dgkindy

1

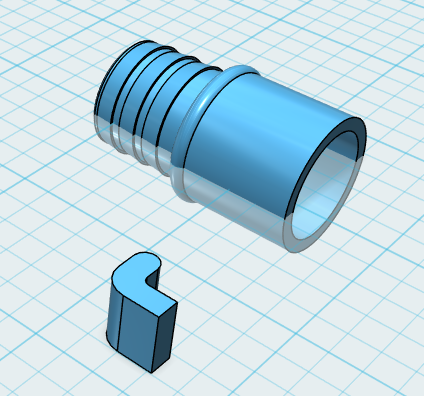

Working in 123D Design, I have created a cylinder shaped object which I need to cut a notch on opposite sides of the cylinder to lock onto two nubs on the corresponding part but if I just push an extrusion through the cylinder, the resulting hole will have angle on the slot as opposed to having the edge be at 90 degrees. Not sure how to apply the profile to the side of the cylinder and make the hole. I have attached an image of the part and the keyway that I am trying to apply to the cylinder.

I’m mildly confused by your statement: “push an extrusion through the cylinder, the resulting hole will have angle on the slot as opposed to having the edge be at 90 degrees”. Are you saying you want the SLOT at 90 degrees to the intersecting curve, or you just want a slot that is 90 degrees from the center? Normally, a slot at 90 degrees would be the same width all the way through. But a slot that is 90 degrees to the curvature of the surface would change based on depth…

If you want a standard slot (as if you cut it with a saw, for example), then put your cut on the center plane of the object, and cut through all the material. If you’re looking for the curved cut… you’d have to select the top edge (or insert a plane) and then use that to draw your profile, then cut it to depth. Actually, you could use that last method for a square cut as well, assuming you don’t want to have the bottom of the cut at a profile.

Hmm… Okay, I went and looked over the tutorials for 123design… looks like you’ll have to make an object that is what you want for a slot, then subtract it from your other part. Use the intersection tools.

Cheers!