As stated in the latest 3D Printing Trends report, HP’s Multi Jet Fusion (MJF) was one of the fastest growing 3D printing processes last year. At Protolabs Network, we make high-quality manufacturing easily accessible to engineers around the globe. Part of this mission is to put the latest industry developments in the hands of engineers. This is why we’re now making MJF available as a standard technology on our online manufacturing platform.

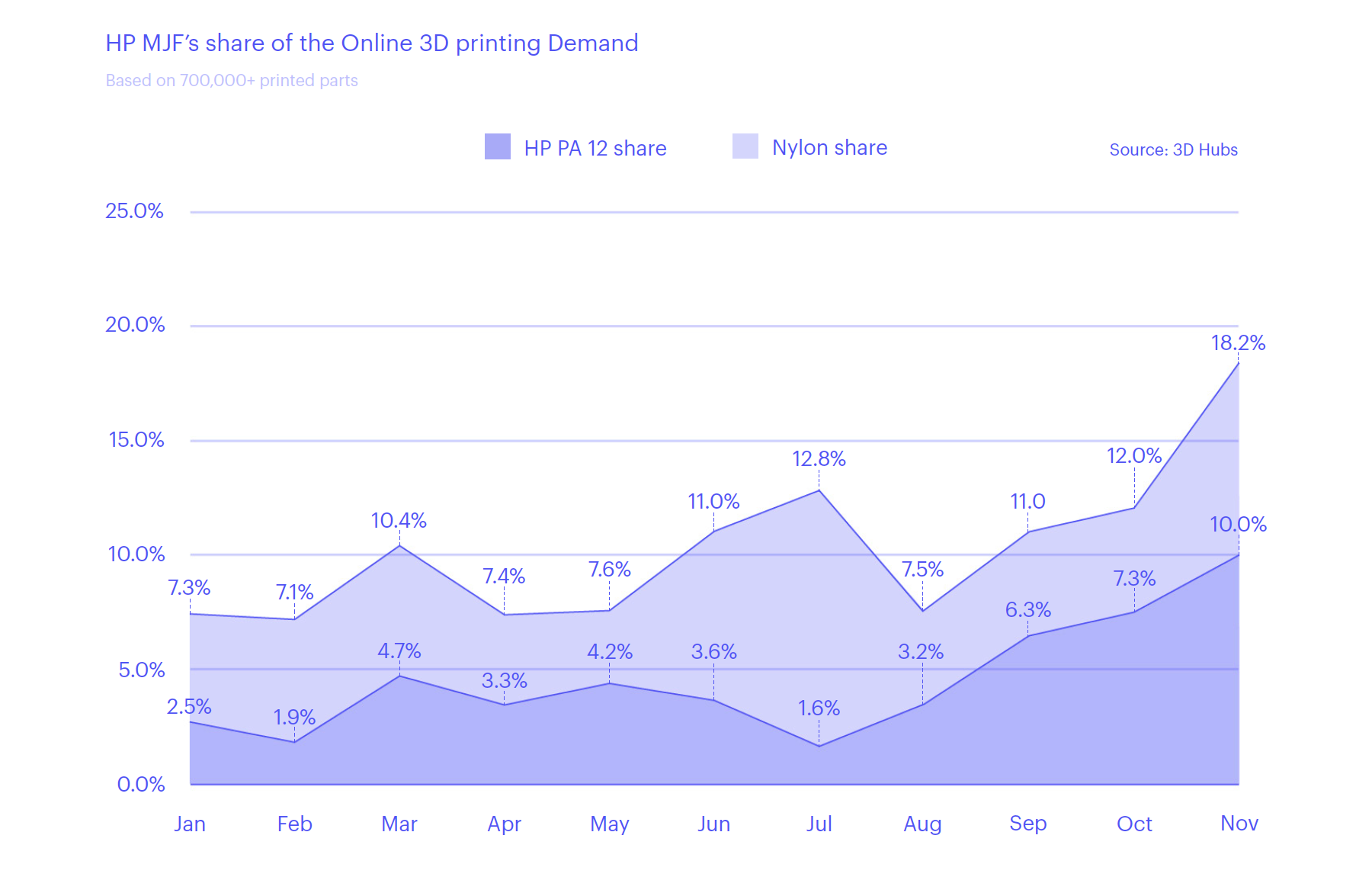

When looking at the industry data of 3D printed parts on a month-by-month basis, we see that the demand for 3D printing in nylon increased drastically from September of last year. This trend was primarily driven by HP’s MJF technology. Only during the month of November 2018, 10% of all 3D printed parts produced through the Protolabs Network platform were printed with HP’s MJF.

Why the demand for MJF will keep growing

Both HP’s Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS) are two industrial 3D printing technologies that belong to the powder bed fusion family. Parts are built by thermally fusing polymer powder particles layer-by-layer and the material used in both technologies are thermoplastic polymers.

When comparing MJF to other similar processes like SLS, then, SLS printers offer more material options such as carbon filled PA, aluminium filled PA (alumide) and flexible TPU.

However, MJF has advantages when it comes to dimensional accuracy and material properties, making it possible to print high tolerance parts that are superior in both strength and flexibility, compared to SLS. This is why we expect the demand to grow even bigger during 2019.

You can read a more in-depth comparison between SLS and MJF in this Knowledge Base article.

Protolabs Network doubles down on MJF

At Protolabs Network, we have built an online platform to make quality manufacturing easy and accessible to engineers worldwide. Part of this mission is to put the latest industry developments in the hands of engineers.

This is why we’re now making MJF available on our online platform**. To satisfy the global demand, we now have over 20 MJF suppliers in our network of manufacturing partners.

HP already announced that MJF will be capable of full-color and even metal 3D printing in the future which we're very excited about. At Protolabs Network, we’re keeping a close eye on these developments as they unfold so we can be among the first to offer these new additive processes worldwide.

** The new checkout is now available in the US, South and Central America, as well as Australia. Next on the road map is the release in Europe.

How to instantly source parts with MJF

- Upload your designs to the Protolabs Network checkout.

- Select 3D printing as your manufacturing technology.

- Select Nylon as your material and Nylon 12 as your type of Nylon

- Finally, select MJF as the process.

This will give you an instant price for your parts. When you’re ready, fill in your shipment details and send your parts to production. Your order will be in production within minutes.

Get an instant quote for printing your parts with MJF here.