BuildTak / Fleks3d / Proto-Pasta Product Review

BuildTak

Price: $4.00 to $21.00 depending on size and quality

Specs:

4.5″ x 4.5″ (114*114), 6.5″ x 6.5″ (165*165), 6.5″ Diameter (165Dia), 5.83″ x 7.95″ (202*148), 8″ x 8″ (203*203), 8″ Diameter (203DIA), 6.25″ x 9.25″ (159*235), 6.5″ x 10″ (165*254), 6.5″ x 11.5″ (165*292), 8″ x 10″ (203*254), 9″ x 10″ (228*254), 10″ x 10″ (254*254), 12″ x 12″ (304*304), 12″ Diameter (304Dia), 16″ x 16″ (406*406)

http://www.buildtak.com/

Fleks3d

Price: $20.00 to $73.00 depending on size and Simple or System Kit

Specs:

M3D, 4.5″ x 4.5″, 6″ x 6.″, 8″ x 8″, Makerbot Rep 2, 6″ x 9″, 10″ x 10″, 12″ x 12″, 8″ Diameter, 15″ x 15″, Dreammaker Overload

http://www.fleks3d.com/

Removal of Print link here: Fleks3d New Build Plate - YouTube

Proto-Pasta

Price: $33.00

Specs: *Cut upon order*

https://www.proto-pasta.com/

Removal of Print link here: Proto-Pasta's New Build Plate - YouTube

I would like to start by saying even though these 3 products help your print adhere to the bed of your printer I would have to put BuildTak in its own category based off the thickness and use of the product. A characteristic that all 3 products have is that you can use the same build plate for ABS, PLA, and composites without a problem.

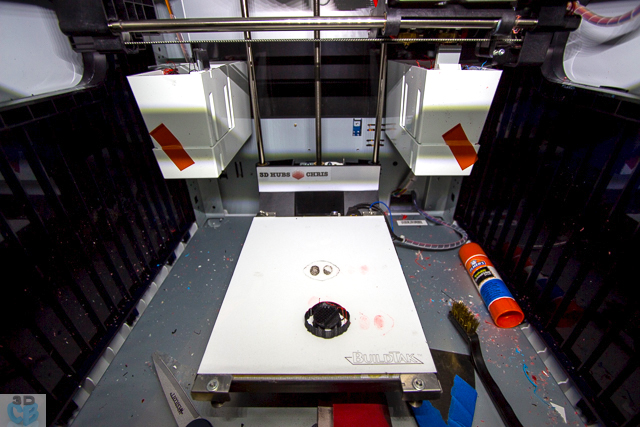

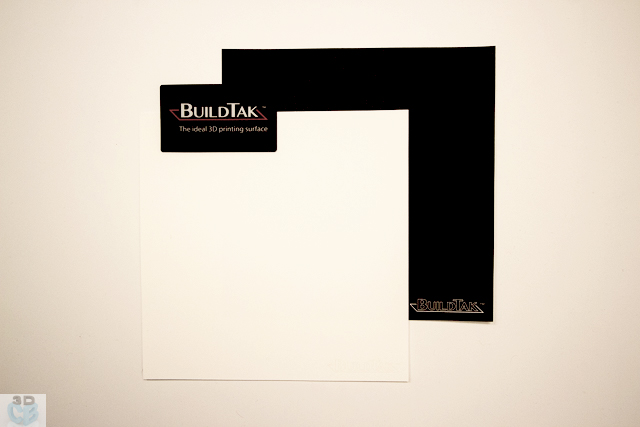

BuildTak is a thin sheet with adhesive on one side to allow it to stick to your bed. BuildTak is also very easily be cut with scissors or an Exacto Knife. BuildTak works very well but can cause an issue if you calibrate you printer to close to the bed. If you do you will have a VERY hard time getting your print off the bed. Unlike the other products BuildTak does not last as long and cannot be removed and reapplied like Proto-Pasta and Fleks3d’s products meaning the money you save on BuildTak you spend resupplying your stock which is also why they sell in packets. No it’s not like Stratasys build plates that are one and done but if you do daily prints you will have to replace every couple weeks. A great feature to this system is it allows you to use heat which is important for ABS prints.

Proto-Pasta’s newly released build plate has many similarities to Fleks3d, both are a thin plastic-like sheets that that are directly applied to your build plate which can be fastened on with binder clips and allow the user to pop the print off with a single bend of the plate but they start to differ from there. Proto-Pasta’s build plate allows you to print with heat applied on your bed, for example if you are using a stock XYZPrinting Da Vinci you cannot turn the heated bed off, Proto-Pasta’s plate will not warp due to the heat like Fleks3d will. Another difference I have noticed is that with Proto-Pasta’s plate they ask that you still use your favorite adhesion method, whether tape, glue stick, or Kapton tape where Fleks3d doesn’t require any extra adhesion. As seen on Proto-Pasta’s site they actually applied BuildTak to their build plate and were able to pop the print off their bed with little effort. Which does make a good combination!

Fleks3d is a new product that just successfully finished and filled all orders form their Kickstarter Campaign. Fleks3d is a great product that comes in many different pre-cut sizes to fit most common FDM printers on the market. Fleks3d offers two prices on their website for a product with a frame, System, or one that comes without a frame, Simple. A unique feature about Fleks3d is that you can print ABS with very little heat. I actually printed ABS with 10c on my print bed. This is good because Fleks3d recommends you use heat below 60c on the bed so you do not warp the build plate. I actually have a simple and laser cut an acrylic frame to fit my Robo3d perfectly. Another great feature is that you can sand you Fleks3d bed after many uses with high grit paper to give it new life and take out any scratches or burns left by your nozzle. An issue I found with all three products is if your print fails on the first few layers it is very hard to remove from the printer!

After reviewing all three products over the past couple months I have two different recommendations for anyone interesting in buying a build plate.

-First, I recommend Fleks3d to anyone that can just their heat on their bed and want to print with many different composites along with ABS and PLA.

-Second, I recommend a combination of Proto-Pasta’s build plate and BuildTak to anyone that cannot adjust their build plate heat.