Daren

1

You need a 3D Systems CubePro Duo, or a 3D Systems CubePro Trio to use this material effectively. I need @8 machines to print 8 parts of one model. Anyone out there using all three nozzles? Anyone out there using 2 nozzles? Are you having success?

1 Like

I have just bought a TRIO, started using INF but software is such a piece of crap that I have reversed on Simplify. Unfortunately there is no option yet for INF in it. I have printed a little part using INF, it is good but to remove it it will be a good idea to have more than just hot water, you need the ultrasonic device they sell.

Daren

3

Wow, small or big world, you are a long way from Nashville. Cool you have invested in the TRIO. I haven’t had problems with the cubepro software. Have you updated both the firmware and software? Latest firmware cubepro V1.12A, and latest software V1.72 ?

I have used all three nozzles on the same print and it was just crap. The software is useless, hardly anything good comes out if you can’t control settings like retraction or speed. I used to print abs with pla supports and rinse them in hot water; supports get softer but they always left ugly scars and color contamination. Since I purchased a flashforge with simplify3D never used my trio again, supports really work and you can take them off very easily.

Daren

5

Octopuslab,

Do you have any photos of your work with supports? Could you reproduce something like this? http://www.easttowerdesign.com/b/JPEG/etd197.jpg

I am a reseller in Texas. My demo unit is a Trio. I use all 3 print jets. One is INF.

I have not had any trouble with the software as long as the firmware version matches it.

My INF experience did require a little more than a hot water rinse or soak. Most of it came off and the bits that still remained were soft enough to pull off or grind off

Daren

7

Infinity supports have been effective in initial testing.

Not yet installed 1.72, there is said there is some kind of bug, told to me by the people that sell this printer in Italy. I will check tomorrow morning about firmware. At the moment I am stopped by an F12 error, regarding a problem with extruder. Anyway do you know if it is possible to use Simplify?

Hi Darren

I use the formlabs SLA resin printing which have supports that arent always easy to remove… Been thinking about buying a FDM printer with dissolvable supports

are these dis solvable supports?

thanks

Elliot

www.microworkshops.co.uk

Daren

10

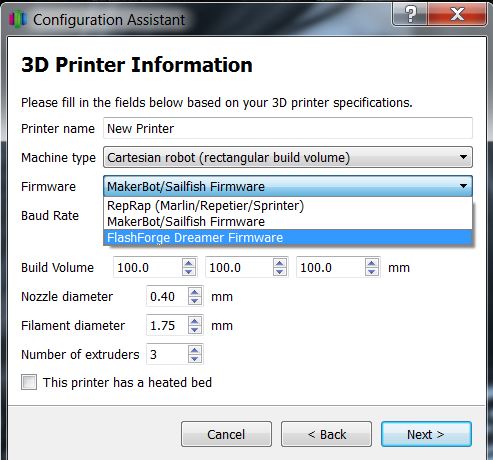

I am not sure about Simplify. I looked on the discussion boards and saw mention of Cube, but did not find any 3D systems machine support on the pulldown menus. I also see only three options on firmware that the software works with. It appears at first glance there is no support for 3D Systems.

Daren

11

Yes, the material is made by Cubify and is called Infinity Rinse Away with a three letter abbreviation of inf.

The material is water soluble. It just takes time, sometimes, like with this model a few days.

http://cubify.com/cartridges/infinity

soso

12

Hi Daren.

I use a Duo and two Trios and i made several prints with PLA, Nylon and infinity-rinse away material without any problem.

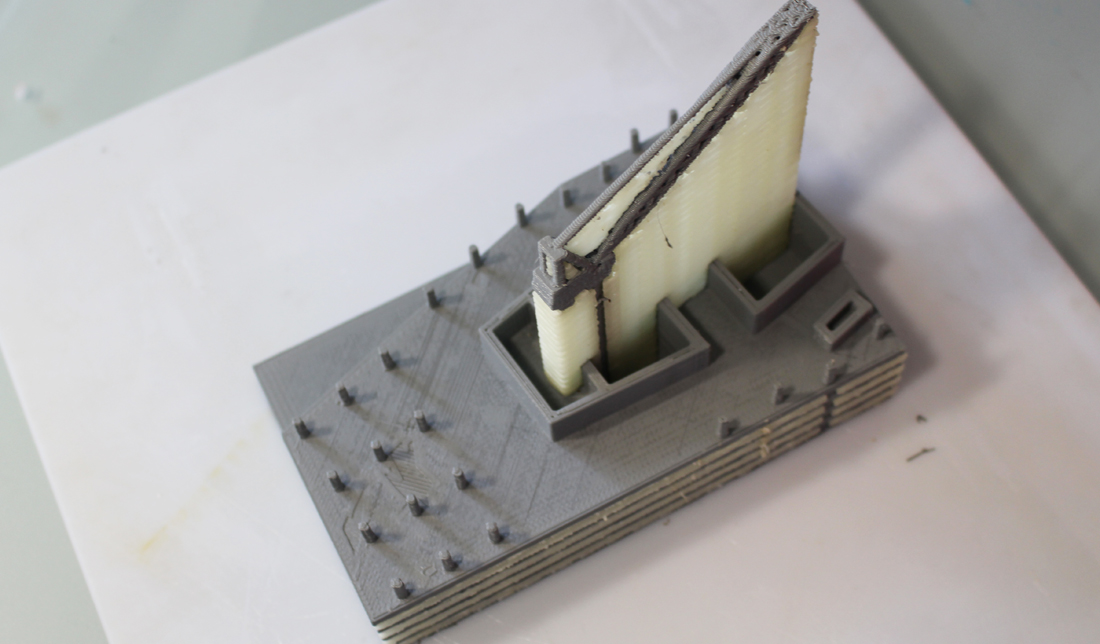

I attach pictures of my last PLA print.

Here is a picture of the downside of a cap, on the right are the supports. As you can see, they came out in one block and the flat surface is pretty clean. Unless it’s a really intricate shape, I don’t see the need for washable supports. Unfortunately, we can’t use simplify3d or any gcode generator on cubes. The printer, the chips, software… everything is meant to waste their overpriced filament and justify their expensive ultrasonic tank. The most I have been able to do is lower down PLA temperature (set by default at 210C which I find very high for small or detailed elements particularly on a enclosed chamber) and that helps a bit to improve the print quality. I’d print all the elements in your models separately so they all come out nice and clean. Printing it in straight position requires a lot supports for those flat overhangs and in the picture looks like there is very little space to reach out to them. Maybe you could try to rotate it to the side, like in your etd197 pic, so all those flat floors won’t require supports and only the pillars and small elements will be overhangs.

Daren

14

Most excellent print work. It may be I could utilize your machines. I will submit a file for estimate.

Daren

15

Interesting points. I tend to agree on cost issues, I am testing the INF material and getting good results. Current print is imaged below.

https://forum.simplify3d.com/viewtopic.php?f=8&t=3113

Firmware of my CubePro is 1.12A. I have tried to use Simplify and it works far more better: unfortunately not yet any FFF profile for using INF.

TONYDG

17

This is great.

I have a cube trio. Using Nylon and INF with the normal settings.

I havent been able to print anything with INF. My extruder keeps klogin and the one with nylon the material comes like with bubbles. Can you plesase help me.

Thank you

AD

Daren

18

One of the first INF cartridges I used, failed. It was determined that the INF was defective. Also, unrelated to the defective cartridge, if your extruder comes back with a filament error, it is possible the remaining previous material has jammed the extruder. I have not tried nylon yet. Have you used Simplify 3d with your machine yet? Have you ever removed an extruder and cleared a jam?

INF material are very sensitive to moisture , I tried to remove it using an oven but its impossible. I recommend to deinstall de cartridge from printer if it don’t will be used for several days and store in a closed bag with silica. I live in buenos aires mean 70 % of humidity… Nylon are also vey hygroscopic but in this case there are solution, you need to remove the moisture in a 50…60 C oven for at least 6 hours.

Regards, Patricio