are not the most accurate 3D printers, as the parts they print are weak along the z-axis. Parts also have very clear layering on every surface.

Are material extrusion and FDM fast and cost-efficient?

FDM printers are known for being lower tier in terms of cost, with desktop machines costing between $500 and $5,000. Industrial grade machines, on the other hand, can be way more expensive and far out of the financial reach of even the most dedicated hobbyists.

Material extrusion machines are cheap to own and easy to run, but outsourcing is equally popular because the ubiquity of the technology makes one-day lead times common practice.

Standard FDM materials are widely available and competition keeps prices down. Printing times are fast for single parts but, unlike vat photopolymerization or PBF, there are no economies of scale. That makes FDM relatively slow for high-volume runs, and likely not the best value for a vast number of parts.

Commercial applications: what can you produce with material extrusion and FDM?

While FDM parts are not as durable or cosmetic as components made using other techniques, they are highly cost-effective. These characteristics make FDM the most commonly used technology for many stages of prototyping, especially early on in the proof of concept stage.

FDM’s variety of available materials, speed and cost-effectiveness also make it very attractive for certain types of production parts as long as the resolution and surface finish are not critical factors. Industrial FDM printers can easily produce functional prototypes and end-use parts from robust materials, such as grips, jigs and fixtures. Producing these latter components with FDM machines is preferable to traditional manufacturing in terms of price.

What is powder bed fusion (PBF) and how does it work?

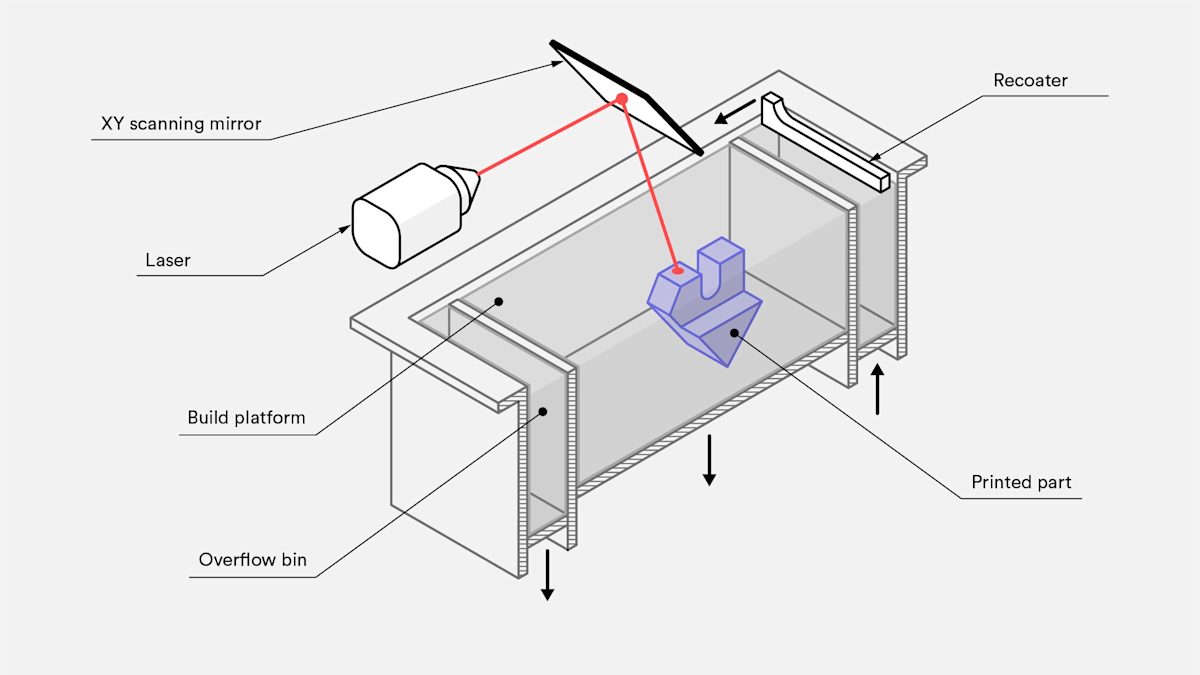

Powder bed fusion printers produce parts by selectively melting or sintering powdered particles together to form a whole object. The powder material is heated to just below its melting point and spread over the build platform in a very fine layer. A laser or electron beam is then directed across the powder’s surface, fusing particles together to form a single cross-section of the print.

After each layer, the build platform is lowered and the process repeats. Each new layer is fused to the previous until all the layers have been fused into one object.

As layers are built on top of one another, the unfused particles act as a support structure for the print, thereby eliminating the need for most separate support structures. Once the print is complete, the excess supporting powder is removed and recycled.

Types of PBF printers

Lots of 3D printers use PBF technology. The most common types of printers are selective laser sintering ( SLS), direct metal laser sintering (DMLS), selective laser melting (SLM), HP’s Multi Jet Fusion ( MJF), high-speed sintering (HSS) and electron beam melting (EBM). SLS is the most common for plastics, and DMLS and SLM are the most common for metals.

-

SLS printers produce solid plastic parts using a laser to sinter particles together.

-

DMLS printers create porous metal parts using a laser to sinter particles together.

-

SLM printers produce solid metal parts using a laser to melt particles together, not just sinter them. Since this is only possible when the particles have the same melting point, SLM can only print in single metals, not alloys.

-

MJF produces solid plastic parts through a combination of SLS and material jetting technologies. After a layer of plastic powder is spread over the build platform, a printhead with inkjet nozzles selectively deposits agents that encourage and inhibit fusing. A high-power infrared beam then passes over the layer, fusing only areas where the fusing agent was dispensed.

-

EBM produces solid metal parts using an electron beam to melt particles together, but parts must be produced in a vacuum. The process can only be used with conductive metals.

-

HSS uses an inkjet print head to deposit an infrared-absorbing fluid directly onto a thin layer of plastic granulate that’s spread across the heated surface of a build platform, outlining the area where sintering is desired. Infrared light is then used to fuse the powder under the fluid into a layer.

-

MJF uses an inkjet array to selectively apply fusing and detailing agents across a bed of nylon powder, which are then fused by heating elements into a solid layer.

Materials for powder bed fusion

SLS prints in plastics and nylon composites, such as Alumide, which is a combination of nylon and aluminum. Polypropylene, a thermoplastic polymer, is also growing in popularity for both SLS and MJF.

While materials continue to evolve for SLS, nylon is still the most common material used. There are dozens of different nylons available, but PC, PEEK, PEKK, flexible TPUs, and composite and reinforced nylons are becoming common. Parts are usually printed in white and can be dyed any color.

MJF can only print in nylon. Because the fusing agent is black, in the past, parts could only be printed in gray. Today, however, HP Jet Fusion 500/300 series printers can print parts in full color and white. This series is being phased out but will still be supported for years.

Geometric properties of powder bed fusion

PBF printers can be manufactured larger than those for vat photopolymerization, but even large PBF printers rarely exceed 300 to 400 mm in any dimension. These printers can also print parts in high resolution. Because unused powder acts as a support material as print layers are built up, PBF can produce parts from very complex digital models.

Potential complexity is the same for MJF and SLS, with both achieving better results than SLA. However, SLA has even higher resolution (its layer height can go down to 25 microns whereas SLS always prints at 100 microns and MJF at 80 microns). MJF can produce slightly better resolutions than SLS, but SLS offers a broader range of materials

For metal, DMLS can print parts with some of the highest resolution available, followed by SLM and then EBM.

Mechanical properties of powder bed fusion

PBF can produce tolerances on par with vat photopolymerization, but PBF parts are much stronger. PBF can produce functional plastic parts with the best mechanical properties any 3D printing technology is capable of. MJF prints are slightly stronger than SLS and also have a smoother surface finish.

EBM systems produce less residual stresses than DMLS and SLM, resulting in less potential distortion. The metal parts made by DMLS are not as strong as those by SLM, since the powder particles are only sintered and parts remain slightly porous. However, SLM parts can have mechanical properties on par with traditional manufacturing technologies such as machining and forging.

All PBF prints have a slightly rough finish due to being made from powders, though can easily be polished smooth with simple post-processing.

Is powder bed fusion fast and cost-efficient?

PBF market competition continues to drive prices down, but it remains expensive. For metal 3D printing, it is still extremely expensive, usually costing more than CNC machining. For plastics, the cost is comparable to vat photopolymerization. MJF is usually around 10 percent cheaper than SLS.

When it comes to low volumes for plastics, SLS and MJF are slower than vat photopolymerization and FDM. However, they are the fastest for large batches because parts get printed directly on the build platform.

Commercial applications: what can you produce with powder bed fusion?

The ability to produce strong functional parts makes PBF the preferred technology for producing low volumes of functional plastic parts across all industries. Common applications include one-off industrial hardware such as machine parts, jigs, grips, and fixtures as well as low-volume production runs of customized plastic components.

Because of how expensive they are, DMLS, SLM, and EBM are only used when a part’s geometric complexity is too expensive to be machined or surpasses what machining can produce. Being able to produce very complex parts makes PBF the go-to technology for rapid prototyping.

What is material jetting and how does it work?

Material jetting produces parts by jetting tiny droplets of a liquid material onto the build platform and solidifying them with heat or light. Much like the standard 2D ink jetting process, a printhead with hundreds of material jets moves over a build platform, depositing material along an X-axis carrier, sweeping back and forth like the windshield wipers on a car and covering one whole layer in a single pass.

One printhead can carry jets for multiple materials, allowing for multi-material printing, full-color printing, and dispensing disposable support structures, such as wax.

Types of material jetting 3D printers

Within the material jetting category there are a few distinct printing technologies. The three most common are PolyJet, NanoParticle Jetting (NPJ), and Drop-On Demand (DOD). As of mid-2022, PolyJet is by far the most popular.

-

PolyJet, the first material jetting technology, is patented and owned by Stratasys. This kind of printer dispenses liquid photopolymer resin and easy-to-remove support material from the printhead, which is then cured by a UV light.

-

NPJ is a technology patented by XJet. Unlike with PolyJet, where each layer is cured before the next is deposited, NPJ prints are cured once all the layers are deposited. Metal or ceramic nanoparticles are suspended in a liquid, which is deposited by the printhead along with support material. Heat in the printer causes the suspension liquid to evaporate as each layer is deposited, leaving only slightly bonded metal or ceramic and supports behind. Once the final layer is complete, the support material is removed and the whole part is sintered to bond all the nanoparticles.

-

DOD is a technology patented by SolidScape (acquired by Stratasys). It is very similar to PolyJet, but was developed specifically for high-precision printing in wax for investment casting and mold making, targeting the jewelry industry. Unlike in PolyJet, the printhead can print curves in high resolution by moving in both x- and y-axes. After the material droplets are deposited, each completed layer is skimmed with a fly cutter to ensure a perfectly flat surface. These factors improve the final dimensional accuracy.

Materials for material jetting

Due to the variety of technologies in the category, a wide range of materials is available for use with material jetting printers. The most common are photopolymers, flexible plastics, casting wax, metals, and ceramics.

PolyJet printers are known for being able to produce full-color, multi-material, multi-texture prints.

Geometric properties of material jetting

Build platforms can get quite large—measuring up to 1 square meter, they are almost as large as those used in FDM. Individual parts can also be very large, filling out the whole print bed. Given that fully solid supports are built up around the part, they can also produce very complex parts.

Mechanical properties of material jetting

Material jetting printers are highly precise and able to produce parts with very high tolerances, although the strength of parts is typically less than what FDM or PBF can achieve. The surface finishes are highly smooth, but there is also an option to print in a matte setting.

Is material jetting fast and cost-efficient?

No matter the printer type, material jetting is actually quite expensive. The materials are expensive and the support structures are printed solid, which means there is a lot of material wastage per part.

Production speeds are comparable with PBF printers.

Commercial applications: what can you produce with material jetting?

Material jetting is an expensive 3D printing technology, but its extremely high dimensional accuracy and smooth surface finishes make it the only viable solution when dimensional accuracy or impressive visuals are critical. This is often the case for highly realistic prototypes, anatomical models, complex and high-precision tooling, jewelry, medical devices, and surgical tools.

Multi-material printing is commonly used for haptic feedback prototypes, for example, a stiff case with flexible buttons.

What is binder jetting and how does it work?

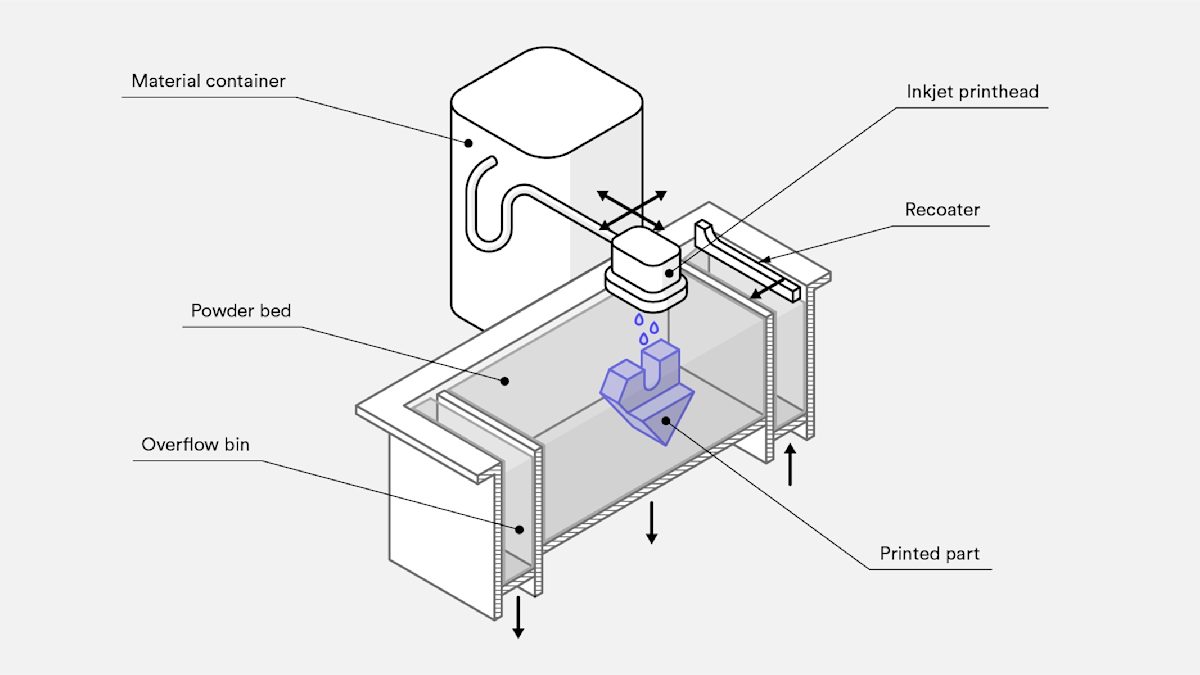

Binder jetting produces parts by selectively depositing a binding agent over a powder bed. The build platform is first covered with a very thin layer of material powder. A printhead covered in inkjet nozzles then passes over, depositing a binding agent where the print is to be formed. Binder jetting printers can also print in color by depositing colored ink after the binding agent, before a new layer of powder covers the previous one.

Once the final layer is finished, the part is left to cure in the powder and let the binding agent gain strength. Once removed from the powder bin, some kinds of materials are ready. However, if parts are for functional use, most need to be infiltrated and sintered, causing them to shrink by up to 40 percent.

Types of binder jetting 3D printers

Binder jetting is achieved by only one technology, though there are many different kinds of printers, differentiated by the kinds of materials and binders they can use.

To learn more, read our introductory article on binder jet 3D printing.

Materials for binder jetting

Because prints are held together by a binding agent—as opposed to bonds between particles of the build material—many materials that can be powdered can be printed with binder jetting. The most common materials are sands, ceramics, and metals, though plastics can also be used.

Geometric properties of binder jetting

Binder jetting is best suited for parts smaller than the size of a fist.

Because the unused powder serves as a natural support structure, complex parts are also possible. However, one constraint is that thickness should never exceed 10mm because the filtration may be inconsistent. As well, the resolutions are high, on par with PBF.

Mechanical properties of binder jetting

Binder jetting can produce parts with good tolerances, but the final tolerance can be hard to predict since shrinkage occurs with post-processing.

Before infiltration, metal parts are extremely weak and can crumble if not handled carefully. After infiltration, they are close to fully dense, but their mechanical properties do not meet the higher quality of traditionally manufactured parts.

The surface roughness of these metal parts is better than that achieved with DMLS and SLM.

Is binder jetting 3D printing fast and cost-efficient?

Binder jetting is an affordable technology, costing even less than vat photopolymerization and PBF. Print speeds are comparable to PBF and in line with other technologies for low-volume runs, but fast for higher volumes.

Commercial applications: what can you produce with binder jetting?

Because it can produce complex parts quite quickly and cost-effectively in a variety of colors, binder jetting is ideal for full-color prototyping. The price point of binder jetting is lower than material jetting and, despite its mechanical-property limitations, it can still achieve resolutions suitable for most prototypes.

This is also one of the fastest and most affordable techniques for producing complex, high-precision metal and ceramic parts. Many different powders are available, and print beds can be relatively large. The mechanical properties of binder-jetted metal parts do not match the strength or tolerances of PBF prints but they can still be functional if infiltrated and sintered.

Binder jetting is especially attractive for producing complex casts from sand because it can print large, complex geometries at a relatively low cost. And the process is simple enough to be integrated with most traditional foundry processes.

Ready to select the right 3D printing method for your custom parts?

Learn how to choose the perfect technology Check out our online 3D printing services

What is direct energy deposition and how does it work?

Direct energy deposition (DED) produces parts by layering beads of molten material, which is usually metal. The technology is very similar to that used in plastic material extrusion printers, but for metal. The feedstock material, which is either powder or wire, is continuously pushed through a nozzle and melted by a laser or an electron beam or arc at the point of deposition, where it cools and solidifies.

The nozzle can move along multiple axes in relation to the build platform. Three-axis machines trace the shape of a single cross-section of a print along the x-axis and y-axis, layering cross-sections on one another along the z-axis to build up the full part. Five-axis DED printers are not limited to building up parts layer by layer because they can deposit material from any angle. This means they can do more than simply build up parts from scratch and are often used to deposit material on multiple sides of existing objects.

DED is often referred to as direct metal deposition (DMD). There are also many different proprietary technologies whose names are often used interchangeably, even though they differ in their materials and energy sources.

All work according to very similar principles. Laser Engineered Net Shaping (LENS) by Optomec is the best-known example of a technology that fuses powders with a high-powered laser. Electron Beam Additive Manufacturing (EBAM) by Sciaky is the best-known example of a technology that fuses extruded wire with an electron beam.

Types of DED printers

LENS utilizes a deposition head consisting of a laser head, powder dispensing nozzles, and inert gas tubing. The laser travels through the center of the head to create a melt pool on the build area and powder is sprayed from the sides where it is melted and then solidified. The inert gas forms an oxygen- and moisture-free shroud, which prevents surface oxidation and promotes better layer adhesion.

EBAM feeds metal welding wire through the nozzle and melts it with an electron beam at the contact point with the build area. Essentially, EBAM is FDM for metals.

Materials for DED

LENS technology can print in both metals and ceramics, although ceramics are by far the more common material in use. Available materials for both LENS and EBAM include almost any weldable metal, such as aluminum, steel, titanium, Inconel, tantalum, tungsten, nickel, and niobium.

Geometric properties of DED

Another key advantage of DED is the very large print bed sizes. It is not uncommon for large manufacturers to build customer DED printers with build envelopes that are multiple meters long along any dimension.

Support structures are possible but difficult because the large liquid melt pool at the deposition point does not allow for overhangs. The same attribute means complex geometries are also not possible. Resolution is very poor compared with other metal 3D printers. Powder particle sizes are between 50 and 150 microns and welding wire ranges from 1 to 3mm in diameter.

Sharp corners, for example, can only be achieved in post-processing, typically by a CNC mill. This is very common practice, as new material is built up with DED and then machined to the desired precision.

Mechanical properties of DED

The high amount of energy required to maintain a melting point at the point of deposition creates large thermal gradients that can cause a lot of residual stress, but DED produces fully dense parts with mechanical properties that are as good as forged metal parts.

The low resolution, however, means parts tend to have a poor surface finish, requiring secondary machining to achieve the most desired results.

Is DED fast and cost-efficient?

The two most important advantages of DED are print speed and material cost. All DED technologies are relatively fast at laying down material, with the fastest machines printing 11kg per hour, (albeit with very low resolution). The metal feedstock used is also cheaper than that used by other metal 3D printers.

The powders are usually commercial off-the-shelf (COTS) materials designed for welding and are widely available. But for simple parts, traditional manufacturing is still almost always cheaper.

Commercial applications: what can you produce with DED?

The three main applications of DED are part repairs, feature additions, and near-net-shape part production. Essentially a form of welding, DED can print onto existing parts. This makes it ideal for repairing broken parts and adding features that cannot be added via other processes. Tool repair is by far the most common use, and companies turn to DED when expensive machinery proves more cost-effective to fix than reorder, such as in heavy industry.

Because the resolutions are so low, most parts also require post-processing with a CNC mill. Parts are therefore printed near to net shape, with the expectation that they will be machined to proper tolerances. Because conventional manufacturing is almost always cheaper, near-net-shape DED printing is only used when traditional manufacturing is very slow, expensive, or simply not possible.

What is sheet lamination and how does it work?

Sheet lamination produces parts by stacking and laminating sheets of material cut to match a part’s single-horizontal cross-sections. In some printers, the sheets are first cut and then laminated. In most, the sheets are first laid and laminated and then cut to size.

Types of sheet lamination printers

This is one of the simplest methods of building up 3D models. Despite its simplicity, there are many different proprietary technologies based on material, lamination method, and cutting method. In most cases, the process is a simple variation of paper laminated object manufacturing (LOM). Ultrasonic consolidation (UC) is the only radically different technology, as it uses ultrasonic welding rather than a separate bonding agent.

-

LOM laminates sheets together with a bonding adhesive and then subtracts features layer by layer, using CNC milling, laser cutting, or water-jet cutting.

-

UC follows the same process at LOM, except the lamination is achieved through ultrasonic vibrations as a form of friction welding.

Materials for sheet lamination

Across all the different types of printers, there are many available materials: papers, most polymers, fiber-reinforced polymers, ceramics, and just about any metal. Multi-material layers can also be achieved with all these materials, provided each layer can be laminated and shaped with the same methods.

Using colored sheets enables full-color prints across the color spectrum.

Geometrics properties of sheet lamination

Sheet lamination print beds vary quite a lot in size, but are comparable to SLA and SLS printers. Large-format printers are not common.

Because the sheet cutting methods are relatively simple, highly complex shapes are not possible. However, because support structures are not necessary, internal structures are possible.

One additional design option is to lay embedded wiring between sheets. Most processes do not require heat, so expect a reduced risk of high temperatures destroying them. Typical layer resolution depends entirely on the material feedstock

Mechanical properties of sheet lamination

Dimensional accuracy and surface finishes are on par with what can be achieved with a simple CNC milling machine, laser cutter, or water-jet cutter. The weakness of the bond between sheets, however, means that these parts are unsuitable for structural or functional purposes.

Is sheet lamination fast and cost-efficient?

LOM is very cost-effective thanks to the ready availability of all the raw materials. The lack of pre-production preparation means the printers are also very fast.

What are the commercial applications of sheet lamination?

LOM was originally used in architecture for building models. Today its most common use is for highly detailed, colored objects, typically for proof-of-concept and look-and-feel prototyping.

Ready to start 3D printing custom parts?

Frequently asked questions

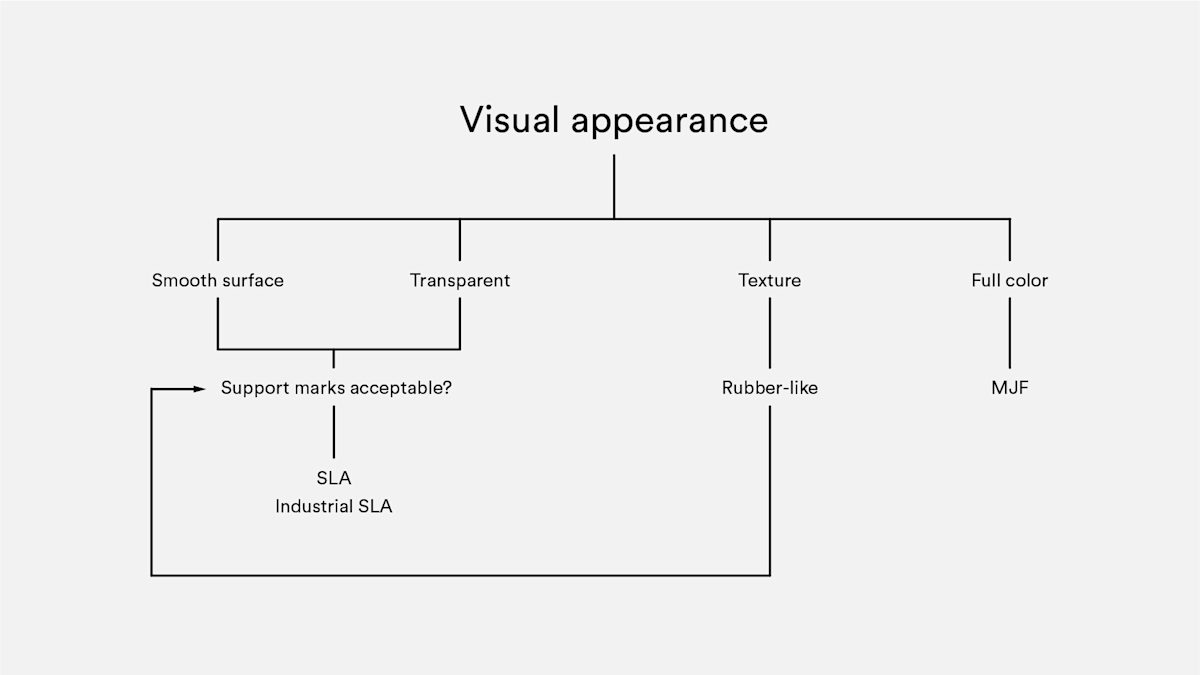

How do I decide the right 3D printing technology for my custom parts?

There are many factors to think about before settling on the right 3D printer for your manufacturing needs. These include functionality, materials required, cosmetic characteristics, process capabilities and many more. To start, check out this comprehensive resource on selecting the right 3D printing process, and remember that you can (and should) always test different printing methods before finding the one that's perfect for your custom parts.

What 3D printer is optimal for complex geometries.

What do I do if several 3D printers work for my custom parts?

Oftentimes, several different 3D printing processes can produce your parts. If this ends up being the case, compare the cost and properties of each to determine the right manufacturing fit.

What 3D printing technology is right for functional polymer parts?

What 3D printing technologies will give me the best cosmetic appearance?

For the best cosmetic quality, thermosets (SLA/DLP or material jetting) will give you the most impressive aesthetics.

What's the best 3D printing technology for metal parts?

Honestly, we recommend pivoting to CNC machining for producing metal parts, though if your designs are very complex, DMLS and SLM are viable alternatives to milling and turning.