I’m looking to have someone print some really small ultra high detail parts, on whatever machine is ideal. These parts are axial, as small as 0.9mm in some areas, and will be used as distinctive highly visible decoration on architectural models. They need to be smooth, ultra high detail, accepting permanent glue, and not so easily breakable by just a touch of an inquisitive finger. And I’d really like them to be a golden yellow if possible, otherwise the material would need to be paintable. Any suggestions what material to use? What machine to use?

2 Likes

What is the total size of the item? I have a machine and material that will work. The build envelope is small but the resolution is 30 microns.

There will be three different sizes:

8.2mm diameter

4.6mm diameter

2.7mm diameter

The height is about the same as the diameter.

One SET of these is as follows:

(1) 8.2

(5) 4.6

(4) 2.7

So 10 pieces total is 1 SET. These are so small that only the 8.2 shows up with any volume (0.1cubic mm) when calculated on the 3DHubs.com website.

Our initial print run would be around 250 SETS, meaning 2,500 pieces total. We expect to print lots of these in the coming years to supply our model casting factory so it is a repeat print job that could keep the machine busy for awhile.

Detail is our most important criteria. The architectural master model for casting was printed at 17 micron layers and we need an equivalent detail result for these items. Durability (these bits don’t break just touching them) is a secondary consideration. So they can’t look grainy or show layer lines to the unaided eye. I think something 30 microns we would have to see a sample close up.

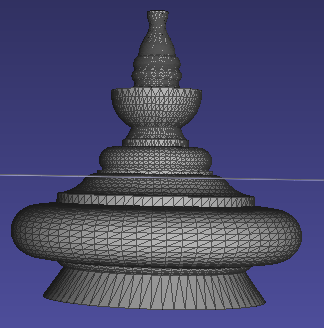

Here’s a screenshot of the piece.

BTW, the image shows the largest of the three. The other two are progressively less detailed and proportionately thicker at the narrowest points for strength.

When we are working at this level there are lots of factors at play, but I would be glad to print you a sample if you want. We are using a castable resin but making a master set then creating a mold might be a more economical way to make these. Again, would be glad to print you a sample.

EnvisonTEC Micro is the machine. I also have a machine that I built myself the has better resolution but less “dependability.” There are various photopolymer resins that we could use depending on the end goal. We are a custom jeweler and typically each item is a one off so we use a castable resin. For multiple production run items there are resins that are harder and better for creating a master mold off of and using HD castable resins within the mold.

Your mesh settings on your model are key as well to a great print but that is easy enough to check and make sure we arent getting any triangulation in the models from the mesh settings.

I think the models are easily enough redone if needed. Does it look too coarse? I’m not sure how to do that with my software, I just told it to revolve and it gave me this. Settings, I suppose. Using Delcam Designer.

I’ve seen HD mentioned elsewhere but I admit my ignorance. What is it referring to?

Casting is an option we’ve considered. Our casting shop usually does much larger items, I don’t think they’ve done anything near this small, not a jewelry shop. But they are clever people and if they can work out a production that won’t take a lot of time and money they’d go for that. Even metal casting could be the answer, I don’t know, but I suspect a resin in a ready to use color would be the best.

I’d like to get our shop guys’ further thoughts on it before bothering you with a sample, but please give your contact info in case they are interested.

You might want to check out ABS plastic injection molding. This piece would be easy enough to mill a metal mold and do direct plastic injection. Yeah… old school but at doing 2500 of them is a pretty good size run.