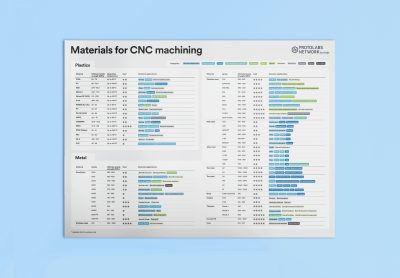

There are so many metal and plastic materials available for CNC machining, which makes it tricky to know which to choose for your application. Materials partly dictate the final cost and quality of your parts, so you want to be as informed as possible.

And while it's handy to have access to detailed comparisons of all the major materials available on Protolabs Network, it's optimal to have a single resource for making quick, smart comparisons.

Download and print our CNC materials comparison chart

This comprehensive poster contains all the information you need to know about CNC machining materials, including:

-

Prices of all CNC materials compared

-

Material strength

-

Operating temperature

-

Ultimate tensile strength (MPa)

-

Common applications across major industries

Download the materials for CNC poster to better determine which materials fit your application.

Know which materials you're using for your CNC parts?