Introduction

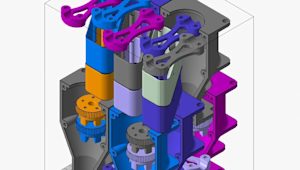

Interlocking joints are a practical method for engineers to connect components that will be assembled and disassembled repeatedly. They enable:

-

Fast assembly and disassembly

-

Reduced part count in an assembly

-

Joining multiple parts while avoiding process limits such as overhangs, bridges or support removal that can reduce print quality

-

Printing assemblies in multiple colors and materials

This article explains common applications of interlocking joints in 3D printing and recommends the 3D printing processes best suited to producing them.

3D printing technologies and interlocking joints

The table below summarizes common 3D printing technologies and their suitability for producing interlocking joints.

| Process | Description |

|---|---|

| FDM | Low-cost, effective method for producing interlocking joints, but accuracy is lower than other 3D printing processes. ABS is preferred over PLA due to higher ductility. |

| SLA | High accuracy, but parts can be brittle unless a tough resin is used. |

| SLS | Well suited for interlocking parts, offering high print accuracy and good strength. |

| Material Jetting | High strength and elasticity, combined with high-resolution detail, make material jetting ideal for interlocking joint applications. |

| Binder Jetting | Not suitable for interlocking connections. |

Designing for interlocking joints

There are three forces to consider when designing interlocking joints:

-

Friction: The primary force that holds the joint together. A tighter fit increases friction and makes the joint harder to separate.

-

Tension: The axial force that acts to pull the joint apart.

-

Shear: The transverse force perpendicular to tension that drives the joint to slide or tear sideways.

Interlocking joints accuracy

When interlocking joints are manufactured in injection molding, a tolerance of 0.1mm is applied. For 3D printing, tolerances vary between technologies as summarized in the table below.

| Process | Interlocking parts tolerances |

|---|---|

| FDM | 0.5 mm |

| SLA | 0.2 mm |

| SLS | 0.2 mm |

| Material Jetting | 0.1 mm |

Rules of thumb

-

SLS and material jetting are best suited for interlocking joints due to high print accuracy and material strength.

-

FDM is suitable for low-cost prototyping of interlocking connections when accuracy and durability are not critical.

-

Adding a small radius to part edges assists joint assembly and reduces stress concentrations.

Get a quote

Ready to print interlocking joints? Upload your design for an instant quote and process recommendations through Protolabs Network.