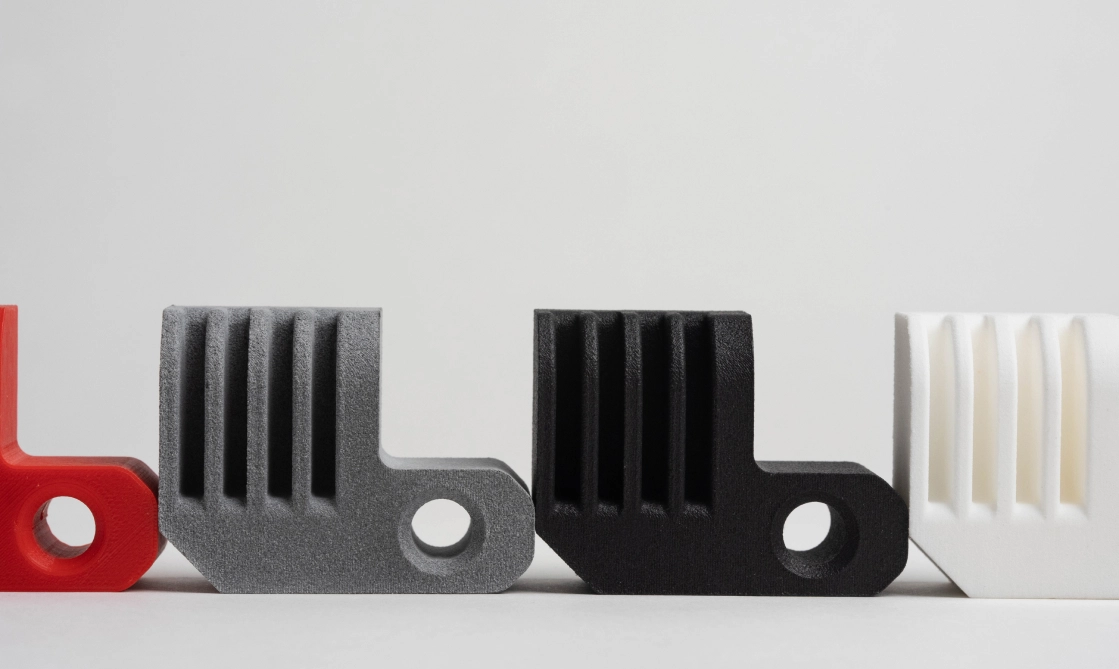

Explore the 3D printing technologies engineers use to manufacture prototypes and end-use parts.

Read our 3D printing guideManufacturing guides

Produce better parts with these comprehensive guides to the manufacturing technologies we offer at Protolabs Network. Based on our years of experience producing millions of parts, these best practices and tips will steer you through the production process.

Learn the basics of milling, turning and using multi-axis CNC machines to create accurate custom parts.

Read our CNC machining guide

Master the injection molding process for manufacturing at scale, from tooling and mold design to production runs.

Read our injection molding guide

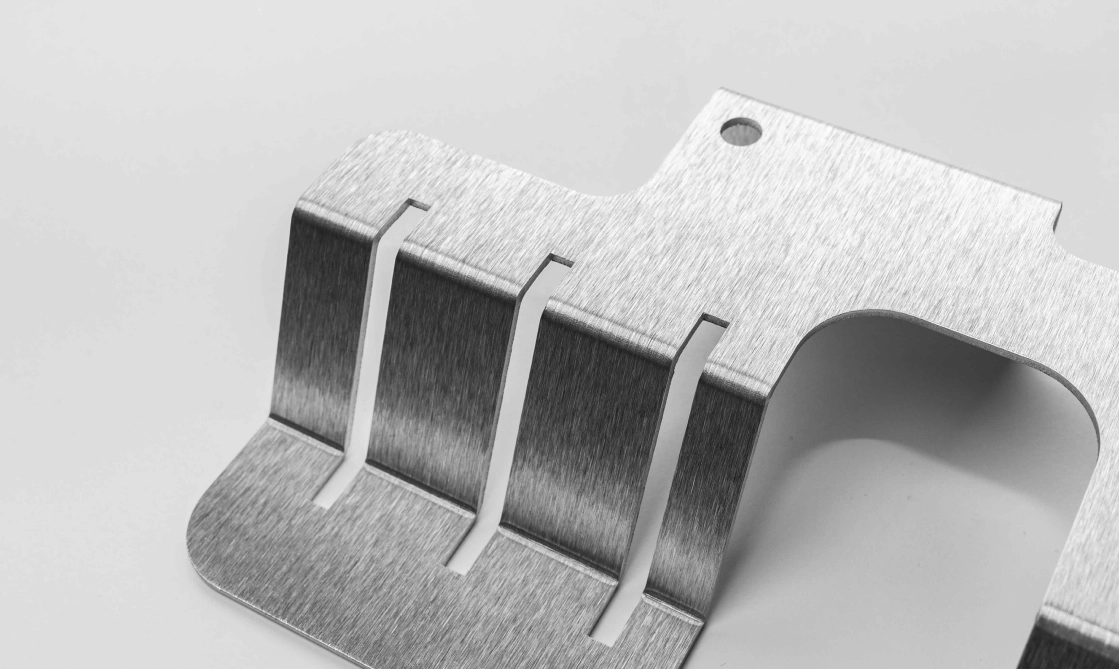

Find out about manufacturing custom parts using high-precision bending and laser cutting.

Read our sheet metal guide

Compare the technologies behind functional metal parts that can be 3D printed on demand.

Read our metal 3D printing guide

Choose plastics with the right properties for injection molding, 3D printing or CNC machining.

Read our plastics guidePut your parts into production today

Get instant quote