Hi! I’ve been trying to print a few flat objects and haven’t succeeded once. Last time I tried printing Raspberry Pi case, and in about 10-15 minutes because of warping the plastic stops sticking and the print fails. I was using double sided tape with pretty good adhesion. Also tried blue painters tape with glue and it was even worse.

I’ve read about methods with hair spray, dissolving abs in acetone, but I don’t have a heated bed (using Printrbot Play).

What fix can you guys suggest? I just don’t know what to try next since the double sided tape I used was really sticky. Thanks!

KFix

2

Hi ! What temperature do you use for the first layer ? I would recommend to use the higher temp of your PLA specs to start then low it down to see what is your minimal adhesion temp (vary between brandi, or even between colors of a same brand). For my White PLA from ESUN, I get a good sticky first layer around 210° About the bed surface, blue tape is the Best IMO. If you still have adhesion problem you might want to tweak the Z-probe levelling… Keep it up ! And let us know

1 Like

Take a look at this picture, http://www.thingiverse.com/thing:994264

I’ve replaced the metallic bed with a 1/4 sheet of acrylic (Plexiglas) that was sanded on the top side with 80 grit sand paper. The only extra work you need to do is to get sticky aluminum paper (although you can use cigarette metallic paper with glue) for the proximity sensor, if your printer has the same system as the Makers Edition Simple model I own. If you don’t have a metal proximity sensor then it’s even easier.

1 Like

Use a raft, I had a similar problem but it was solved with the addition of a raft to the print.

I tried 210 and 200 and it didn’t help. Tried different heights for z axis and I was able to print little things.The blue tape failed completely when I tried it. Or do you mean double sided tape?

Thanks! Printrbot Play has a sensor, but what’s the aluminium paper for? The sensor won’t be able to see the transparent surface?

If so I’d have to cover the sanded surface with aluminium paper, but I don’t think it’s adhesive.

KFix

8

Nope, I meant Blue Tape (brand 3M) : http://www.abemus.fr/scotch%202090%20adhesif%20peinture%20bleu.jpg

When you say ‘failed’, you mean that your print doesn’t stick to it ? That’s odd, we’re talking about PLA right ?

If the blue tape doesn’t stick properly to the bed, and is pulled of by the wrapping print, that’s another story…

If your print is large, you might want to print it a little bit faster, to minimize the cooling.

I didn’t ask but, of course for flat prints with no heated bed, you should absolutly not use the fan for at least the 20 firsts layers (in 0.2mm, 40 for 0.1mm)

Yes, it sticks to the build plate. But the model I was printing didn’t stick at all. Double sided tape was more effective than the blue tape. What is so special about it’s surface that it is used for 3d printing?

No, because the sensor is electromagnetic, so it only sees metals like alum, copper, iron, etc.

If you look at the pictures, I’ve placed my aluminum papers only on the places where the sensors check in the beginning of the print and the area that it uses to Home x,y and z. The rest of the area is just the sanded acrylic. In some prints where the you’ll use the whole area, you will have a little going over the aluminum, but you could remove it before it start printing (I know it is not easy)

You can use a little of contact glue for the aluminum paper. Don’t use crazy glue or the like because it will be very hard to remove later…

I’ll take a better picture and a video of my printer when I’ll get to the shop later.

If you use the acrylic bed, you will need to put a little bit of lip balm on it to make it easy for you to remove the part when it’s done.

ehud42

15

Interesting - so you get no curl/lift from your prints with this approach?

How easy is it to remove the print?

I’ve been using a green masking tape, and find that while it holds the prints down reasonably well, it is almost impossible to remove the prints - often taking tape with them that is embedded into the print.

The curl depends on how much you can bend the base. The thicker the acrylic, less warping. Same with glass on the heated bed printers. I use 2.8 mm glass

The prints really stick to the surface so once in a while I use a little bit of lip balm or bee wax on the bed to make it easy (very) remove. But when you do make sure you sand it too. To compensate…

1 Like

ehud42

18

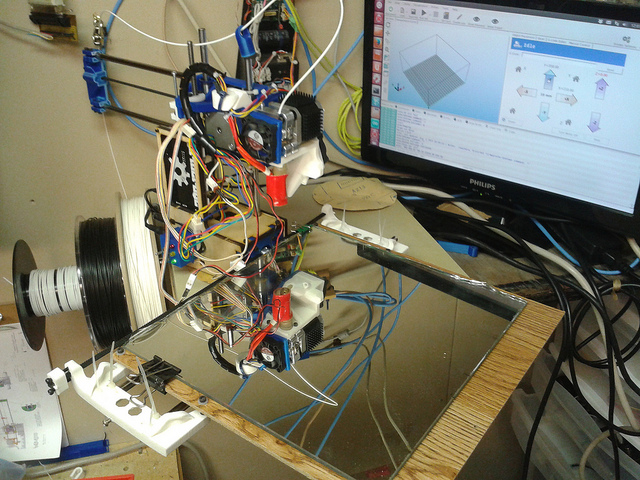

Nice! Will have to experiment with that. Currently I’m throwing around a (very heavy) glass mirror and it’s causing ringing/harmonics to show up in the print job. Am looking for lighter alternatives (I’m also printing a better design that doesn’t torque the bed so much).

COOL!

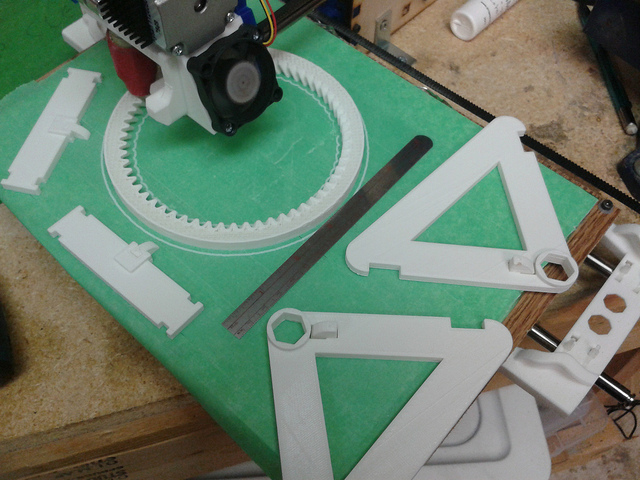

I want those custom parts you have! Did you design them? How big can you print?

You definitely need to try the acrylic sheet, a lot lighter on your printer. Will help you get even better prints…

ehud42

20

Ha - no I’m not nearly that smart. They’re designed by Jon Lawrence - he’s got designs loaded to Thingiverse (Thingiverse - Digital Designs for Physical Objects) and YouMagine (YouMagine – Designs by iamjonlawrence on YouMagine)

I currently can print 200x220x90 (lost some height in the conversion). I’m printing his designs from YouMagine and in between building a Printrbot #Frankenbot, hope to transfer the Simple guts to the new design from YouMagine (which will give the bed rods/bearings a wider stance and put the stepper between them - that should dramatically reduce the amount of twisting the bed does).