Jewelry 3D printing applications

This article discusses how 3D printing is being used to produce high detail, custom jewelry through investment casting and direct metal printing.

Introduction

The production of jewelry is one industry that has embraced 3D Printing. Many jewelers now use the technology to disrupt the way things were done for hundreds of years. 3D printing is now used to create the patterns for investment casting and to print jewelry directly.

This article introduces how 3D printing can be used to produce jewelry, discusses the most common technologies and materials and presents several limitations.

Why use 3D printing?

There are several advantages to using 3D printing to produce jewelry. These include:

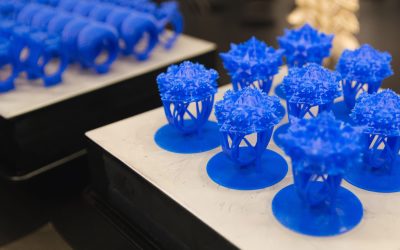

- Very complex designs can be created. Historically, jewelry casting patterns were carved from wax using CNC machines. 3D printing is not restricted by the limitations of CNC machining and is able to produce parts that have in the past were impossible to make. Designs can also easily be customized.

- With 3D printing, multiple patterns can be made at once and within a very short time frame. This has significantly reduced lead times as well as cost when compared to traditional pattern making techniques (wax CNC, aluminum molds for casting etc).

- 3D printing also allows multiple designs to be produced in a single print. This means it is very cost competitive pricing for low production volumes (an important issue for jewelry where customers typically want a one-off piece).

3D Printing techniques

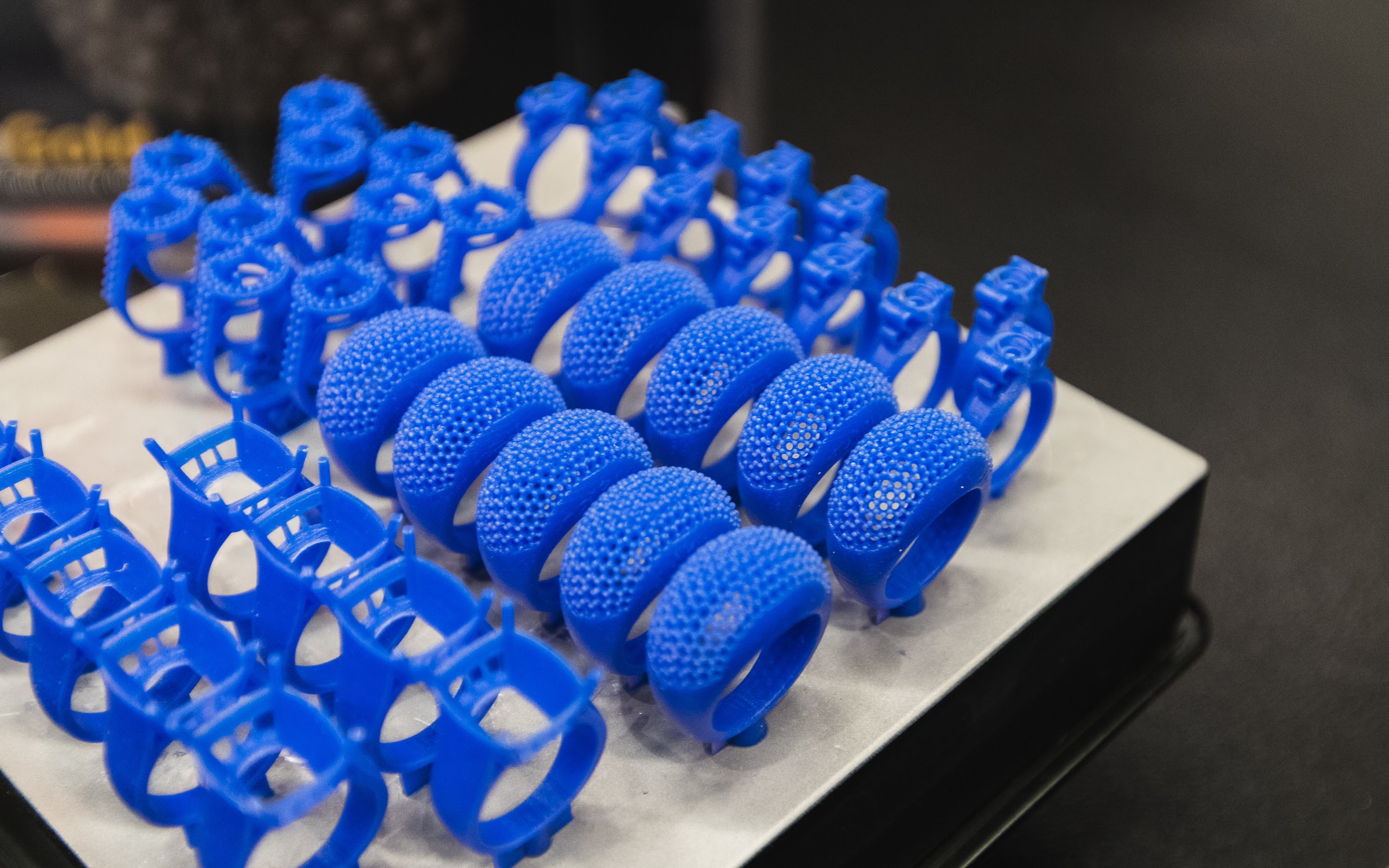

3D printing is typically used to create jewelry via 2 methods; investment casting and direct printing.

Investment casting

One of the most popular methods of producing jewelry via 3D printing is the investment casting process. Investment casting produces parts through an 8 step process:

There are several requirements for a 3D printing technology to successfully produce jewelry molds for investment casting. These are:

- The technology must be capable of producing parts with a very high level of detail and minute, intricate features.

- The material used to print the pattern must be able to be completely eliminated at the burnout/melt stage. Leftover remnants of the original pattern material have a detrimental effect on the quality of the final cast part. Because of this there are strict burnout procedures for most 3D printed castable resins.

Based on these requirements the two most suitable technologies and their associated materials for producing 3D printed patterns for investment casting are summarised below:

SLA/DLP SLA and DLP are both vat photopolymerization techniques that photocure a UV sensitive resin one layer at a time to produce a solid part. SLA and DLP are capable of producing smooth, high detail parts from castable resins that have a very low remaining ash percentage after burnout. Both SLA and DLP require support to accurately print parts. Support material generally has a detrimental impact on the surface of a print it is in contact with and must be removed once the print has been completed. Some of the more common SLA/DLP investment casting materials are presented in the table below:

| Technology | Material producer | Material name |

|---|---|---|

| SLA | Formlabs | Castable resin |

| SLA | DWS | DWS DC Series resins |

| SLA | 3D Systems | VisiJet SL Jewel |

| DLP | Envisiontec | PIC 100 C |

| DLP | B9 Creator | B9R-4-Yellow Resin |

| DLP | MoonRay | Castable resin |

DOD Drop-on-demand printing is a material jetting technique that uses 2 print jets; one to deposit a wax-like material over a build surface and another to deposit dissolvable support. The wax is deposited one layer at a time and a solid part is built up. DOD printers print at very high level of detail and offer several advantages over SLA/DLP printers including:

-

- Dissolvable support resulting in less post-processing and a better pattern surface finish.

- Patterns are printed with a wax-like material meaning the pattern is melted rather than burnt out eliminating the issues that arise with resin ash.

| Technology | Material producer | Material name |

|---|---|---|

| DOD | Solidscape | Solidscape Model and Support |

Direct printing

A much less popular method of producing jewelry via 3D printing is directly printing parts from metal powder. Parts are able to be printed via gold, silver or platinum alloys and then require a significant amount of post-processed to an appropriate finish. Direct printing of jewelry is generally more expensive than investment casting, even for one-off pieces, and requires a very high level of precious powder management.

DMLS/SLM Direct metal laser sintering (DMLS) or selective laser melting (SLM) are powder bed fusion techniques used for the production of metal parts. To accurately produce parts DMLS/SLM require a significant amount of support to be included on the part during printing. High temperatures result in high levels of stress meaning parts are often susceptible to warping or deformation. This leads to significant post-processing being needed to remove the support and finish the surface where it was attached.

| Technology | Material producer | Material name |

|---|---|---|

| DMLS | Cookson Precious Metals | ALNP000 18k 3N Yellow Gold Powder |

Limitations

Feature size

There are limitations on size of details (engravings) and features (prongs) that features are able to produce. These are summarized in the table below. All dimensions are in mm.

| Technology | Minimal details | Minimum feature size |

|---|---|---|

| SLA/DLP | 0.2 | 0.3 - 1 |

| DOD | 0.25 | 0.25 |

| DMLS | 1 | 1 - 3 |

Burn out remnants

Correct burnout is a critical step to ensuring a good quality cast part in any investment casting procedure. A burnout that is too quick can cause the resin to expand and combust damaging the surface of the investment and in turn the detail of the finished castings. A burnout that does not reach high enough temperatures can leave resin or ash inside the investment, affecting metal flow and the surface finish of your metal part. Information on the recommended burnout procedure for 3D printed pattern materials should be obtained from the supplier to improve the likelihood of a successful cast.

This article offers an insight into the recommended burnout procedure for Formlabs Castable Resin.

Support removal

For all process discussed in this article, support is a critical part of printers being able to accurately produce parts. While DOD technology uses dissolvable support, SLA and DMLS/SLM require the support to manually be removed. For these technologies, any surface that support is in contact with will require extra post-processing to achieve a smooth finish.

Loss of the handmade touch

There is some resistance in the jewelry making industry towards the adoption of the 3D printers as people feel it removes the “handcrafted” aspect of the profession. Jewelry often an intimate and personal product and the manufacture of parts by a machine has seen several large jewelry manufacturers not embrace the technology.

Rules of thumb

- SLA/DLP offers a cost-effective method for producing jewelry patterns for investment casting however the designs require support material and a strict burnout procedure must be followed to ensure full burnout of the resin.

- DOD is capable of producing investment casting patterns at a higher level of detail and does not require the strict burnout procedures required for SLA/DLP resins however it is more expensive.

- Direct printing of metal jewelry the most uncommon and expensive method for producing jewelry yet it offers the shortest production chain. Significant post-processing is required after the print is complete.