Hi there,

As PLA is sometimes considered as too hard as a filament for Fairphone cases, @Arquimaña started printing them with softPLA. He’s got some amazing result! Maybe you could share your tricks ?

@sandrako, @gabriela3d, @Luuk and the other admins, don’t hesitate sharing this thread to ‘your’ certified Hubs

6 Likes

Hello everybody, when printing in soft PLA we use low speeds around 20-30 and a temperature between 200-210.

Dispate being a low speed we don’t use low temperatures because the bridges will not print well.

Also, we use support to print the square gaps in the case.

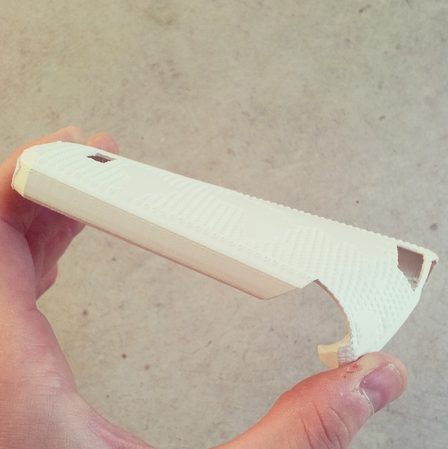

However, there are some things to improve. For example the overhang where the volumen keys are (see photo).

Also the edges are not as sharp as printed in hard PLA.

This model was printed 100% solid.

We are looking forward to see a fairphone case printed in some really flexible plastic as ninjaflex or filaflex.

Anyone tried it?

Cheers

Inaki

4 Likes

I tried it on my Ultimaker Original with black Ninjaflex recently. It was not very successful. The vibrations were just a bit too high when reaching the top. I would see more chances for success with a flex case lying flat on the print bed. And a Bowden extruder doesn’t help either…

Thanks a lot for your input, I’m sure other Hubs will learn from your experience

Just finished printing in Ultimaker Flex-PLA. Very happy with the print. It took some time to get it right but at 30mm/s 130% flow rate and 240 degrees and using a pushwire in the bowden it was successful.