Hi all,

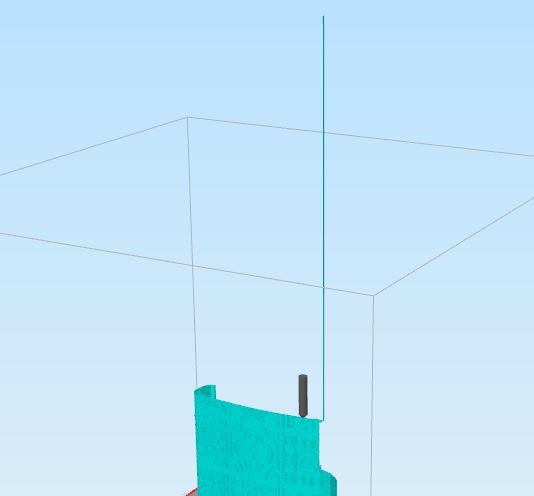

I have a returning issue with printing Fairphone cases. Near the end of the print, the overhang on the opening on the side is not printing well (see pic.) Anybody knows how to fix this?

6 Likes

Luuk

2

Hi Filemon,

I thought of a few things which might help:

• print more slowly (at that specific point)

• print at max. resolution (then the lines are overlapping more whilst moving towards the outside)

• fan at 100%

• coolest temperature for material (but make sure the layers adhese enough)

Good luck!

wayne

3

my first thought, based on the overhang you mention and the slight sagging in the bridging, would be to try lowering the extruder temperature.

It might be useful to know:

which printer are you using?

what material are you printing in?

at what temperature?

I did not get the problem… but I have good results with a Replicator 2 and those parameters (perhaps could help):

- Material: PLA

- Raft

- No Support

- Profile: Standard

- Infill: 20%

- Number of shells: 3

- Layer height: 0.15mm

- Temperature: 220°C (really depends of your filament)

- Speed while extruding: 30mm/s

- Speed while traveling: 90mm/s

The process is quite slow (about 5 hours for a case) but the result is really great.

Thanks! Although I print on an Ultimaker 2 at the moment (do have Makerbot as well) it’s good to see what settings work for you. Willl try some new stuff. Cheers!

zaxis

8

Good Tip is print slower at this section. 20mm/s I use and temperature as low as possible. I use 200 degrees.

And use good filament, I’ve a china no name filament and thats a mess. Printing with 205 degress causes filament blocking cause it doesn’t melt correct and with 208 degrees it flows away.

I current use for these cases colorfabb.

zaxis

9

Good Tip is print slower at this section. 20mm/s I use and temperature as low as possible. I use 200 degrees.

And use good filament, I’ve a china no name filament and thats a mess. Printing with 205 degress causes filament blocking cause it doesn’t melt correct and with 208 degrees it flows away.

I current use for these cases colorfabb.

Here are some photos of the last case using those parameters.

Yep @ColorFabb works great, I agree

@zaxis Yes, that’s spot on. It’s always about finding the right compromise between Speed/Quality.

For this case I found I get good result at 200 degrees at 30mm/s whilst also turning the case so the critical overhang is well covered by the fan. Due to the higher viscosity of the plastic it’s sometimes worth increasing flow by 5-10%.

It’s also worth remembering that if the overhang is close to the bed, the bed temp should be kept to a minmum.

You may also find this plug-in for Cura usefull which allows you to change the speed at a specified Z height http://wiki.ultimaker.com/CuraPlugin:\_TweaktAtZ

Wow, nice! Please stick around for any other questions I might have

Filemon,

which design is is - I found that one or two of them have some errors in the stl that cause a wierd z shift just on that point and it means that the printer pops up for a second, oozes and then pops down again and then resumes as normal. I contacted Joris but he cound not see a problem - so I fixed one in meshmixer (the lucky cats case - there was a tear there, and the Day 3 case I edited the Gcode where there was a jump in the z and removed it.)

So it depends on whcih design it is as everything else looks good.

James

Hi James,

This about the day 4 case, the one with the mozaic kind a look.

Although I stated “succes” yesterday I’ve ran into the same troubles over night. Will now try an even slower print. See what that does.

Cheers!

Filemon,

I don’t think that will fix it - here is a slice in Simplify3D and it shows the problem I was describing (but really bad) see there the line come off the phone case vertically - that is a HUGE z shift - so it gets to that point, then lifts off the phone, then comes back down and carrys on but you get a large strig of plastic.

If you are happy editing gcode (a good time to start  then slice the case - save to gcode and open the code in notepad and you will suddenly see a Z that is way out at about line 151563

then slice the case - save to gcode and open the code in notepad and you will suddenly see a Z that is way out at about line 151563

Edit the z so that there is no change and save the gcode back as gcode and you are good to go

If you are doing it on a UM1 then I can do that for you here and email it.

OR - you can download meshmixer free and ‘heal’ the wound.

OR go back to joris and ask him to have a look.

I don’t think slower will fix it - if you want to test t then just start from just below that point (tell your UM to push it into the print bed)

Good that you are experiencing the pain of a hub

James

Thanks James, very clear. Now… which option to choose…

Will update Asap

Cheers!

Filemon

key23d

20

Hi Filemon,

I have printed a couple of cases already but not the day 4 one! I will let you know when I do.

I looked at it though and I must agree with all other opinions on this talk: temperature and/or speed.

Maybe your fan is not on or directed properly? (but then you would have more problems  ! )

! )

Attached an insight look because there are multiple problems with this case and I would like very much for you to go to Joris and ask him to fix this because it is not doing anybody any good!

(not only this case but the other ones also)

Hope this helps!

Kind regards, Guy

FairPhone case day 4.pdf (292 KB)