Hi all!

I wanted to print the Marvin keychain for approval of my hub but I got a hard time printing my marvin keychain.

I tried several things such as lowering temperature or speed or even print at higher temperatures.

I can’t get it right.

This is my Marvin:

Does anyone have a tip on howto make it right ?

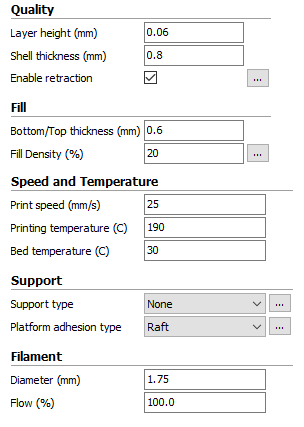

Edit - the Cura details:

Thanks in common,

- Dennis

2 Likes

Hi There!

I would maybe try using a thicker layer height, try 0.1 mm then 0.15 mm? The surfaces of your Marvin look amazing but I think those tiny overhangs just aren’t able to hold themselves up with such a small layer height. A thicker layer won’t droop as much around the edges and should hold itself up much better.

Cheers,

Martin

2 Likes

With that layer height your printer nozzle is spending more time on Marvin and making it so hot that melts the edges like that. Go with maximum fan speed and it should come out great. What type of nozzle you are printing with? Diameter? Your filament doesn’t look shiny like good quality PLAs (if that’s PLA) probably has too much additives.

3 Likes

Thanks for your reply!

I’m using Polymax PLA

Nozzle is standard provided with High settings from Cura.

1 Like

Hi Martin,

Thanks for your reply, I will check out as soon as I come home

Perry_1

6

Your layers are not cooling well enough before the next layer is laid down, which is affecting the helmet.

Same problem with the keychain holder part, except in reverse, you need cooler printing.

An active cooling fan will help. If you do not have one, point a fan at your print.

Also, print multiple marvins at once, or print the marvin along with a larger model. This will help your layers cool before the next layer is added.

Also, printing slower can help, and printing at a lower temperature can help.

2 Likes

Thanks for your reply!

Now running normal PLA.

settings:

Layer height 0.15

print speed 10mm/s

print temperature: 195c

bed temp 40c

fan 100%

minimal layer cool time 5 sec

What Settings are you using ?

Thanks in common

1 Like

Printing a new Marvin. Trying to use a external fan, higher fill rate… hope this will work Edit: so far so good! External fan really nailing it!

2 Likes

Thanks! He didn’t print the Keychain  so last night when I went to bed I made another one.

so last night when I went to bed I made another one.

2 Likes

Perry_1

11

You are getting there.

This is some additional advice, just to help out, dont know if they will help.

1. Again, print 3 at a time, or print while printing another model. This helps cooling on small parts, as each layer has more time to cool.

2. The fan is helping, so cooling is probably an issue. Perhaps crank your “minimal layer cool time 5 sec” up to 20 sec if you are still only going to print 1 at a time. (bettter to print several)

3. I notice you switched filament during your testing. I recommend against that.

4. Measure the width of your filament with calipers when you switch and put that into your slicer. Finally, you may be overextruding a little on the red one, which I do not see on the silver one. So, measuring is important.

The marvin helmet or eyebrows are a little bit rough. So I would say that you are overextruding slightly.

But all in all this is an acceptable print, I would think good enough to submit it to 3dhubs. Remember when you do that to pretend they are a real customer. Communicate the progress of the print, show pictures, etc., to get high reviews.