It may feel like there’s a never-ending rollout of new products and flashy tech, but to the engineers designing these products, innovations in manufacturing can seem incremental and slow moving. Yes, there have been changes and we’ve seen upcoming trends including cobots (that’s right, cobots, not robots) speeding up factory output, machines communicating with each other to optimize capacity, AI helping manufacturers make data-driven decisions and new types of CNC machines providing faster and more flexible solutions.

But what is still missing? What breakthroughs do we need to drive manufacturing forward? Why is existing technology underutilized and what new technologies are almost within reach?

We asked industry leaders, ranging from mechanical engineers and product designers to material-composite experts and tech journalists, to learn more about what could be improved in manufacturing. Here’s who we interviewed:

Left to right

Alex Huckstepp: Head of business development at ARRIS, a next-gen manufacturing company focused on composite materials.

Filemon Schoffer: Co-founder of Protolabs Network, an online manufacturing platform that provides engineers with on-demand access to a global network of manufacturing services.

Hardy Shen: Mechanical engineer who has designed products for SurfaceInk, iPhone, Nike, Oculus and more.

Richard Hulskes: Co-founder of Wevolver, a knowledge-sharing website for the engineering community.

Row 2

Robin Dechant: Editor of the Future of Manufacturing newsletter and co-founder of Aveo, an e-learning platform offering courses in manufacturing.

Sarah Goehrke: Head of DEI and board director of nonprofit Women in 3D Printing and senior director of strategic communications and ecosystems of Nexa3D, a 3D printer manufacturer.

Spencer Wright: Founder and editor-in-chief of The Prepared, a small media company focused on engineering and manufacturing with a podcast and very popular weekly newsletter.

8 ways to improve the future of manufacturing

The experts we spoke with zeroed in on eight major industry changes that could drive manufacturing forward. Some changes, like hybrid manufacturing and increased repeatability and reliability of 3D printing, are already underway. Others, like standardized machining for composites, are still far off. Each idea has the potential to alter the course of the future of manufacturing.

1. Awareness of—and willingness to use—existing advanced technology

Businesses often forgo state-of-the-art technology, either because they are unaware of it or because it is easier to stick with legacy systems. As a result, entire industries are often snared into using a single antiquated tool, such as Enterprise Resource Planning software, for daily tasks. SAP manufacturing software is one of the most-used industry solutions but it is complex and requires significant staff training to implement. “Companies are often required to work with SAP, which makes it hard to improve the process,” says Protolabs Network co-founder Filemon Schoffer. “If you could break through that, the industry as a whole would innovate much faster.”

Even when superior alternatives are available, adoption is anything but assured. “There is a huge learning curve that slows adoption and capability,” says Sarah Goehrke, Senior Director of Strategic Communications and Ecosystems at Nexa3D. “Though it can be a big effort, if decision makers can manage to find the time, budget, and training to incorporate more advanced technology into their design practices, the result could be better products, produced more easily and/or at a lower cost.”

2. Inclusivity

Companies that restrict hiring to recent graduates from top engineering schools can miss out on other viewpoints and the creative energy of people with different backgrounds, not to mention a richer workplace environment, according to Sarah Goehrke. “If you want to create different results, you have to approach the problem differently,” says Goehrke, who also sits on the Board of Directors and heads DEI efforts at Women in 3D Printing. “You can’t get better results doing the same thing in a slightly different way. For an industry that so prioritizes thinking differently, many companies make the mistake of hiring people with the same background.”

Goehrke is a firm believer in the benefits workplace diversity can bring to a company, and even to our collective futures. “This industry should look more like the world in which it operates,” says Goehrke. “Different perspectives may lead to products that serve a broader community and function better within the world. If the product isn’t making a difference, what is the point?”

3. Environmental awareness

Everyone—from engineers to consumers to governments—needs to be able to understand a product’s true environmental impact. Today, the data simply isn’t available.

Take a car, for example. From a consumer’s perspective, an automobile’s fuel economy may represent its environmental impact. However, fuel economy is a rate, not a value. A better indication of a particular vehicle’s impact might be its lifetime total fuel consumption. Better still would be the car’s “embodied energy”, which is the total amount of energy it took to mine and refine and transport the raw materials, then transform them into a finished car.

Global supply chains make tracking embodied energy fiendishly complex. Even the manufacturers themselves likely don’t calculate the embodied energy in completed vehicles.

The Prepared founder Spencer Wright imagines a world where manufacturers in all industries have an idea of the true cradle-to-grave environmental impacts of the components and materials they use, and the products they produce. “By far the biggest missing element I see in manufacturing today is some kind of rational way to track the externalities of your process—the greenhouse emissions, embodied energy, and end of life options.” Mitigating these things, says Wright, will be a huge challenge over the next few decades: “I think we really, really need a platform similar to ERPs and MRPs, that helps us understand how our activities affect the world around us.”

4. Skills and knowledge

As manufacturing gets ever more specialized, it is getting trickier to keep a workforce current on the latest technology and practices. “The skills gap is largely driven by the adoption of technologies such as AI, robotics or IoT, the aging workforce in Western countries and the fierce competition for talent,” says Aveo co-founder Robin Dechant. “This makes it impossible for manufacturing companies to simply solve the problem by hiring new people.”

Dechant suggests companies invest more in upskilling and reskilling to move some of their employees into jobs that are in high demand. “Using mobile solutions on tables and smartphones help to solve this problem since the skills gap also affects frontline workers on the shopfloor who are not sitting in front of a computer all day,” says Dechant. “And new technologies such as AR and VR can replace expensive in-person meetings with experts and to mirror machine handling virtually.”

A lot of the information is out there, but remains inaccessible. Richard Hulskes, co-founder of Wevolver, notices a continuing trend of open-source philosophy spilling over into the corporate world, as young purpose-driven engineers share their knowledge—and even publish papers on their new discoveries and techniques.

“A big challenge for engineers is that information is scattered,” says Hulskes. “If you are an engineer who wants to stay up-to-date on the field of soft robotics, for example, it’s really hard to find a single source of truth. And a lot of companies are out there creating great content but they don’t know where to share it.”

5. Innovations in materials

While some materials lend themselves to 3D printing, others still need to be reimagined and modified before they are suitable for use. Hardy Shen, senior mechanical engineer at SurfaceInk, is looking forward to a time when rubber prototyping will be faster and easier. “There’s no good way to prototype molded rubbers without using a compression molded tool,” says Shen. “You may be able to get close, but the performance is nowhere near the same as a properly molded rubber.” Today, iterating mold designs during the prototype phase can be particularly time consuming.

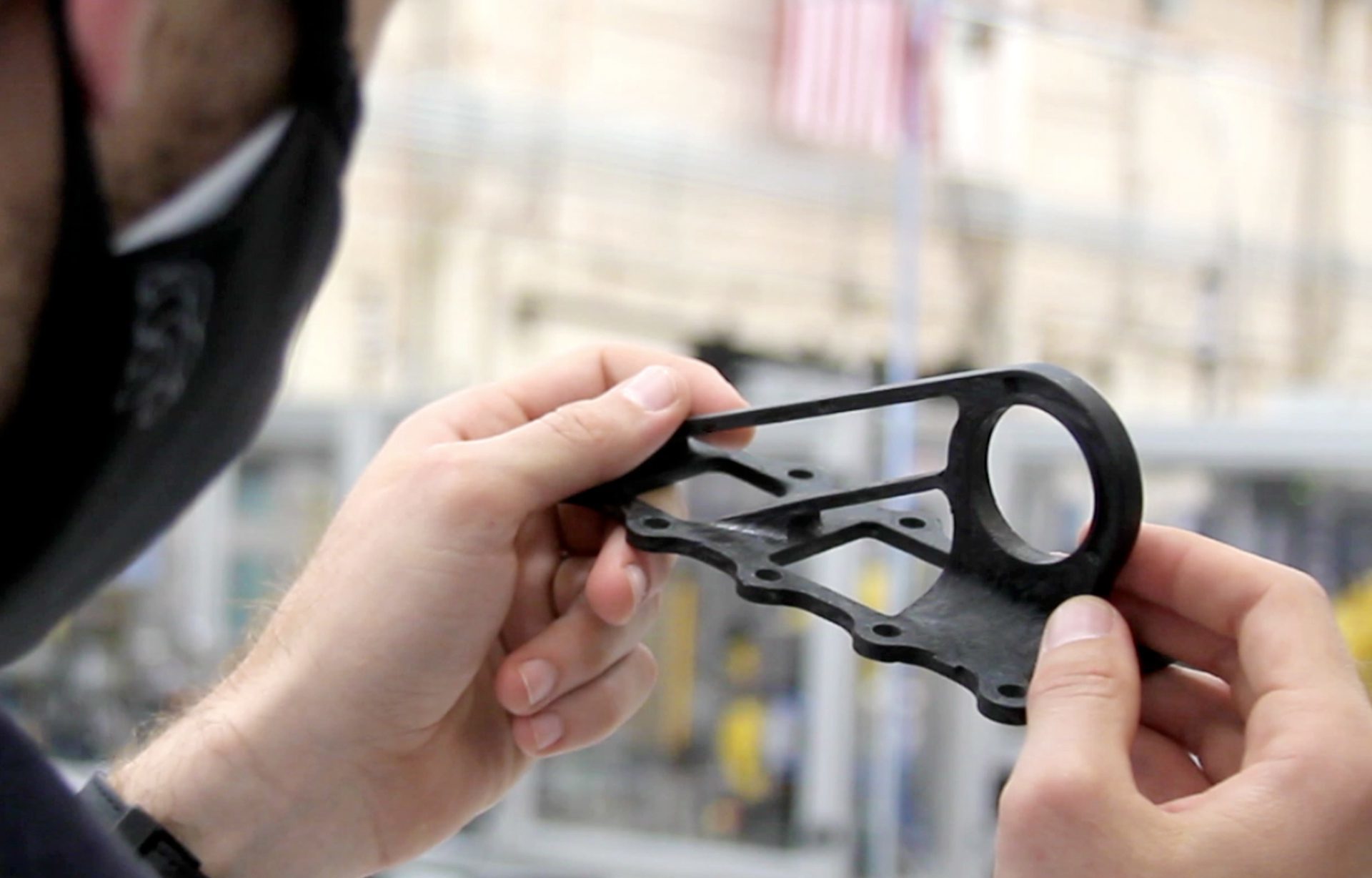

The situation with composites is unique. There are not many options for automating the lay-up and finishing of complex composite parts - none that scale well. Alex Huckstepp, head of business development at ARRIS, sees this as a big opportunity. “When it comes to parts made of carbon fibers—used in consumer products, sporting goods, airplanes and high-performance cars—the industry needs scalable processes and sustainable materials,” Huckstepp says. “There are many labor-intensive, wasteful processes today, and people are making millions of composite bikes, tennis rackets, and golf clubs by hand, for example, out of materials which are difficult to recycle.” Composites is a segment ripe for disruption.

While metals might seem like a natural fit for additive manufacturing, there are obstacles to the workflow. In traditional manufacturing, a material’s reflectivity is of little import when producing a part. When lasers are involved, however, watch out. Sarah Goehrke looks forward to materials engineered from the molecular level up, saying, “materials have been a big drawback. We need more materials to be recalibrated for additive. Metallurgists have been working on cool things, like reflective materials that work with these production technologies—without exploding.”

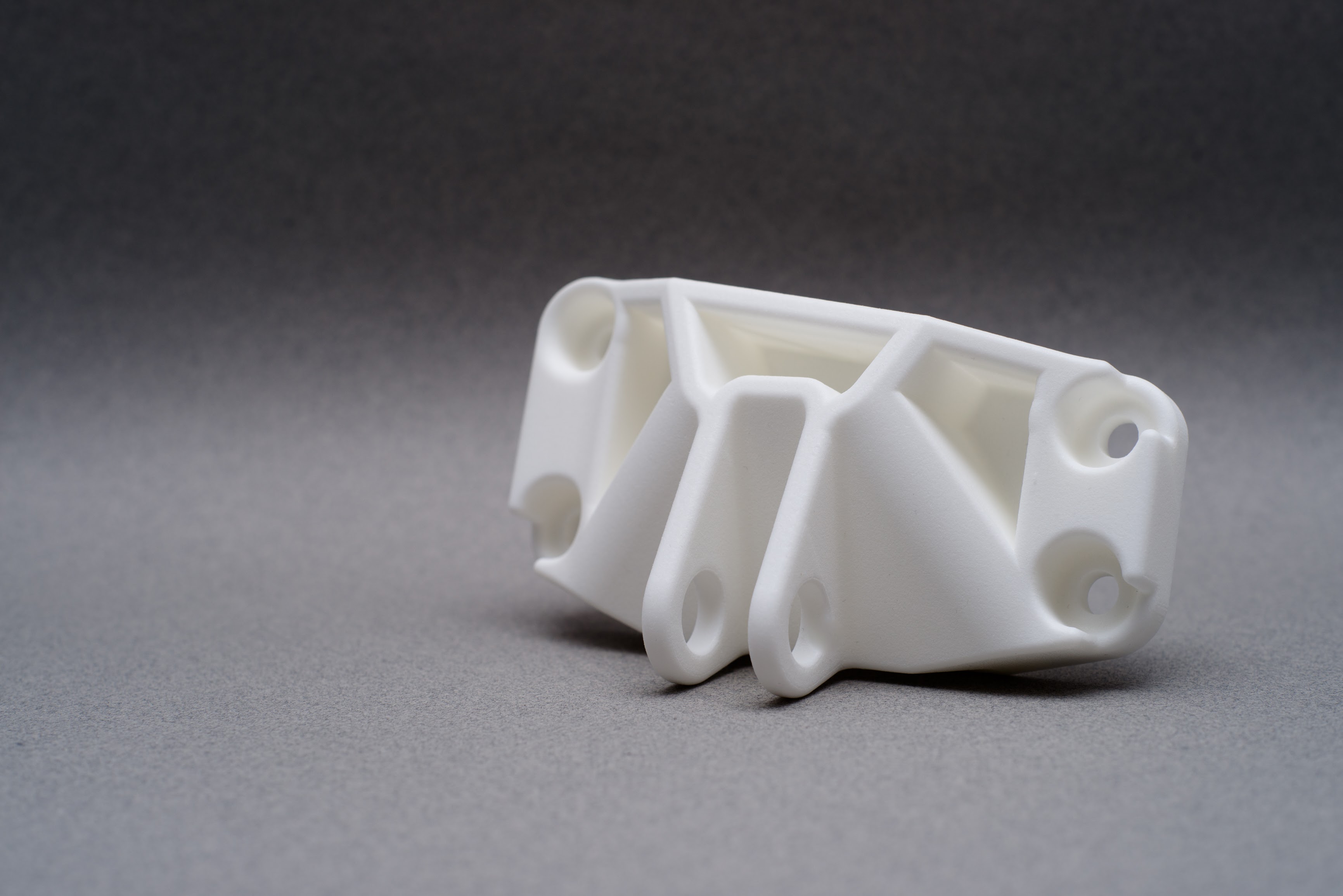

The advancement of additive manufacturing is the result of a massive effort across disparate groups. At the most basic level, however, it’s not possible to build a part unless the materials and processes to make it are available. As the materials improve, we will see more and more prototypes—and production parts—come from 3D printers.

6. Improved hybrid and smart manufacturing

By 2025, many seemingly futuristic technologies might become commonplace. But much of the advancement between now and 2025 will be born from incremental improvements in—and the combination of—existing technology.

Hardy Shen expects to see better quality and lower prices, particularly for metal SLS. Shen also says that “nylon SLS is at a point where it could possibly replace low-production injection molded parts.” A few years down the line, Shen foresees 3D printing reaching mass-production quality—but it will take improved reliability and repeatability to get there.

Alex Huckstepp believes a hybrid solution captures the best of both worlds. “Using additive and conventional manufacturing processes together provides design optimization, material efficiency, and scalability” says Huckstepp. “There is the performance advantage through complex 3D layup and then you can use conventional processes like molding to ensure part quality and throughput.”

Sarah Goehrke explains how many startups are using small-batch additive manufacturing to bring production dates forward. Says Goehrke, “the best use case for additive is alongside traditional manufacturing. It is best used in tandem. It might not make sense to print everything, but if you can 3D print your tooling, rapid prototyping can save months to years.”

As long as the pace of advancement in 3D printing continues, we expect that engineers around the world might be producing mass-produced 3D parts using 3D printed tooling comfortably ahead of our 2025 deadline.

7. Standardization in manufacturing

Standardization is the key to efficient manufacturing and there are many areas in the industry where standardization is lagging. The first is standardized pricing—anyone who has ever had a part produced will have seen the widely varying price quotes manufacturers offer for the same part.

Filemon Schoffer, co-founder of Protolabs Network, is working to crack the pricing quandary. “The Protolabs Network AI is aggregating data from manufacturers around the world,” says Schoffer, “and we’re headed towards becoming a real-time reflection for pricing in custom part manufacturing.” This would make it easier to standardize costs, and help usher in a new era of manufacturing as a service.

There is also room for improvement when it comes to translating CAD drawing into physical parts. “The actual machine doesn’t have instructions yet,” says Schoffer. “Engineers translate CAD to CAM but that’s currently more of an art than a standardized process. If one machinist does something clockwise and the other one does it counter clockwise, you’ll end up with slightly different parts. Because it’s not standardized, it is hard to have consistency across different manufacturers.”

There’s also a lack of effective live collaboration and version control tools. Programming has Git. Graphic design has Figma. What about CAD? Collaborative CAD tools still have yet to offer a perfect solution, and Schoffer sees room for improvement. “Right now, engineers use both CAD files and technical drawings. Often, we see engineers upload a CAD file and then a technical drawing for the details but the details can differ.” When there are multiple drawings for one part, it’s difficult to know which to use during manufacturing, and that slows down the whole process.

In the future, it would be beneficial to have one file—one single source of truth—for each part, as well as a standardized build process and a predetermined price.

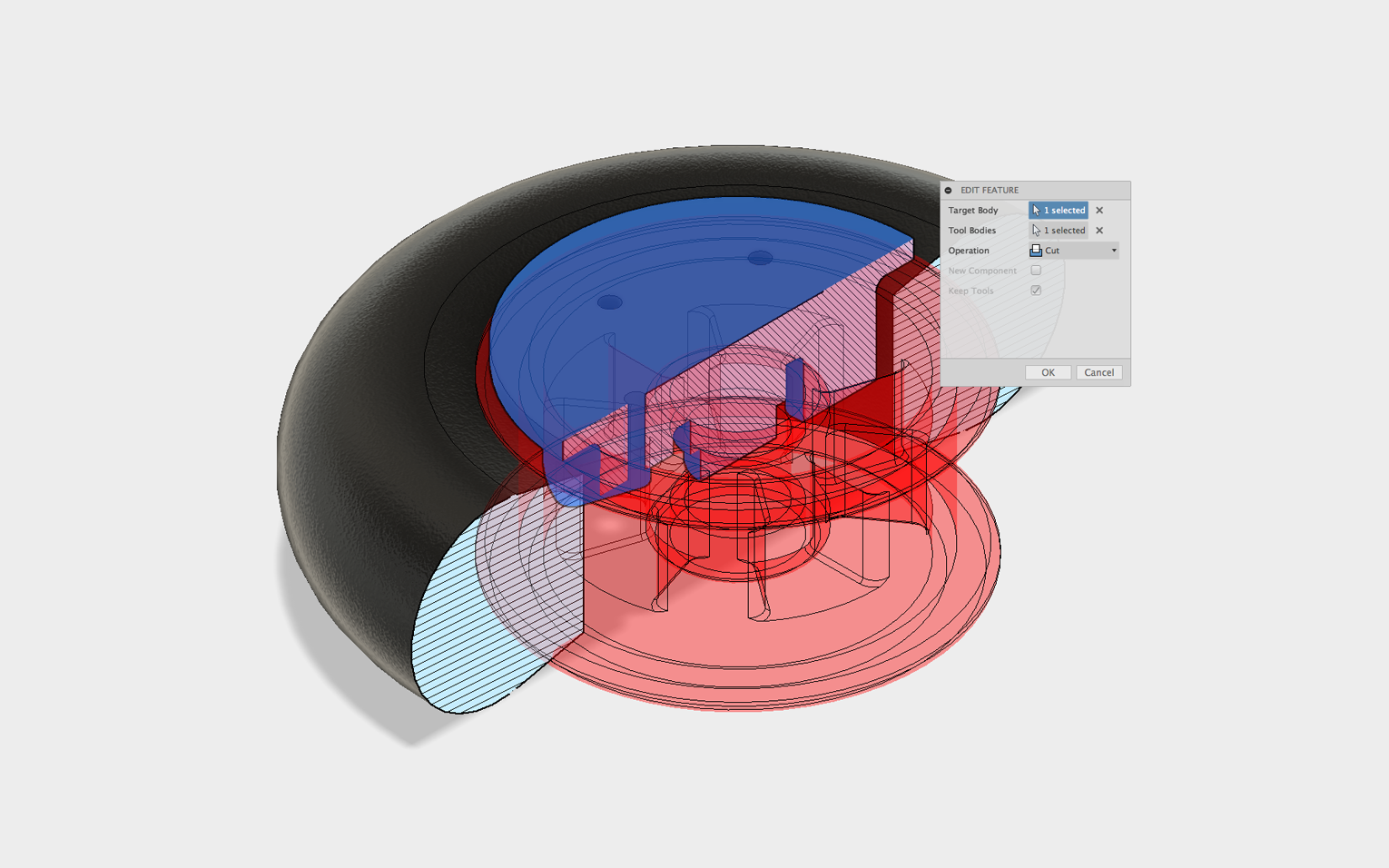

8.Improved design-for-manufacturing tools

In an ideal world, it would be possible to machine, print, or stamp whatever can be dreamt up on CAD software. While DFM tools are able to predict which shapes can be machined, the actual manufacturing process is more complex, especially with stamping. As a result, the prototype stage is longer for parts using materials and processes which may have characteristics DFM does not yet account for.

Hardy Shen has some improvements in mind. “We need the ability to simulate the complex forms to make sure they would stamp correctly in a tool,” Shen says. “Currently, the only way is to rely on personal experience, then have the contract manufacturer push boundaries when necessary.”

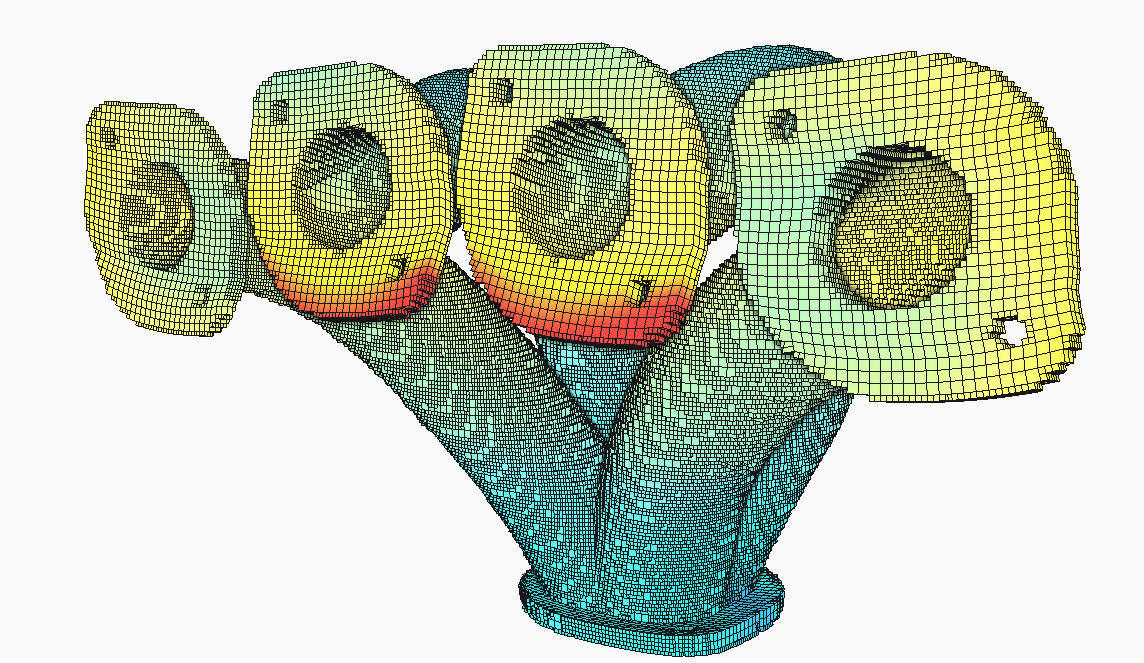

Although manual DFM is still the industry status quo, Alex Huckstepp is seeing specialized software tools emerge for optimizing designs for specific processes and materials. “ARRIS has built software specific to our Additive Molding process and continuous aligned-fiber composites to optimize product performance and manufacturing workflow in parallel. These tools are used on customer programs to inform part design (topology optimization) and material use, and then to validate through simulation before manufacturing. This appears to be where the industry is headed. Other companies like Desktop Metal and Carbon have also developed their own specialized topology optimization and DFM software recently.”

The Protolabs Network platform also incorporates a DFM tool that provides feedback on how to optimize orders. It automatically flags design elements that cannot be manufactured and adjusts issues that could increase the time or cost associated with your order, including hard-to-remove volume, hole depth, internal corners and thin walls.

Hardy Shen’s full wish list includes the ability to detect more potential manufacturing issues before production—these include heat distribution and accurate warping risk analysis. As DFM tools become more advanced, it will be possible to analyze a broader range of production techniques and save time by reducing the number of prototypes needed to zero in on a final product.

Beyond manufacturing trends

The technological advancements listed above are probably closer than we think, but the behavioral changes—like diversity in the workplace and awareness of new technology—might take longer. The human element in manufacturing should not be dismissed; as we approach the second half of this decade, we need to look not just to the latest printers and materials, but inward, to see what connections we can make and what sort of workplace culture can foster creativity and artistry. That’s how the most inspiring and exciting designs have been brought into this world, even before any of today’s modern tools were conceived.

Check out our trends page to download our industry reports.