Manufacturing parts for production, also known as end-use parts, refers to the process of using raw materials to create a component that is designed and produced for use in a final product rather than as a prototype or model. Check out our guide to manufacturing initial prototypes to learn more about this.

To ensure your parts perform in real-world applications such as machinery, vehicle components, or consumer products, manufacturing must be planned with end-use conditions in mind. Material selection, part design, and production methods should be evaluated to meet functional, safety, and quality requirements efficiently.

Selecting materials for production parts

Common materials for production parts include metals such as steel and aluminum, engineering plastics like ABS, polycarbonate and nylon, composites such as carbon fiber and fiberglass, and select ceramics.

Choosing material for end-use parts depends on the application’s performance requirements, cost and availability. Consider the following material properties when selecting materials for production parts:

-

Strength. Materials should withstand the operational loads the part will encounter. Metals typically provide high strength.

-

Durability. Materials should resist wear and tear over time without degrading or breaking down. Composites offer both durability and high strength.

-

Flexibility. Depending on the application, a material may need to flex to accommodate movement or deformation. Plastics such as polycarbonate and nylon provide good flexibility.

-

Temperature resistance. If the part will be exposed to high temperatures, the material must withstand heat without melting or deforming. Steel, ABS and ceramics are examples of materials with good temperature resistance.

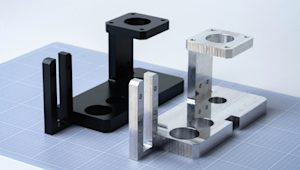

Manufacturing methods for parts for production

Four manufacturing methods are commonly used to produce parts for production: subtractive manufacturing, additive manufacturing, metal forming, and casting.

Subtractive manufacturing

Subtractive manufacturing, also called traditional manufacturing, removes material from a larger workpiece until the desired shape is achieved. It is often faster than additive methods for medium and high volume batch production. However, tooling and setup costs can raise overall expense, and the process typically produces more material waste. For engineers outsourcing production, subtractive manufacturing is often the preferred option for repeatable, high‑throughput parts.

Common types of subtractive manufacturing include:

-

Computer numerical control (CNC) milling. A form of CNC machining that uses rotating cutting tools to remove material from a solid block. It produces high-accuracy parts in metals, plastics, and composites.

-

CNC turning service. A CNC machining method where the workpiece rotates while a cutting tool removes material. It is commonly used for cylindrical parts such as shafts and valves.

-

Sheet metal fabrication. Flat metal sheets are cut, bent, and formed to match a blueprint, typically provided as a DXF or CAD file.

Additive manufacturing

Additive manufacturing, also known as 3D printing, builds parts by adding material layer by layer. It produces complex geometries that are difficult or impossible with subtractive methods, generates less waste, and can be faster and more cost effective for small batches of complex parts. For simple parts, however, additive processes can be slower than subtractive methods, and the available material range is generally more limited.

Common types of additive manufacturing include:

-

Stereolithography (SLA). Also called resin 3D printing, SLA uses a UV laser to selectively cure a liquid polymer resin, building parts layer by layer.

-

Fused Deposition Modeling (FDM). Also known as fused filament fabrication, FDM extrudes melted thermoplastic filament along programmed toolpaths to form the part.

-

Selective Laser Sintering (SLS). SLS uses a laser to sinter polymer powder particles, fusing them into solid layers to build the part.

-

Multi Jet Fusion (MJF). HP’s MJF deposits agents and applies heat to fuse powder selectively, producing parts with consistent mechanical properties and fine feature resolution.

Metal forming

Metal forming shapes metal by mechanical or thermal deformation, using hot or cold processes depending on the alloy and desired geometry. Parts made by forming typically offer high strength and durability and generate less material waste than many other manufacturing methods.

Common types of metal forming include:

-

Forging. Metal is heated and shaped by applying compressive force.

-

Extrusion. Metal is forced through a die to produce a specific shape or profile.

-

Drawing. Metal is pulled through a die to form the required cross section.

-

Bending. Metal is bent to the desired geometry by applying force.

Casting

Casting is a manufacturing process in which a liquid material, such as metal, plastic, or ceramic, is poured into a mould and allowed to solidify into the required shape. It produces parts with good accuracy and repeatability and is a cost effective option for large batch production.

Common types of casting include:

-

Injection molding. Injection molding produces parts by injecting molten material, typically plastic, into a mold. The material cools and solidifies, and the finished part is ejected from the mold.

-

Die casting. Die casting forces molten metal into a mold cavity under high pressure. It is used to produce complex metal shapes with high accuracy and repeatability.

Design for manufacturability and parts for production

Design for manufacturing, or DFM, is an engineering approach that prioritizes producibility during the design phase to deliver parts that are easier and cheaper to make. Protolabs Network’s automatic DFM analysis helps engineers and designers iterate, simplify, and optimise parts before production, reducing lead time, cost, and the risk of defects. Designing with manufacturability in mind improves efficiency across the supply chain and supports more reliable production outcomes.

Tips for using DFM analysis to minimize the costs of your production run

-

Minimize components. Fewer parts reduce assembly time, lower the risk of error, and cut overall cost.

-

Availability. Prioritize manufacturable designs. Parts that match available production methods and standard equipment are quicker and cheaper to produce.

-

Materials and components. Common materials simplify sourcing, reduce cost, and make replacement parts easier to obtain.

-

Part orientation. Choosing the right orientation for production can reduce supports, secondary operations, and cycle time.

-

Avoid undercuts. Designing out undercuts reduces tooling complexity, shortens lead time, and improves final part quality.

The cost of manufacturing parts for production

Striking a balance between quality and cost is key when manufacturing parts for production. Consider these cost-related factors:

-

Materials. The cost of raw materials depends on the material type, its availability, and the quantity required.

-

Tooling. Includes the cost of machinery, molds, fixtures, and other specialized tools used in manufacturing.

-

Production volume. Higher volumes typically reduce cost per part, with strong economies of scale for injection molding.

-

Lead times. Faster turnaround for time-sensitive projects usually increases cost compared with longer lead times.

Get a quote

Get an instant quote to compare pricing and lead times for your production parts.

To create a part meant for production, upload a CAD file to receive a free quote and comprehensive DFM analysis.

You can learn more about manufacturing parts for production on our Knowledge Base, or contact networksales@protolabs.com for personalized advice about your project.

Frequently asked questions

How do you manufacture parts for production?

Parts for production are most commonly manufactured using subtractive manufacturing, additive manufacturing, metal forming, and casting.

What are the benefits of subtractive manufacturing?

The benefits of subtractive manufacturing include high accuracy, repeatable precision, and a broad selection of material options. It also permits machining at lower temperatures, which helps preserve a material’s mechanical strength.

What are the benefits of casting?

The benefits of casting include the ability to produce complex parts with high accuracy and repeatability, making it a cost-effective option for large-batch production.

What are the benefits of metal forming?

Metal forming produces parts with high strength and durability and is a cost effective option for large batch production.

What are the benefits of additive manufacturing?

Additive manufacturing enables engineers to produce complex geometries and customized parts quickly and efficiently.

Is manufacturing parts for production expensive?

Manufacturing parts for production requires investment in equipment and materials. Costs can be reduced by optimising your design with Protolabs Network’s DFM analysis to lower tooling and cycle time. For many methods, including injection molding, unit cost decreases as order volume increases.

How can you cut costs of manufacturing parts for production?

You can reduce the cost of manufacturing production parts by optimizing manufacturing processes, reducing waste, streamlining supply chain and logistics, and adopting more efficient technologies.