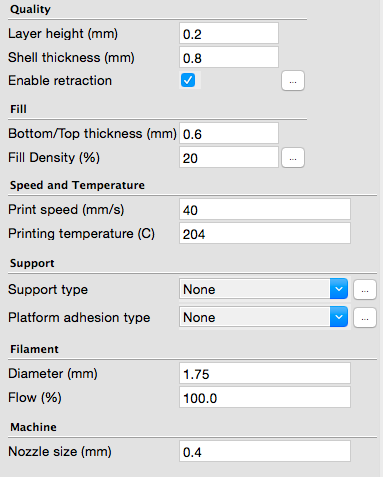

I printed one of my models on Printrbot Play with PLA and the print looks pretty messy. Here are some pictures, as well as my Cura settings.

(Dropbox - printrbot print - Simplify your life)

Could you please advice what I should change to get better results (maybe it’s not a software only problem, but something with the printer).

As far as I can tell - the main problems are:

-

Some filament is being extruded when the print head is moving from one point to another, it causes little “bumps” when next layers are printed and the top surface in the end becomes very uneven. I have “enable retraction” checked in Cura, maybe I should try lowering the temperature.

-

Even though it seems like more than enough filament is being extruded - there are a couple of lines missed on the first layer.

-

There’s a noticeable layer mismatch. Those upmost thin snaps should be right angled, but there are skewed, and the walls overall are not smooth (vertically) because of this.

-

Also I can see strange bubbles on one side, no idea what this is and what causes it.

I think I should try lowering the temperature and increasing retraction?

Maybe slow down the printer, but isn’t the speed low already? What are you thoughts?

Thanks, any help would be much appreciated

2 Likes

ianadan

2

Fine tuning any printer can take some playing.

I would for this part, increase the infill. The thin walls may suffer some of the calculation issues of trying to fit 20% in nothing…

The Z height looks a little high. Run M503 and see what the M212 value is for Z and try making it 0.05 more negative.

What are the retraction settings and who is the material manufacturer, both will make a difference to the stringing as PLA printing temps can vary from 180 to 220 in my experience.

What are you using on the print surface? Not that it would affect the print, I’m just curious…

if you are looking for better sidewall, try running the layer height at 0.1 or, if you want to stick at the 0.2ish size, use 0.1984, to compensate for the pitch on the thread.

Try these and see how you get on

Ian

I think your first z-height needs lowering at least. That first layer looks too high, just a tad. Try lowering your speed only to 20mm/s and see if the same part prints any different?

Steve

Videblu

4

The speed is slow overall, but the first layer is the most important layer. Some people go as low as 8mm/s to get a good first layer. If you don’t get a good first layer, you’ll get bad adhesion and a bad part. Try lowering the first layer speed.

Also, it seems like your Z-height is not calibrated properly. First, make sure your bed is level. Next, warm up your nozzle, unload the filament, and let the remaining filament ooze out of the nozzle. Once there is no more plastic oozing out of the nozzle, take a paper towel and clean off your nozzle. Make sure the metal on the bottom is not covered with plastic. Then, move to the center of the bed and Home Z only. Move up until the nozzle is not touching the bed. Then, move the Z axis down in 0.01mm increments until the nozzle is touching the bed. Do this while the nozzle is heated to working temperature! Once the nozzle is touching the bed, record the current Z-height from your software display. You want this number to be as close to zero as possible. If it’s greater than 0.1mm, that’s cause for concern.

I think reading this should help you: Print Quality Guide | Simplify3D Software

It does look like you have the temp too high. I never print PLA higher than 200c on my simple. It also looks like your extrusion is inconsistent. May be the pla itself causing this. Try swapping the filament out with a new roll.

Have you also gone through the videos on the printrbot site to calibrate your z-height?

1 Like

Huge thanks, everyone for the replies! I checked the auto-leveling probe according to the Printrbot calibration guide. It was a tiny bit too high as for me, which is strange, since the higher the sensor is - the lower the nozzle goes.

My Z setting is -0.6. I lowered the temperature to 195 and tried printing, for some reason huge blobs started pouring out and the nozzle was smashing into them. And it seemed like this time it was printing too low.

I suspected it’s over extrusion, tried calibrating the extruder by extruding 100mm of filament, but it was almost perfect. I changed the temperature to 205 and Z height to -0.4

Tried printing, the first layer seems to be better, but the layer mismatch in X direction is horrible! I suspect it’s a hardware issue, because I noticed the Z rod wobbling. Also the nozzle is wobbling, not sure if it should. Please see the videos and pictures on my dropbox:

Could this be the issue and is it possible to fix?

Maybe the belts are the problem, but they don’t seem to tight for me, I can bend them with my finger.

Do take a hex wrench and tighten the extruder block if the extruder is that wobbly. Have you tired swapping out your filament? Contaminated filament can blob up due to moisture contamination. Are you storing your filament with desiccants in a airtight bag or container?

No, I’m just storing it in my room. Unfortunately I don’t have another filament right now, but after printing a bit higher there were no blobs, but the layer misalignment is a huge concern. What do you think of the z rod wobbling?

No I don’t think the rod is the issue. I have a printrbot simple at my work with a rod that wobbles worst than what is displayed in your videos that you post but the prints the machine produces is excellent. Did you tighten the bolts on the extruder block so the extruder doesn’t move? Also check and make sure the fan is tightened down too.

It may be beneficial to try a different slicer software or install a older version of Cura prior to 15.4. I gave up on Cura a long time ago because I never could achieve decent prints and always had techinical issues that I thought were hardware when in fact it was due to the Cura Software.

The majority of those issues are caused by over-extrusion. You can reduce your flow percent. Or alternatively (what i have actually done with my printrbot simple) adjust the extrusion rate in the firmware settings.

Here is a very detailed guide:

http://joshondesign.com/p/books/simpleguide/text.html

Scroll down to the section “Calibrating the Extruder”, basically you have to mark a line on your filament, measure how much it is travelling and compare that to the distance you told it to go in software. You can then use a formula (on the guide) and/or trial and error to get the right value.

Once you do that I would check these out as well:

https://www.simplify3d.com/support/print-quality-troubleshooting/

http://reprap.org/wiki/Print\_Troubleshooting\_Pictorial\_Guide

NOTE: I have never really worried about how i store my filament, i just leave it out all the time and I can get very good quality prints even as low as 0.16mm layer height.

(I am assuming that the printrbot play has the same control board as the earlier printrbots)

Hope that helps!