Brian

2

Hey @Trevor_1 - good news we’re working on pretty much all of these. Let me break is down and make sure we’re on the same page for these features:

1. You mean canceling an order after it’s been paid or before it’s paid, the latter would be much easier as we don’t get into issues with refunds.

2. We’ve got this feature for the UPS partnership, which we are testing on our #Fairphone project. We’ve ran into a few things we need to fix there and then it will become available across Europe, and potentially the US.

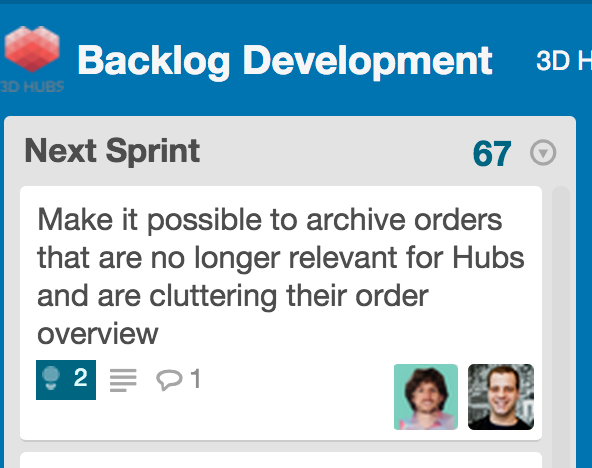

3. We actually just discussed this and it’s on the current sprint planning, so it should become available in the next 2 weeks. Attached is a screenshot form our Trello board so you know I’m not making this up

4. This too makes a lot of sense, we currently have the 20% infill and the 100% infill for almost all files so we should be able to work out something that allows you to scale between the two. Of course it would be nice to use more advanced slicers or intill settings and patterns.

5. Makes sense, I haven’t heard this one before, but if other Hubs are interested we could plan this feature too.

Thanks for sharing Trevor, if anyone else has feature requests feel free to post them as comments or share them on our UserVoice page.

Brian

1 Like

Filemon

3

This is useful. Thanks! We are actually working on a few of them. @Brian would you be able to shed more light on the specific points?

Cheers!

Filemon

4

Ah your reply just came in at the same time

HI Brian,

Do you want me to add these to the uservoice page?

Brian

6

Hey @Trevor_1, that would be great - however only #4 and #5, as the other ones are already close to being finished

AK_Eric

9

I’ve ran into this several times now: The ability for a user to modify an order before it’s “accepted”. Meaning, they can add\remove files. Currently the only option appears to be that they need to cancel the order and create a new one.

Also, there *really* needs to be a way to help figure out the cost of support material needed. What would be great would be if your server software could determine if supoorts were needed at all, and flag the print as “needs supports” or not. Then a ‘support cost’ could be factored into the print as possibly some percentage of the total. Just a thought

1 Like

@Robin3D @Brian what do you think?

Brian

11

Hey @AK_Eric I believe we support both these features up to some extent. We released edit and upload functionality to the order page last week (you should receive an email about this tomorrow). Secondly adding a charge for support material is possible from the order page. The only thing we don’t have atm is the technology to predict if a file needs support or not, this is however very much dependant on factors like:

- customers wishes/use case

- material + printer used for printing

- orientation of the part

- skill of the printer operator

So for our platform to realiably predict if support is needed, and only then to make the option of adding a charge for support possible seems risky/prone to errors. What we can do is make it more clear to the customer that extra charges might be added for support materials if needed. Would that work for you? For the time being we expect the Hubs to communicate this after looking at the file.

Best,

Brian

AK_Eric

12

I understand/agree with the issue you list: But something to ‘prep’ the user for additional charges if suppports are needed would be great, to help with expectations of cost increases.

When you tool calculates the “volume” of the item to be printed, what does that number actually mean / how is it generated? Is it (A) the physical volume of the solid, or is it (B) the volume of fillament that would be used to print it? And if B, what are the specs used to get that filament volume for a FDM/FFF printer (filament type, nozzle-size, number of shells, infill, etc)?

I always feel like that is a bit “black box”

thanks

Brian

13

We’ll work on the communication of the first part.

Regarding the volume we calculate 100% volume of the part for all non-FDM/FFF technologies, so for example a SLS, or full-color z-corp print always takes the 100% volume. For the FDM/FFF we slice with cura in the cloud and return the actual plastic required to print the object, using 20% infill and the standard settings regarding wall thickness etc. We also explain this in the FAQ, we plan to revisit this calculation in the near future, so you can expect some improvement here too.

AK_Eric

14

Thanks, I hadn’t seen that in the faq. Note the faq doesn’t list the number of shells.

That being said then, it’d be great if multiple slicing options could be provided to the user fromt the web interface: Have several presets available (like “standard”, “strong”, “hollow”, etc), plus an ‘advanced’ section so they could enter their own data (like Makerware) if they know what they’re doing.

Better yet, allow the hub operator the ability to make their own “pre-slicing” profiles the user can choose from via a drop-down: Giving us the ability to enter in the infill, number of shells used, and an option to check on ‘supports’ (which should be doable since you’re using Cura, right?) would provided a lot of power. Plus give the hub operator the option to change these after the order was submitted, so the operator could update the values based on what the user wants, and get a more accurate quote fore order acceptance.

Not that I couldn’t do all that on my side by discussing with the customer and doing my own pre-slicing, but I think the more you can expose this to the user before the submit an order, the “smoother” the whole process becomes. Once there is a back and forth dialog between customer and hub, things really slow down based on personal schedules, etc.

Food for thought

1 Like