Hi guys. I just got an M3d after my last printer broke and I realized most of the prints i was doing were really small any how so opted to get a smaller machine for my little studio.

So far i haven’t had much luck. Prints get a few layers in and start to peel up. Either won’t stick to the raft or they just start to delaminate from the print all together.

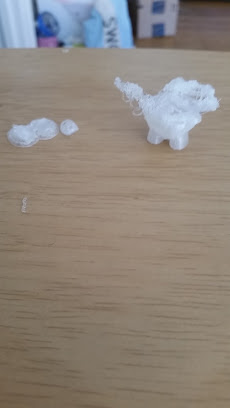

see my two attempts at Marven I have a few more now but seem I can only get the feet before it starts to mess up.

9 Likes

I have had some issues with printing large objects lately as well. It’s always a struggle when you have a printer with a none-heated print bed. What works for me is to use double sided tape. The print just sticks like its life depend on it.

I’ve haven’t been able to print a perfect copy yet either for the same reasons. The very first time I printed it, at least it completed. But it was slightly open at the very top… Every print I’ve tried after that one started drifting… Using painters tape it starts wobbling about WITH the tape sticking firmly to the feet but not the raft… So it gets all skewed…

Using a double sided film (3M 300LSE, made to attach glass to lcd screens) sooner or later it lets go anyway…

HAAM

4

Hello v,

Apply some glue stick from Dollarama (4/$1.00) to cover the bed.

Then put down one layer of blue painters tape on the bed.

Go over the tape with the same glue stick.

Works like magic.

Enjoy.

Ron

Do you have your face cover on the extruder head? My M3D was doing this too till I removed the cover now my layers stay together great. Also to secure my raft to the build platform I use the wife’s hair spray works great and after a few prints I just clean it off and re spray

Dave

what kind of material are you using? ABS or PLA? is it M3D filament or someone else’s? if it is other, then you may have to adjust temperature settings because it sounds like the layers aren’t bonding correctly. i’m using Sain Smart PLA and it works excellently.

have you taken a level to check and see if your printer is perhaps tilted? i found that my table was several degrees off and that would cause shifting. get an app for your phone to check if the print surface is level. it’s supposed to auto level, but it’s best to start with a surface as level as possible.

also, if having issues with print bed adhesion, use 90% alcohol in a spray bottle (to avoid contamination) and spray the surface and wipe with a clean cloth to remove any debris and human oils. fingerprints have killed enough of my prints to make me want to throw the printer out the window. someone recommended it on a site and i’ve had almost 90% print success on small prints. the larger prints are still problematic and if you do those, use RAFT and WAVE BONDING. i use WAVE BONDING on everything i print on my M3D.

The first step is making sure the bed is level. You really need to spend the time to fine tune your bed leveling. Go into the advanced calibration settings and run the test border. Adjust each corner until you get a smooth square, with even lines on each side. Don’t worry too much about each side (and corner) having a perfect 0.4mm thickness, just that each side has a nice even deposit. If you get thick globs or places where it thins out, then keep adjusting.

Once you are convinced your bed is level, the best trick is blue painters tape (specifically, 3M’s Scotch Blue 2090) on the print bed, and a THIN layer of glue from a glue stick (I recommend the washable Elmer’s one).

If prints still don’t stick, try tweaking the temperature settings for your filament, as has already been suggested. I find most PLA works best in the 200 degree range. Under the Advanced settings, you can set custom temperatures for various profiles.

Hope this helps!

HK3DP

8

Try using other filament. If results the same, paste a layer of solid glue from UHU or Pritt.

Mdikov

9

There’s couple of things I found affect this:

Line the print bed with blue painters tape. Then increase the height in advanced calibration by about .02. Or… Without tape on perform a drive system calibration. This may take awhile but it helps. You may also try manually increasing the temperature to around 197-199^Degrees Celcius (for pla). If none of these help, I also highly recommend not using the m3d filament but instead HatchBox filament on Amazon, it adheres much better and has much higher quality. Hope that helps

Utilisez-vous les supports ?

Le réglage de la hauteur de tête est-elle juste ( paramètre calibration ) ?

Salutations…

thanks. I did check the level My floor is apparently not straight, which means my table and printer were also not flat. I put a few shims underneath and have gotten it more level. Seems to be helping a bit. But the layers still seem to delamanate from each other. I am using the M3d filament will try to order some others. I am a bit worried to burn it if I put the temperature up to high. But I also wonder if there just isn’t’ enough filament coming out of the nozzle, as if it is clogged?

you can run the marvin as a test print (since it’s so small) and turn up the temp in 5C increments until you either get results that you want, or you need to try different filament. sain smart and hatchbox work great for me.

The wide 3M Tape on Amazon, and a better priced alternative

I had similar issues, i was using the internal spool setup, where the spool sits under the printbed. While it is nifty, and convenient for space. It was causing tension in my filament and resulting in the similar issues you are having. I would recommend, removing the filament and setting it up externally. There’s a great spool holder design that you can print on the m3d site.

Try the wave bonding feature. That might help.

Try the wave bonding feature. That might help.