Hi,

I’m printing with the Colorfabb XT-CF20 filament with the new E3D nozzle. All going good, but it looks like the XT-CF20 filament extrudes allot more than PLA on the same flow settings.

I calibrated the extruder so that 100mm filament is really 100mm, with PLA that was perfect, but now with the Colorfabb XT-CF20 it looks like I’m overextruding allot.

After a print the nozzle is full off filament that sticks to it, a large blob of filament. Also, when I’m printing on 80% infill it fills the print totally, so all solid layers.

Is it normal that the CF20 filament extrudes so much more? What should I do best?

2 Likes

MB3D

2

Check the diameter of the filament and play around with retraction settings.

Diameter is same af the others, I indeed should play around with the retraction settings, but that doesn’t fix my over extruding problem?

MB3D

4

The different retraction settings can solve the string printing between start and end of retraction moves.

But that is not really the problem, it can be caused by retraction, but I mean that while printing, there is a buildup of filament that sticks to the nozzle, and it gets more and more the longer the print is.

It looks like when the printer change layers he leaves a little blob, and when the nozzle passes that blob on the next layer, it sticks to the nozzle and keeps there for the rest of the print. When a printjob is finished the nozzle is fully covered in filament.

I tried different retraction lengths and speeds, but no advance, maybe printing temperature?

What speed and temperature are you going at? I find that at 260°C, the melt is much too liquid to produce good results. 240°C causes more empty spots on horizontal surfaces, 250°C seems like a good sweet spot so far.

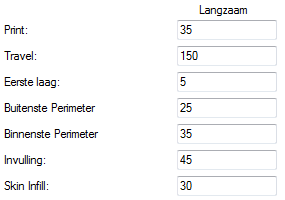

The globbed up nozzle indicates to me, that you are going way too fast. I usually don’t exceed 35mm/s and only get very little deposition on the nozzle tip, which from time to time even wipes off on infill. Going too fast could also explain your phantom overextrusion. Just from a manual test you can see, that if you push in filament slowly, it comes out at roughly nozzle diameter. But going hard and fast will leave you with a thicker string.

Conclusion, slow and cool get’s you places! ;D

Thanks, printing slowest from my settings. What do you mean with 35mm/s infill, perimeter, travel,…?

Well, think about it. This is an extrusion speed dependent problem, so…? All speeds where material is being extruded need to be slowed down. Travel moves can still be as fast as the printer can take. Personally I am not a big believer in changing infill/perimeter/inner/outer speeds individually, but if it floats your boat, keep any of them below 35mm/s. Let me know if this fixed your problems.

All that is above 35 is only infill, but still I’m having this extreme extrusion, even on the perimeters…

Have you tried drying the filament for a few hours at ~60°C in an oven? Carbon fibre is prone to absorb moisture at room temperature, at least in its woven form.

I would like to bring this up again, because it is still not solved. When printing, the filament always builds up around the nozzle. I only have this with XT-CF20, and later in the print it drops it, ruining the print. I tried playing with retraction, speed, extrusion, temperature,… None of them helped. I’m using the special nozzle from E3D, specially made for this filament. Anybody that has tips?